About this tour

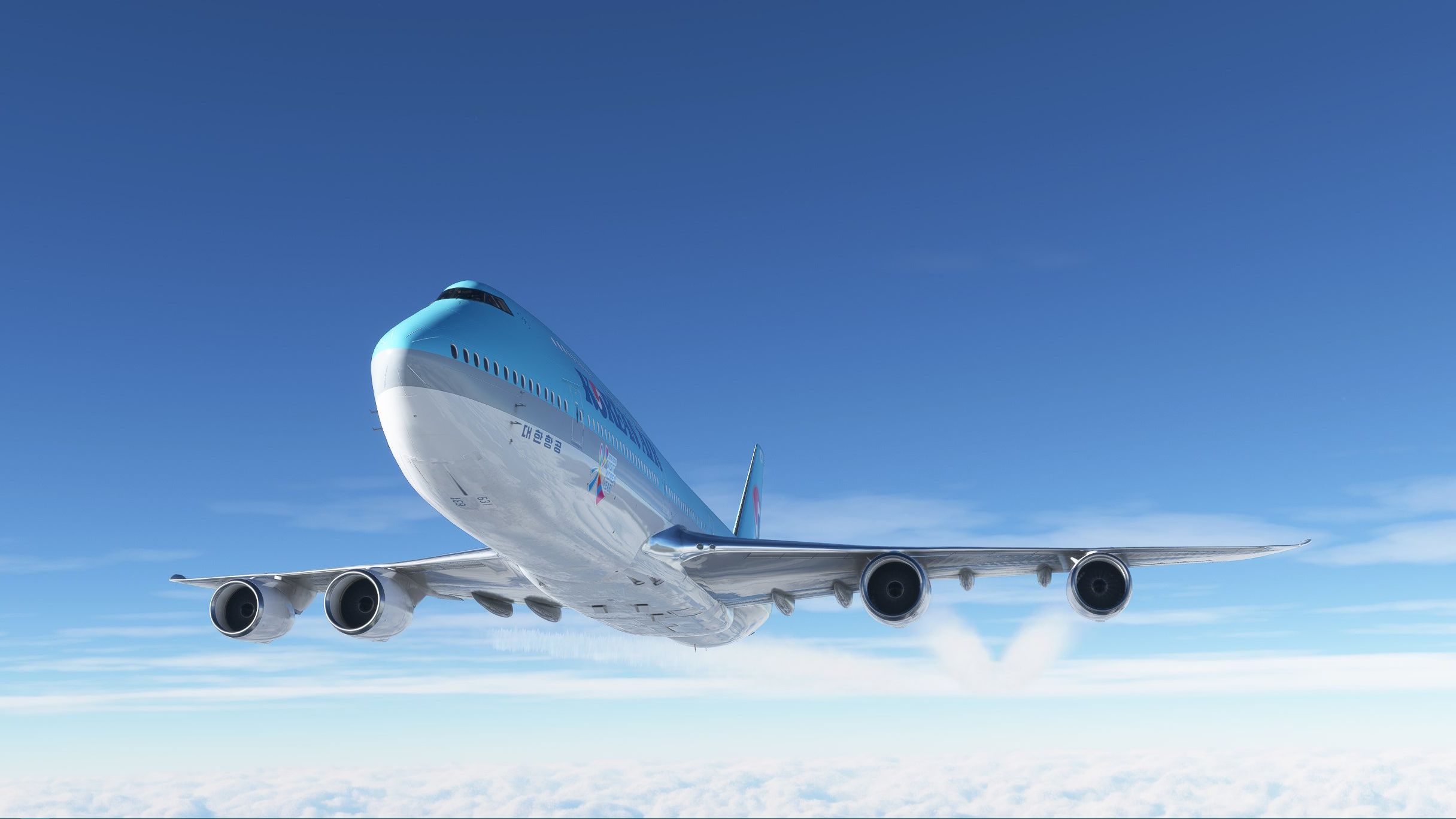

Fly the iconic airliner on busy cargo routes and select passenger services. Updated for 2022.

This is a tour of 42,627 nm (78,945 km) divided into fourteen legs.

To complete this tour, you will need to fly at least one route of each of the legs listed below. You will need to fly all legs using one of the aircraft types listed below. The type can differ between the different legs, as long as each individual route is flown using one of the aircraft types listed below.

You will need to fly all legs of this tours between 1 Jan 1990 00:00 and 31 Dec 2023 23:59 . Your last leg should have been submitted no later than 31 December 2023 23:59:00 UTC .

All legs need to be flown using one of the following aircraft types :

- Boeing 747-8 (B748/74H)

- Boeing 747-400 (B744/744)

- Boeing 747-400F (B74F/74Y)

- Boeing 747-8F (B74H/74N)

Leg 1: KJFK-RKSI

This is a leg of 5,995 nm (11,102 km) from John F Kennedy International Airport (JFK/KJFK) (Hub) to Incheon International Airport (ICN/RKSI) (Hub) .

Eligible routes

Choose any one of the routes below. Please take into account the conditions listed at the top of this page.

Leg 2: RKSI-WSSS

This is a leg of 2,502 nm (4,633 km) from Incheon International Airport (ICN/RKSI) (Hub) to Singapore Changi Airport (SIN/WSSS) .

We are not aware of any eligible routes. Please create a support ticket to notify us, so we can resolve this issue. Please note that there may still be eligible routes, which could be found by searching on our routes page .

Leg 3: WSSS-RCTP

This is a leg of 1,742 nm (3,226 km) from Singapore Changi Airport (SIN/WSSS) to Taiwan Taoyuan International Airport (TPE/RCTP) (Hub) .

Leg 4: RCTP-OMDW

This is a leg of 3,560 nm (6,594 km) from Taiwan Taoyuan International Airport (TPE/RCTP) (Hub) to Al Maktoum International Airport (DWC/OMDW) .

Leg 5: OMDW-EDDF

This is a leg of 2,626 nm (4,864 km) from Al Maktoum International Airport (DWC/OMDW) to Frankfurt Airport (FRA/EDDF) .

Leg 6: EDDF-ZSPD

This is a leg of 4,788 nm (8,868 km) from Frankfurt Airport (FRA/EDDF) to Shanghai Pudong International Airport (PVG/ZSPD) (Hub) .

Leg 7: ZSPD-EHAM

This is a leg of 4,817 nm (8,921 km) from Shanghai Pudong International Airport (PVG/ZSPD) (Hub) to Amsterdam Airport Schiphol (AMS/EHAM) (Hub) .

Leg 8: EHAM-OEJN

This is a leg of 2,431 nm (4,502 km) from Amsterdam Airport Schiphol (AMS/EHAM) (Hub) to King Abdulaziz International Airport (JED/OEJN) (Hub) .

Leg 9: OEJN-HSSK

This is a leg of 525 nm (972 km) from King Abdulaziz International Airport (JED/OEJN) (Hub) to Khartoum International Airport (KRT/HSSK) .

Leg 10: HSSK-HKJK

This is a leg of 1,049 nm (1,943 km) from Khartoum International Airport (KRT/HSSK) to Jomo Kenyatta International Airport (NBO/HKJK) (Hub) .

Leg 11: HKJK-EHAM

This is a leg of 3,610 nm (6,685 km) from Jomo Kenyatta International Airport (NBO/HKJK) (Hub) to Amsterdam Airport Schiphol (AMS/EHAM) (Hub) .

Leg 12: EHAM-KORD

This is a leg of 3,575 nm (6,620 km) from Amsterdam Airport Schiphol (AMS/EHAM) (Hub) to Chicago O'Hare International Airport (ORD/KORD) .

Leg 13: KORD-PANC

This is a leg of 2,470 nm (4,574 km) from Chicago O'Hare International Airport (ORD/KORD) to Ted Stevens Anchorage International Airport (ANC/PANC) .

Leg 14: PANC-KJFK

This is a leg of 2,938 nm (5,441 km) from Ted Stevens Anchorage International Airport (ANC/PANC) to John F Kennedy International Airport (JFK/KJFK) (Hub) .

- svg]:stroke-accent-900">

Explore the gauges, levers, and history of a 747′s iconic cockpit

By Rob Verger

Posted on Sep 19, 2019 5:43 PM EDT

8 minute read

The cockpit of a British Airways Boeing 747-400 is a beautifully complex place where a handful of analog gauges live side-by-side with digital displays.

Among the vast array of system switches and controls in the worn flight deck, some parts are easier to understand than others. Four Rolls Royce engines power the giant 747 aircraft, hanging off wings that span about 211 feet—and in the center of the cockpit are four ivory-colored thrust levers, one for each engine.

I’m a journalist, not a pilot, but I’m sitting in the captain’s seat on the left side of the flight deck. Mark Vanhoenacker, a senior first officer with British Airways, author of air-travel books, and a columnist for the Financial Times , is in the seat to my right.

“It’s as basic as it can be,” Vanhoenacker says casually, then pushes those four thrust levers forward with one hand. A moment later he moves them back where they were. “Push them forward, you go faster; pull them back, you go slower.”

Our airliner’s parked at a gate at John F. Kennedy International Airport in New York City, and the engines are off, so of course, we don’t change speed. Earlier that morning, the vessel had flown in from London’s Heathrow, typically a seven-hour-plus flight. Later that day, it will cruise back.

I’m there to talk to Vanhoenacker about his latest book, How to Land a Plane , but also—let’s be honest—to just spend some time in the cockpit with a seasoned aviator who showed me some of its cavernous interior during an interview in late May. To be in a 747 meant the chance to see the nerve center of an iconic aircraft up close—a plane that’s the basis for Air Force One , that people love flying in and staring at, and that helped make air travel more affordable—as airlines fly them less and less. (Vanhoenacker doesn’t fly the 747 now; other pilots steered the plane in from London that day.)

Sitting in the cockpit, some of the flight controls are easy to grok, even for a person who’s never ferried hundreds of passengers through the skies. Both seats have a control column in front of them, with a wheel, on top. Pull the wheel and the column back towards you, and the plane’s nose pitches up . Push it forward, the reverse happens. Turn the wheel to the left, and the plane banks left. A pair of pedals at each of our feet control the rudder.

A single small lever, with fading green paint and a miniature wheel on the end, raises and lowers the enormous aircraft’s landing gear. (Get it—a lever with a little wheel on it controls the wheels?) Another lever with a handle shaped like a wing controls the craft’s flaps and slats, which allow the plane to generate more lift and thus fly more slowly. Upon it is simply written “FLAP.”

We each have a monitor in front of us—the primary flight display—that indicates in colors such as green, purple, and blue crucial information like the aircraft’s airspeed and altitude. Not far from those screens are three classic-looking gauges that duplicate that information in analog form. They’re a form of redundancy, which is the name of the game in aviation .

“This is almost literally what you’d see on a Cessna,” Vanhoenacker says, pointing at those gauges.

But this is no Cessna. For one, it seats 275 people, measures about 232 feet from tip to tail, and cruises at 85 percent of the speed of sound. For another, the flight deck boasts a small bunk room that sleeps two, plus a lavatory, so the crew don’t need to leave the cockpit for a bathroom break.

This particular 747 first flew in 1999. In 2019, it’s not ancient—but it sure does look old, in a capable, dad-bod kind of way.

Let’s land this baby

Vanhoenacker’s latest book, How to Land A Plane , is a good choice for anyone who’s fantasized about suddenly having to get an aircraft safely down on the ground; the book will tell you some of what you need to know.

“Spoiler alert,” Vanhoenacker says before we get on the plane. “You cannot learn to land a plane by reading a book, but hopefully it’s a fun way of thinking about what pilots think about all the time.”

And indeed it is: The slim volume walks you through some of the basics of flight and landing, from how to recognize a cluster of instruments known as the “six pack” to knowing what purpose the PAPI lights near the runway serve.

How to Land a Plane follows Skyfaring: A Journey with a Pilot , which The New York Times said “makes jet travel seem uncanny and intriguing all over again.”

“I was thinking that there is that poetic side of flying,” he says, “and then there’s also a really, really technical side, and very, very mechanical side.” This new book is all about that practical side.

And on the subject of landings, keep in mind that there’s a good chance that every landing you’ve ever experienced on a commercial flight has been executed by a pilot actually landing that plane by using the flight controls (unless you regularly fly in and out of an airport frequently socked in by fog, like in London or Delhi). In a world of autopilot, artificial intelligence , and self-driving cars , some might assume that planes are constantly landing themselves. And while they can, it’s rare that they do.

The main reasons an airliner will land itself is if the runway is enveloped in fog or flying snow so thick that a pilot can’t see the tarmac. And setting that process up is a pain. “When we get a weather forecast that reports that kind of fog, there are groans in the fight deck, because it’s a lot more work to land it automatically,” Vanhoenacker says. It’s rare to do that—he estimates it happens just once a year for him. And airliners don’t ever take off automatically, either; the pilot always flies it off the runway.

The autopilot does, however, allow pilots to program the route into the aircraft in advance, so that the plane automatically makes the turns it needs during the cruise phase of the flight. That type of assistance frees up cognitive bandwidth for pilots, who need to consider other factors, like what to do if a passenger gets sick or if they need to land elsewhere. In essence, it allows the crew to focus on the “overall management of the flight,” Vanhoenacker says—the mundane yet essential stuff like making radio calls or picking a new route.

An aircraft for “thin” routes

Vanhoenacker flies the 787 Dreamliner, a more modern and fuel-efficient airliner, now. His new aircraft is advanced enough that the pilot can use a cursor on a screen to tell the plane where to go. “On the navigation display, you can see it’s painting where the storms are, and you can point and click to a position away from the storm” to direct the plane there, he says. “The 747 does not do that.”

When you switch the autopilot off, a quick and repetitive siren-like thrum plays to alert the pilots.

Airlines like British Airways and Lufthansa still operate 747s, but the giant four-engine planes are on the decline. From a financial perspective, carriers may prefer more fuel-efficient two-engine craft like the Airbus A350 and the 787, which are also smaller than huge planes like A380 . (Boeing still makes the most modern version of the 747, the 747-8, but the orders they have on hand are for the freighter version.)

A rule of thumb for fuel consumption on a 747 is that it will burn about 11 tons of fuel per hour. The 787 burns about half that in the same period but still carries more than 50 percent of the passenger load of the 747. “Most airlines are laser focused on managing fuel consumption,” says Andrew Buchanan, a vice president at Oliver Wyman, a firm that consults for airlines. That, and Buchanan notes that aircraft like the Dreamliner are good for what he describes as “long thin routes”—an epically long journey that skips the traditional hubs and doesn’t carry as many people as an Airbus A380 would. Example: Air New Zealand operates a long flight between Chicago and Auckland on a Dreamliner.

In other words, the aviation landscape has changed since Barry Lopez, in his classic 1995 essay titled “Flight” for Harper’s magazine, wrote : “The Boeing 747 is the one airplane every national airline strives to include in its fleet, to confirm its place in modern commerce, and it’s tempting to see it as the ultimate embodiment of what our age stands for.”

Fly-by-wire

Another major difference between a 747-400 and the Dreamliner is that the latter is what’s known a fly-by-wire aircraft. In the 747-400, when the pilot moves the controls, actual physical cables convey that motion to the rest of the plane, so the surfaces on the wings, like ailerons, can move appropriately. On a fly-by-wire plane, those instructions are passed electronically—that’s the “wire”—along to the rest of the plane. In brief, on the Dreamliner and others planes, computing power sits between the pilot and the actual motion of the aircraft. On our 747, it’s mechanical. (Boeing 747-8s are fly-by-wire.)

Being back in a 747 is enough to trigger some serious nostalgia for Vanhoenacker, who flew them for about 11 years. “We’re sitting on the flight deck of this totally iconic, beautiful aircraft that changed the world,” he reflects; it’s a plane famous enough to have flown its way into the lyrics of songs by the likes of Joni Mitchell and played a key role in the film Inception .

“I will never sit in this seat again in my life,” he adds, as our time in the cockpit draws to a close, unless he happens to show another curious journalist like me around. “It’s sad, isn’t it?”

Latest in Aviation

How drones and ai could help farmers fight a stink bug invasion how drones and ai could help farmers fight a stink bug invasion.

By Mack DeGeurin

Amazon’s Prime Air delivery drones get a major FAA clearance Amazon’s Prime Air delivery drones get a major FAA clearance

By Andrew Paul

Let's Tour Together

Step inside the world's largest factory for a behind-the-scenes look at the Boeing Everett Factory and 777 assembly line. Each tour is an 80-minute guided experience with a front row view of current airplane production, the Everett site’s history and the central role it plays in the future of commercial aviation.

Pro-Tip: Tickets sell out quickly. We recommend booking tickets in advance, either online or through the Call Center: +1 (800) 464-1476

Tour Schedule: Offered Thursday – Monday. Select 'Buy Tickets' to check availability.

Know Before You Go

Safety requirements.

- Children/Youth must be at least 4 feet (48in/122cm) tall to go on the tour.

- Carrying children on the tour is not allowed for safety reasons.

- Children/Youth under 16 must be accompanied by an adult.

Restricted Items

This is a hands-free tour. Complimentary lockers are available to use in the lobby. Please store all belongings before your tour time begins. Items NOT allowed on the Boeing Everett Factory Tour:

- No purses, handbags, waist pouches or backpacks

- No binoculars and electronics including cameras, video equipment or drones

- No phones or tablets

- No food or drinks

- No smoking or vaping

Refunds and Restrictions

- If guests do not arrive promptly for their scheduled tour the reservation will be forfeited*. We strongly recommend guests arrive at least 30 minutes before their tour start time.

- Refunds will be provided with at least 24-hour notice of cancellation. No refunds will be made within 24 hours of your scheduled tour.

- In order to request a reservation modification of any kind, please call Boeing Future of Flight Customer Service at +1 (800)-464-1476 .

* If an emergency arises, we will attempt to reschedule your tour if you call at least one hour in advance of your scheduled tour time (depending on availability).

The Boeing Company reserves the right to cancel the tour at any time for any reason.

Accessibility

- Boeing Future of Flight is an accessible facility. Please contact Boeing Future of Flight Customer Service in advance at [email protected] or call +1 (800) 464-1476 for special accommodations requests, including booking our wheelchair-accessible bus tour. For more information regarding our accessibility accommodations, please visit our Accessibility page.

- Participation on the Boeing Everett Factory Tour requires traveling approximately .3 miles (.5km) round trip. There are flights of stairs to navigate; however, elevators are accessible on all floors at Boeing Future of Flight and the Boeing Everett Factory Tour.

Restrooms are not available during the tour. Please plan ahead by using the restrooms at Boeing Future of Flight before your tour start time.

Stay in the Know!

Join our email list to be the first to know about new experiences, events and promotions.

- Air & Spacecraft

- Aircraft Details

Boeing 747-121

- Step Inside (VR)

The growing worldwide demand for air travel during the 1960s led Boeing to launch the 747, the first wide-body jet. Developing what was then the world's largest passenger aircraft was a formidable undertaking, requiring the company to risk much of its net worth. But the gamble paid off – over 1,500 units have been produced. With its massive size and signature upper deck "hump," the iconic 747 is one the most recognizable aircraft in the world. It triggered a revolution in air travel and represents a significant milestone in the evolution of aviation design.

The leviathan 747 required an all-new factory, which was built almost simultaneously with the first 747 at Paine Field in Everett, Washington. First flight occurred on February 9, 1969, followed by an extensive test program. The first 747 engine, the Pratt & Whitney JT9D, was an equally challenging engineering effort; it experienced numerous problems in initial service.

The 747 quickly became a mainstay of the world’s international airlines. Continued development in the ensuing years has increased payload, range, and capability with multiple 747 variants. A freighter model, with a large nose cargo door, allows outsized payloads to be carried. A "Combi" was soon offered to allow simultaneous carriage of passengers and cargo on the main deck. A shortened version (747SP) debuted in 1976, capable of very long range flights. The 747-300 followed in 1982, with an extended upper deck. In 1989, a major upgrade was introduced in the form of the 747-400, with a modernized two-crew flight deck and improved performance. The 747-8, with all-new wings and engines, entered service in 2011.

The airplane proved to be highly flexible, performing many missions that were not part of its original design specifications. Two 747-100s were modified to become Shuttle Carrier Aircraft for the NASA Space Shuttle Program. Several aircraft were produced to serve as U.S. Air Force "command post" platforms, designated E-3 and E-4. In 1990, two 747-200Bs were modified as VC-25As to serve as Air Force One, the U.S. Presidential aircraft. Other unique modifications include the enlarged "Dreamlifter" for 787 components, the YAL-1A Airborne Laser Testbed, and the Stratospheric Observatory for Infrared Astronomy (SOFIA).

The Museum's aircraft was the first 747 ever built, known as RA001. After 747 certification testing, the aircraft served for many years as a company testbed for technology development and new engine programs for other Boeing commercial jets, including the Pratt & Whitney PW4000 for the Boeing 777. Planning for eventual donation to the Museum began in the mid-1980s. The aircraft's final flight occurred on April 6, 1995, when Boeing officially donated RA001 to the Museum after 5,300 flight hours. Still configured in its flight test configuration, it was extensively restored in 2013 and 2014.

360˚ Panoramas

Cockpit Lounge Lower Bay

Matterport 3D Tour

Boeing 747 Matterport 3D Tour

Aviation Pavilion

Now Showing<br>Space - The New FrontierRunning time: 25 minutes<br>Showtimes: 10:30 AM; 11:30 AM;...

sign up for our newsletter

This website may use cookies to store information on your computer. Some help improve user experience and others are essential to site function. By using this website, you consent to the placement of these cookies and accept our privacy policy.

EVENTS AT COTSWOLD AIRPORT

Regular tours.

Since March 2022, Negus has been open to the public for self-guided tours most Wednesdays and Saturdays, subject to availability.

Follow the link below to book tour tickets.

Dates are released a few weeks in advance.

Tours will not be running during November and December due to the Immersive Theatrical Christmas Experience hosted onboard.

Take a self-guided tour around the aircraft, observing all the original features left in place by British Airways before exploring our new events section in the economy cabin.

- Latest News

Take a Virtual Tour of Network Aviation’s B747-400F Aircraft

We identified an exciting opportunity in the industry to give our customers and clients an in-depth look at how a Network Airline Management Boeing 747 freighter aircraft looks from the inside. Take a virtual tour of a B747-400F aircraft now!

In partnership with Mike Rivett from Fotomotion, an incredibly detailed 360° internal scan of the aircraft was captured with highly specialist cameras which allows us to take a view like very few have seen before!

This interactive virtual tour includes a full-length view of the main deck, on one of our B747F aircraft, and clearly highlights the different cargo positions such as A1, Q6 and all the Q7 positions as well as the main cargo door and roller bed facility. This allows those who haven’t stepped foot inside a freighter aircraft an intricate look at how and where cargo is loaded and positioned on our aircraft.

Various time-lapse videos demonstrate how precise and calculated it is to load large and heavy pieces of cargo on board. The B747-400F Aircraft virtual tour also includes a look at the upper deck including an expansive view of the flight deck as well as the crew rest area.

Related News

Sri Lankan Airlines Appoints NAS as GSA in the UK Sri Lankan Airlines has appointed Network Airline Services…

Network Cargo Management Appointed as GSSA for JetBlue in New York Network Cargo Management has been appointed as…

Network Airline Services Appointed as GSSA for FlyDubai in Kenya Network Airline Services has been appointed as the…

- Go to navigation

- Go to main content

- Go to search

- Go to footer

Main content

Boeing 747-8.

Seat maps Boeing B747-8

Sample illustration b747-8 (8 first / 80 business / 32 premium economy / 244 economy).

Seat maps of the Boeing B747-8 to download

Technical data.

Simple Flying

Ed force one: the story of the iron maiden boeing 747 then and now.

Your changes have been saved

Email Is sent

Please verify your email address.

You’ve reached your account maximum for followed topics.

- Iron Maiden's iconic 'Ed Force One' planes, a Boeing 747 and Boeing 757, were used for their world tours and piloted by lead vocalist Bruce Dickinson.

- The Boeing 747, known by the registration TF-AAK, is now owned by Air Atlanta Icelandic.

- The first 'Ed Force One' Boeing 757, registered as G-OJIB, is now employed by FedEx Express, while the second was scrapped in 2011.

Iron Maiden is one of heavy metal’s most recognizable bands worldwide. Over the years, they have achieved superstar status with music hits such as Run to the Hills , The Trooper , Fear of the Dark , Hallowed be Thy Name and many more. In the avgeek world, they are also known for having two unique stories. First, their lead vocalist, Bruce Dickinson, holds an airline transport pilot’s license. Second, Iron Maiden used a Boeing 747-400 and a Boeing 757 for three tours. These planes are better known as the ‘Ed Force One.’

The ‘Ed Force One’

Perhaps the first question is, why is it called Ed? That is related to Eddie the Head, Iron Maiden’s mascot, a perennial fixture of the group’s artwork, appearing on all their album covers.

Throughout the years, the ‘Ed Force One’ has been everything a celebrity endorsement should be. Beautifully liveried and piloted by Bruce Dickinson himself, the aircraft registration TF-AAK made star-studded appearances all over the world.

The Queen of the Skies has a cult-level fan following, so when a band with similar brand status was hooked up with its very own Boeing 747 , it was a match made in heaven. Nicknamed 'Ed Force One,' TF-AAK took the band around the globe on the 'Book Of Souls' world tour, frequently piloted by legendary frontman Bruce Dickinson.

Of course, it wasn't the first plane Iron Maiden had at its disposal. From 2008 to 2009, a Boeing 757 with tail number G-OJIB took the band on tour for the Somewhere Back In Time World Tour. And, in 2011, G-STRX was liveried up in The Final Frontier World Tour to become the newest Ed Force One.

Despite the band's love for the smaller Boeings, nothing could compare to the Queen of the Skies for Dickinson. Speaking to Blabbermouth in 2016, he said the 757 was just not big enough anymore. Considering the band's needs, he explained:

“The [757] is just not big enough for what we’ve got in mind in terms of a show. So what we’ve got onboard at the moment is the stage show … Everything we need will be on the airplane, and all the technicians and baggage and everything else. We’re going all around the world [from] Perth, Australia to Cape Town, Shanghai to New Zealand. We’re really going ’round the planet.”

What has happened to the ‘Ed Force One’ ever since?

Iron Maiden employed the Boeing 757s and then the 747 only for select tours . Since then, the planes have gone to other endeavors. At the time of writing (September 2023), it is unknown if Iron Maiden will ever employ the ‘Ed Force One’ for future tours.

According to data from ch-aviation, the 747 registration TF-AAK is a 20.54-year-old aircraft owned by Air Atlanta Icelandic. It is currently stored at Kemble Cotswold (GBA) in the United Kingdom. Unfortunately, the plane is set to be scrapped, putting an end to its history.

The 747 was first delivered to Air France in 2003. The French company operated it until 2015 with the registration number F-GITH. Then it went to Air Atlanta Icelandic, who wet-leased it to Iron Maiden but also operated other flights. For instance, in 2016, it flew 350 Icelandic football fans to Marseille, France, for the country’s Euro 2016 fixture against Hungary.

After its stint with Iron Maiden, Air Atlanta Icelandic leased the aircraft to Saudi Arabian Airlines. When it joined the fleet, TF-AAK saw regular service with the airline, flying between Jeddah and several key destinations, including Surabaya, Addis Ababa, and Dhaka. Sadly, the onset of the coronavirus pandemic forced Saudia to park the jet up in March 2020. This saw it join two of its counterparts in storage in Jeddah.

The aircraft last operated in 2022. Last year, the 747 could be seen flying often between New York, Maastricht, and Dubai, according to data from FlightRadar24.com.

And the 757s?

Of the three ‘Ed Force Ones,’ only the first one continues to operate nowadays. This plane, registration G-OJIB when it flew with Iron Maiden, is currently employed by FedEx Express, with a registration number N938FD. It is a 34.52-year-old aircraft first delivered in 1989 to Air 2000. For years, it alternated flying for Air 2000 and Canada 3000 Airlines before going to Skyservice Airlines and then First Choice Airways in 2004. Then Astraeus acquired it in 2006 and had it until its bankruptcy when it went to FedEx Express.

If you’re wondering what happened to the second ‘Ed Force One,’ the Boeing 757 registered as G-STRX, we have some unfortunate news. The plane was scrapped in 2011 after amassing over 55,000 flight hours flying for four different operators. Canada 3000 Airlines operated it between 1992 and 2001. Then, National Airlines had it in 2002 before going to Omni Air International from 2003 to 2008. Finally, Astraeus flew it between 2008 and 2011. When the company went bankrupt, the aircraft went down with it.

Other rock bands with their own planes

One of Iron Maiden’s songs has the following verse: Fly on your way, like an eagle / Fly as high as the sun / On your way, like an eagle / Fly and touch the sun. This verse is aptly appropriate for the airline’s ‘Ed Force One,’ which indeed flew like an eagle all over the globe. Yeah, I know the song’s name is Flight of Icarus, and the ‘Ed Force One’ didn’t have an ending like Icarus’ (fortunately), but the verse remains appropriate.

Nowadays, many musicians own their own aircraft. However, most of these planes are private jets, with only a handful of artists owning true commercial jetliners. Perhaps one of the most known planes to be used by touring musical artists was The Starship , a Boeing 720 that carried Led Zeppelin, the Allman Brothers Band, The Rolling Stones, Deep Purple, and Alice Cooper in the 1970s. That’s quite the line-up. The Rolling Stones also had a Boeing 737 . Even before that, Elvis Presley owned a Convair 880, which was purchased from Delta Air Lines.

Did you ever see any of Iron Maiden’s ‘Ed Force Ones’? Would you like to see the group operate a new ‘Ed Force One’ in the future? Let us know in the comments below.

Source: ch-aviation , FlightRadar24.com , Blabbermouth .

- Iron Maiden 747

The new Air Force One won't fly until 2026 — years after the military Boeing 747 was supposed to first take flight

- Boeing and the US Air Force face further delays on their multibillion-dollar Air Force One project.

- The first flight of the new Boeing 747-8i has been pushed back 16 months to March 2026.

- This is yet another delay and Boeing has already suffered over $2 billion in overrun costs.

Boeing and the Trump Administration struck a $3.9 billion deal in 2018 to replace the country's aging 747 presidential fleet with two new Air Force One planes. They're already years behind schedule and now expect further delays.

An Air Force spokesperson told the military website Breaking Defense that the first flight of the next-generation Boeing 747-8i — set to replace the old 747-200Bs first put into service in the early 1990s — has been pushed back 16 months from this November to March 2026.

The spokesperson said Boeing is creating a revised schedule, expected later this summer, noting it "may result in changes to any dates provided." It's unclear when the deliveries will now occur.

In a statement confirming the news to Business Insider on Friday, the USAF said the latest delay was due to a mix of things, including "impacts from the COVID-19 pandemic, interiors supplier transition, manpower limitations, wiring design timelines, and projected test execution rates."

Boeing declined to comment.

Boeing initially expected to deliver the first new 747 in late 2024. However, similar problems, including a bankrupt supplier, forced Boeing in 2022 to reschedule the first delivery for September 2026 at the earliest and the second for February 2027.

At the time, the USAF provided a one-year buffer for the planes' delivery, pushing the second's delivery to as late as 2028. This means the eventual delivery of the new VIP fleet will be at least three to four years late, and possibly more with the latest delay announcement.

Related stories

According to Breaking Defense, ground-based subsystem testing to "power on" the plane is among the delays. The test was originally scheduled for May 2024 but is now set for July 2025.

Once eventually put into service for presidential use, the new VIP fleet will consist of bigger and more fuel-efficient 747-8i planes. The planes were originally destined for the now-defunct Russian carrier Transaero 2013 but were never delivered.

However, the old 747s are flying later than expected, thanks to continued program problems. In 2022, the Wall Street Journal reported that continuing to fly the old fleet may cost taxpayers $390 million.

The setbacks have already cost Boeing more than $2 billion, raising the total project expense to around $5.3 billion.

Boeing's financial strain stems from the fixed-price agreement it made with the Trump Administration, which made the manufacturer responsible for any overrun costs.

Boeing CEO Dave Calhoun said during a 2022 investor call that the deal posed "a very unique set of risks that Boeing probably shouldn't have taken" but remained committed to delivering the aircraft.

Issues with the current fleet

The call sign "Air Force One" applies to any aircraft carrying the president, but it is most directly associated with a specially configured 747 known as VC-25 . This aircraft is unlike any standard 747 and has a number of added capabilities, ranging from electronic and communications equipment to an executive suite.

The new VC-25B program, based on the 747-8i, will replace the Air Force's current VC-25A fleet. These aging aircraft face "capability gaps, rising maintenance costs, and parts obsolescence as it ages beyond 30 years," according to a Department of Defense report .

"The Boeing 747-8 aircraft will be uniquely modified to provide the President, staff, and guests with safe and reliable air transportation with an equivalent level of communications capability and security available in the White House," the report said.

The modifications will include an "electrical power upgrade, dual auxiliary power units that are usable in flight, a mission communication system, an executive interior, military avionics, a self-defense system, autonomous enplaning and deplaning, and autonomous baggage loading," the report added.

The VC-25B fleet is also slated to have a longer range, cruise speed, and maximum takeoff weight than its predecessor .

Watch: The true cost of America's war machines

- Main content

- Museum Events

- Host An Event

- Dates: 27 – 27 Dec, 2022

- Email: [email protected]

- How to find us: After you buy your admission ticket in the Museum lobby, meet under the 747 plane at 1 pm. Tour lasts about 45 minutes.

- Phone: 404-715-7886

Want an overview of the Museum's 747 Experience? Take a tour! On the 2nd and 4th Tuesday of each month, we offer a free guided tour with normal paid admission to the Museum.

Tours begin promptly at 1pm, and last about 45 minutes. Reservations are not accepted.

This tour highlights the exterior of the aircraft and its interior exhibits. Tour is handicap accessible, but will require a trek across the parking lot. Meet up under the plane to start the tour.

Movie Showing: The Steepest Climb

Paper planes & pops.

- Hours & Calendar

- Visitor Tips

- Group and School Visits

- Service Animals

- Brand Style Guide

- Privacy & Security

- First in the Air

- Aircraft By Type

- Delta Brand

- First Flights

- Family Tree

- 747 Experience

- Collections

- Support the Museum

- Donate Objects

- Sponsorship Opportunities

- Our Sponsors

- Job Opportunities

It’s a bird! It’s a plane! No, it’s Superman strolling the streets of Cleveland (photos)

- Updated: Jun. 26, 2024, 12:51 p.m. |

- Published: Jun. 24, 2024, 9:36 a.m.

- Joey Morona, cleveland.com

CLEVELAND, Ohio -- Superman is ready for his Cleveland closeup. David Corenswet, the actor portraying Clark Kent in the new “Superman” movie currently filming in Downtown Cleveland, arrived on set early Monday morning to shoot scenes along a closed section of Superior Avenue that’s been prepped for days to be transformed into Metropolis.

Corenswet was seen dressed in a black cape strolling along the street and checking out the set, which is strewn with prop rubble and wrecked cars, and appears to be ready for shooting an explosive action scene. If you look closely, you can see the collar of his Superman suit underneath the cape.

Earlier, Lois Lane actress Rachel Brosnahan arrived on set under the cover of umbrellas, shielding her identity from the crowd of onlookers hoping to get a glimpse of the production.

More superman movie cleveland

- ‘Superman’ director, crew zig-zag around the CLE on Friday, prep for week-long shoot on Public Square (photos, video, spoilers)

- Cleveland is the birthplace of Superman: Here’s how to tour all his significant spots in the city

- ‘Terrific’ scenes from ‘Superman’ film captured during Thursday’s CLE shoot (photos, video, spoilers)

- All the actors who have played Superman, from Kirk Alyn to David Corenswet

- ‘Superman’ crews begin readying Public Square for extended film shoot (photos)

Director James Gunn appeared around 9:30 a.m. to go over the scene with crew members and background actors dressed in military gear. Another set of extras then took their places for a rehearsal on a futuristic-style staircase connected to a platform draped in a blue screen, indicating it would be later replaced with CGI.

This reboot of “Superman” focuses on a younger version of the Man of Steel than DC’s previous franchise with Henry Cavill. In addition to Corenswet and Brosnahan, the cast features Nicholas Hoult as Lex Luthor and Edi Gathegi as Mister Terrific.

“Superman” flies into theaters July 11, 2025.

If you purchase a product or register for an account through a link on our site, we may receive compensation. By using this site, you consent to our User Agreement and agree that your clicks, interactions, and personal information may be collected, recorded, and/or stored by us and social media and other third-party partners in accordance with our Privacy Policy.

- Share full article

Advertisement

Supported by

Southwest Plane Begins Descent Too Early Over Oklahoma City

Its low altitude had triggered an automated warning and startled some residents near Oklahoma City, where it eventually landed safely.

By Victor Mather

A Southwest Airlines plane descended prematurely on Wednesday over Oklahoma City, startling residents miles from the airport, before regaining altitude and then landing safely.

After beginning a descent from 39,000 feet, the Boeing 737-800, flight No. 4069 from Las Vegas to Oklahoma City, was still nine miles short of the airport when it reached an altitude of about 525 feet, according to a report by The Associated Press that cited Flightradar24 data. The plane then ascended again to about 3,000 feet before landing successfully at its planned destination, Will Rogers World Airport, at 12:16 a.m. local time.

An automated warning was triggered by the low altitude, and an air traffic controller alerted the pilots, the Federal Aviation Administration said in a statement.

“Southwest 4069, low altitude alert. You good out there?” the controller can be heard saying in a recording from LiveATC.net provided to The Oklahoman newspaper .

The F.A.A. said it was investigating the incident.

The plane’s low point happened roughly over the city of Yukon, just west of Oklahoma City. Some people in the area said on social media that they were alarmed by the noise and low path of the jet.

“Southwest is following its robust Safety Management System and is in contact with the Federal Aviation Administration to understand and address any irregularities with the aircraft’s approach to the airport,” the airline said in a statement.

There is no indication that the incident was caused by any mechanical failure, but Boeing planes have been involved in several recent safety incidents.

Most notably, a door panel blew out of an Alaska Airlines 737 Max 9 jet in January, leading to the temporary grounding of some planes, a company plan to improve safety and an apology from the company’s chief executive, Dave Calhoun.

Last month, a Southwest Boeing 737 Max 8 en route from Phoenix to Oakland experienced what is known as a Dutch roll , a scenario in which the plane faces simultaneous side-to-side and rocking motions.

Victor Mather , who has been a reporter and editor at The Times for 25 years, covers sports and breaking news. More about Victor Mather

Boeing: A Company in Turmoil

Settlement Violation: The Justice Department is considering allowing Boeing to avoid criminal prosecution for violating the terms of a 2021 settlement related to problems with the company’s 737 Max 8 model that led to two deadly crashes in 2018 and 2019.

Senate Hearing: Confronted by families of those killed on two flights, Dave Calhoun, Boeing’s chief executive, apologized for “the grief that we have caused.”

Very Little Oversight: A top F.A.A. official said that the agency failed to adequately oversee Boeing and that it should have had better visibility into the plane manufacturer’s safety practices long before a door panel blew off a plane.

Is It Time for a New Plane?: Some analysts say building a new plane would help the company regain the ground it has lost to Airbus. But doing so would be difficult and expensive .

Plan To Fix Safety Issues: Boeing’s top executives delivered a plan to improve quality and safety to the F.A.A ., vowing to address systemic issues that have damaged the company’s reputation and put the manufacturer at the center of several federal investigations.

While Boeing’s regulatory woes grab headlines, the real battle is brewing closer to home: With its own union

On a Friday in early April, the happy hour crowd’s just getting its buzz at the Cactus Moon Saloon, a blue-collar mega sports bar situated in a strip mall in Everett, Wash. As “Big Bad John” and “Hot Rod Lincoln” blast over the TouchTunes jukebox, wisecracking waitresses dispense foaming pints drawn from a “beer tower” offering 20 varieties, from Modelo and IPA to local favorite Manny’s Pale Ale. Ringing the giant U-shaped room are pulsating neon logos hailing assorted liquors and beers interspersed among 31 TV screens displaying such fare as University of Evansville versus Indiana University baseball and the Wells Fargo golf tourney. Folks attired in sneakers, T-shirts, and baseball caps take aim at a choice of seven dartboards.

But the Cactus Moon isn’t just a watering hole—it’s a great forum for learning about what’s gone wrong at the Boeing Co. As a favorite hangout for retired and mainly boomer and Gen X workers from the planemaker’s nearby Everett plant, the place is a fount for up close and personal accounts of a once-fabled culture’s decline from the people who’ve lived it.

They called the old-timers “the gangsters,” says a genial Cactus habitué at the bar whom I’ll call “Freddie the Fastener.” Sipping a Bud Light, Freddie recounts that he spent 34 years at Boeing as a machinist on the 747 and 767 programs—his proud craft, operating the three-story-tall Gemcor machines that fasten the wing beams to the panels. Freddie saw his employer go from something akin to a family business with layers of oversight at every turn, to a place where pensioners saw their benefits slashed, and left in droves. The production gaffes that caused the infamous 737 Max door-plug blowout over Portland, Ore., on Jan. 5 didn’t surprise Freddie. “The workers around me kept getting younger and younger, but instead of giving them more supervision, Boeing kept cutting safeguards,” he says. “I told my bosses: ‘If you do this, you’re going to have problems.’ Their actions raised the risk of disasters like the one that just shocked the world.”

Today, Boeing is a colossus in crisis. Its myriad problems all arise from the long-hidden failings in its quality control regime that so scared Freddie in his last years at Everett, and that sundry whistleblowers have flagged since. For at least a decade, its management put speeding production to boost profits over sustaining the ironclad processes and procedures essential to building aircraft featuring the highest levels of reliability and safety. Says a top aerospace executive: “They focused on financial returns and not actively promoting safety.”

But while safety has dominated the headlines, there’s another vexing issue facing Boeing that threatens to explode this summer. On March 8, Boeing began bargaining its first full-scale agreement in 16 years with the International Association of Machinists and Aerospace Workers (IAM), the union that numbers 32,000 at Boeing and accounts for over half of the entire U.S. workforce in the commercial airplanes division. Put simply, this is America’s most important labor negotiation in decades.

Boeing is on its heels. The forces in the union’s corner are powerful, and have only grown more so as sundry quality issues plague the aerospace giant. The story of how the union in recent years battled Boeing over its removal of in-person inspections on the factory floor, finally taking its case to the Federal Aviation Administration, and how that conflict is shaping its current demands, is potentially central to Boeing’s future. And the contract negotiation’s outcome could well determine whether Boeing reaffirms its traditional identity and culture by agreeing to build its next clean-sheet plane in Washington’s Puget Sound, home to its giant Renton and Everett plants, or seeks lower-cost options in competing states.

Boeing vs. its union

In an interview with Fortune at his headquarters, on the second floor of a nondescript low-slung office building in a modest Seattle suburb, IAM District 751 president Jon Holden started by slamming the ultra-hardball tactics Boeing deployed in the past two negotiations. “In 2011, Boeing threatened to move 737 production somewhere else, like they’d just done by moving part of the 787 output to [North] Charleston,” he says. That contract was supposed to run from 2012 to 2016. “But it was just a year and 10 months later that they threaten to move the new 777X [then in development] to another state.” At the time, Boeing was tightening the vise by having an internal lobbyist fly around the country shopping for the best deals in Texas, Utah, and South Carolina.

Holden continues the history of hurt: “In 2013, they demanded that we extend the contract all the way until late 2024 in exchange for making the 777X in Everett. But this time, the sacrifice was giving up our defined pension plan and a massive medical care cost-shift to our members and stagnating wages for 10 years and nine months. That’s what started to turn our relationship so negative, their threats to take our livelihood away.” A Boeing spokesperson responded: “Over the last 10 years, our machinists’ pay growth has outpaced inflation every single year, even in the last few years when inflation was high.”

Holden now wants Boeing to agree to something it’s never consented to before: pledging to build an all-new aircraft in a specific place. (The 777X is a larger derivative of the 777.) “We believe it has to happen here,” he says. “I have to get that security piece, and it can’t be up to them at some point in the future to threaten us to move it somewhere else. This is our only opportunity, and the time is right now.” In addition? Wage increases totaling 40% over a three-year contract. The chief also reckons that the IAM deserves a seat on Boeing’s currently 13-member board.

An IAM team of 40 negotiators has formed half a dozen groups to bargain with their Boeing counterparts on all different aspects of the work rules and money issues. The first major day of reckoning is July 17, when IAM members will convene in T-Mobile Park (capacity: 50,000), home field to the Seattle Mariners, for a vote on authorizing management to call a strike if the two sides can’t reach an agreement before the contract expires. It’s getting close to crunch time: The contract deadline falls on Sept. 12, and marks one of the key dates in the annals of labor-management dealmaking. If membership votes yes on July 17, and the talks remain deadlocked at midnight on Sept. 12, the IAM leadership can launch a strike, a weapon it last unsheathed in 2008, emptying Boeing’s Seattle-area plants for nearly 60 days.

Holden says he’s got high hopes that the two sides can reach an agreement and avoid a strike. “We want Boeing to be profitable; we need a healthy Boeing,” he avows. But Holden has rallied his troops to endure a long walkout if that’s what it takes to secure the bulk of their agenda. For over two years, he’s been exhorting his members to save part of their salaries to tide them through an extended period sans paychecks.

It’s a theme the IAM head likes repeating: “We have to save Boeing from itself.” Besides new benefits that he believes would once again encourage longevity, Holden reckons that a big part of this rescue operation involves gaining authority the union’s never had before: a role in setting the manpower and oversight for Boeing’s quality-control–troubled operation. “We’re proposing that we have the right to negotiate provisions that go into the safety and quality of the planes,” he says.

CEO Dave Calhoun hasn’t commented on how an agreement might influence Boeing’s cost structure. A company spokesperson told Fortune : “Both parties want to reach an agreement without a strike, and we believe in a path that brings balance. It’s safe to say we’ll give outstanding pay and benefits.” The spokesperson added, “We’re very committed to Puget Sound, where we have five aircraft programs and 4,900 planes in backlog,” also noting that Boeing expects the IAM to advocate for a role in quality control.

To grasp why the IAM’s seeking these new powers, it’s crucial to examine the work mechanics perform; the crash- and pandemic-driven demographic upheaval in their ranks; and the war between the union and Boeing management over quality control that started in 2017, and remains only partially resolved.

Boeing’s union boasts a proud, militant heritage—and members still fume over their skewering on the last contract

The IAM dates from 1888, when 17 machinists gathered in an Atlanta railroad pit under cloak of darkness, to form a union. In the early days, members were called “boomers,” part skilled craftsmen, part vagabonds who followed the tracks from one boomtown to the next, laboring in shoe factories and foundries. Today, the IAM encompasses around 600,000 active or retired members in the U.S. and Canada, working in such industries as railroads and airlines, and besides Boeing, at such aerospace giants as RTX , Lockheed Martin , and NASA.

Boeing’s machinists still rank among the crème de la crème of America’s industrial workforce, given their skills in crafting the biggest and most complex products made in America. They are basically divided into two groups. The first are the workers who build the planes. They perform the riveting that joins the aircraft’s sections; attach the wings to its body deploying fasteners; put down floorboards; and install insulation blankets, passenger seats, and racks holding computer equipment. This isn’t high-volume automaking; assembling these wondrous flying machines requires lots of virtually artisanal workmanship. Boeing’s assembly lines feature low levels of automation; it’s all about the high-touch workmanship performed by mechanics.

The second group: quality assurance inspectors. It’s the QAs who ensure that the building crews are doing their jobs correctly. They perform in-person checks on everything from the torque applied to a nut to wiring connections to debris strewn in areas of the plane about to be closed up. The QAs are responsible for verifying that the parts and systems installed in the aircraft conform to the design laid out in the production certificate approved by the FAA, and that all the work is performed according to the processes and procedures described in Boeing’s quality manual, a document also approved by the aerospace watchdog. In-person inspections by highly trained and qualified personnel are required under the Code of Federal Regulations issued by the FAA.

A major breach over quality control dividing Boeing and the IAM surfaced in 2018. In November of that year, management presented the IAM with a PowerPoint outlining a sweeping revamp of the manufacturing system. The idea was to automate, simplify, and streamline traditional processes in the lean manufacturing mold. A few years earlier, Boeing had launched a similar regime at its non-union plant in North Charleston, and it was now coming to Renton and Everett. A central plank: empowering the mechanics building the planes to inspect their own work as they did their riveting, shimming, or fastening. For many jobs, the new regime would eliminate the long-standing checks on their finished work performed by quality assurance inspectors.

Hundreds of members packed the union halls in Renton, Everett, and Auburn to denounce the initiative. The resistance rallied under the banner, “It’s not okay to cut QA!” The rank and file especially resented that; according to IAM leadership, Boeing had already been nixing inspections in Renton during 2017 without informing the union. A program architect was Ernesto Gonzalez-Beltran, the newly hired VP of total quality, who had spent 24 years in automotive manufacturing positions at Ford and more recently Toyota .

In January of 2019, Boeing gave the program, called Quality Transformation, or QT, a splashy debut at the Everett facility. Gonzalez-Beltran hosted the acclaimed Seattle Times reporter Dominic Gates—who would go on to win a Pulitzer Prize for his coverage of the 2018 and 2019 Boeing 737 Max crashes—photographer in tow, on a tour to demonstrate how Boeing was deploying smart tools and digital technology to speed production while lowering defects. “By allowing inspectors to verify their own work, wait time is eliminated,” Gonzalez-Beltran explained. The smoother workflow would help mechanics get it right the first time. Gonzalez-Beltran asserted that the QAs’ inspections were “only 87% effective,” and predicted that the innovations would bring “radical improvement” in overall quality. “I’ve seen the future,” he declared, “because I’ve seen it in the auto industry,” adding that “when there are consistently stable processes, there is no value added from a second set of eyes.”

The program called for reassigning 900 of the 3,000 quality inspectors over the next two years to other jobs, such as finding the root causes where defects were most frequent. QT ended the in-person QA checks on the vast majority of shimming for all programs, the process of filling tiny gaps between sections of the plane with metal slivers often the width of a human hair; shimming reduces the stress the airframe encounters while in flight. Instead, the mechanics ferried data on the size of the gaps, the tools used, and other aspects of the job to the QAs, who no longer verified the work on-site and in person. The IAM also charges that Boeing removed QA inspections from “close tolerance” holes, where mechanics zap rivets to join different parts of the skin covering the primary structure, as well as many “functional tests,” final checks on major systems once the plane’s completed, including engines, hydraulics, flaps, and rudders. (Boeing says that it restored the close-tolerance-hole inspections in the 2019–20 time frame.)

According to the IAM, from 2017 to 2019 Boeing removed 3,200 inspections per plane on the 737 Max, lowering the total from 14,300 to around 11,000.

Holden denounced the plan, positing that it would cause lots of out of sequence work as planes moved down the line, and delay deliveries. “QT was quality suicide,” says one IAM member who fought the strategy. “It was just the Toyota guy’s plan to speed up production.”

To address these grievances, Boeing in April of 2019 agreed to allow an IAM committee to review all work “packages,” either in place or proposed, that removed inspections. If the IAM could show that the changes hurt quality, Boeing vowed that it would restore the eliminated QA checks, or cancel proposed packages. The IAM also won the right to bring objections directly to the FAA, without Boeing’s review. “When they just barreled forward, we turned to whistleblowing to the FAA,” says Holden. In Q3 and Q4 of 2020, IAM committee members filed four “Hotline” complaints to the FAA. They detailed 10 cases where Boeing had removed in-person QA inspections and replaced them either with sign-offs by machinists, or a system of random sampling.

In May 2021, the IAM secured a key ruling, called an enforcement investigative report (EIR). The FAA found that in all instances Boeing had eliminated the direct QA checks in violation of its rules, and, according to the IAM, the FAA effectively directed Boeing to reinstate the canceled inspections. Typical of the agency’s commentary: “The FAA found evidence that Boeing inappropriately assigned inspection authority to manufacturing personnel who did not have the appropriate training or certification.”

It appears that QT pretty much died in 2021 with the EIR ruling. Boeing never officially announced an end to the program, but by most evidence it backfired. According to whistleblower accounts, Boeing’s plants kept suffering from numerous quality issues, including defective parts that were mislabeled and actually installed in the finished planes; faulty firing mechanisms on many of the cylinders that deliver oxygen to face masks that fall from the plane’s ceiling in the event of an accident; and razor-short titanium slivers that lodged among the planes’ wire bundles, allegedly raising the risk of short circuits. (Boeing states that none of those issues affected safety, and all have been addressed.) Gonzalez-Beltran reportedly left in December of 2021. In January following the door-plug blowout, Boeing announced plans to greatly boost quality control oversight, and noted that it had already increased the number of QAs by 20% over the pre-COVID peak to around 3,600.

Meanwhile, aftershocks from the fatal Lion Air and Ethiopian Airlines 737 Max crashes, the latter in March of 2019, were whittling down an experienced workforce. That month, the FAA grounded all Max jets, a ban that lasted until December of 2020. Prior to the COVID outbreak, Boeing had moved 737 workers to other programs. Then the outbreak that hammered airline traffic by 96% caused big workforce reductions. Veteran machinists, no longer padding their pensions by staying longer, grabbed the rich retirement packages and departed en masse. All told, around 6,000 IAM members left, reducing their ranks from 2019 to 2021 by almost 20%, to the 27,000 range. As production rebounded starting in 2021, Boeing went on a hiring rampage, adding 3,500 machinists in 2023 alone. “We’re on this massive upswing, and it’s hard to get everyone up to speed,” says Holden. A Boeing spokesperson agrees, telling Fortune : “It’s a different world. We’ve lost a lot of institutional knowledge, and it’s especially acute in quality compliance. Getting this right will require much more training than in the past.”

During a media tour of the 737 plant in Renton on June 25, Boeing’s VP for quality stated that a “moving crew” of mechanics closed the door plug that ripped off over Portland that was notoriously missing four bolts needed to secure it in place. But she stressed that it was simply their job to “ensure that any open holes on the plane are covered,” and that the workers weren’t responsible for reinstalling the “retaining pins” that had been removed. The failure, she said, arose because “The plug was opened without the correct paperwork.” She did not specify who was responsible for supplying that documentation. It’s clear that the controls and oversight governing the work were inadequate. No evidence exists that QAs were informed about the replacement or inspected the work. In a letter to Congress, Jennifer Homendy, chair of the National Transportation Safety Board, stated that she had called Calhoun, asking for the names of people who had done the job, and that the CEO was unable to “provide that information, and maintained that Boeing had no record of that work being performed.”

Meanwhile, the FAA has demanded that Boeing submit a comprehensive new plan to revamp its quality and safety procedures so damaged by the exodus of seasoned personnel. On May 31, the planemaker submitted its blueprint to the agency. The 11-page “executive summary” outlines such reforms as adding new inspections at crucial points in the production process, and extensive increases in time and spending devoted to employee training. High on the agenda: improving its internal reporting system for employees to ensure they can report quality gaffes from the factory floor anonymously, and without fear of retaliation.

Boeing is also moving to assert much stronger control over its manufacturing chain, after decades of extensive outsourcing. It’s announced plans to purchase Spirit AeroSystems, manufacturer of its 737 fuselages that have been arriving in Renton requiring major repairs, and has already dispatched many of its own inspectors to Spirit’s plant in Wichita. The safety plan includes an initiative to end “traveled,” or out-of-sequence, work where machinists don’t perform jobs at their regular station and rush to install parts or systems further down the assembly line. Top management seldom mentioned the problem of traveled work in the past in earnings calls or presentations before the Jan. 5 disaster. Suddenly, it’s a big deal. Likewise, the program submitted to the FAA pledges to strengthen the systems for managing aircraft parts.

One outcome that’s tough to predict: whether Boeing agrees to build the Max’s successor in Puget Sound—once again, a pledge it’s never given before on an all-new plane. The argument for dedicating its future to this region rich in seasoned personnel and aerospace culture—just consider how Boeing lures generation after generation of the same families—is a persuasive one. The giant upheaval from COVID that forced so many Americans to change locales and industries makes the strong concentration of airplane-production skills still found in Puget Sound more valuable than ever. That decision may signify that Boeing is rededicating itself to the culture that bred veterans like Freddie the Fastener.

At the Cactus Moon Saloon, Freddie—between peeling 50-cent pull tabs and getting enough matches to win a free Bud Light—is waxing nostalgic. “In the old days, it was such a great place to work. It seemed like everyone had been there for 10 or 20 or 30 years, and had a wife or kids at Boeing,” he recalled. As for the inspectors? “They were officious, but they were necessary. I didn’t want to hear about the wings I was fastening coming loose on the planes!” For Freddie, job one for Boeing is restoring that culture of loyalty and longevity. In recent years, the workers mainly got it right, and the C-suite mostly got it wrong. This historic contract, coupled with Boeing’s choice of a new CEO, will help determine if the legendary name gets its wings level by restoring the practices that made it great, or continues the most shocking and sudden descent in modern corporate history.

Latest in Finance

A loophole in U.S. tariffs on Chinese EVs has allowed a flood of golf cart imports, and domestic producers are asking Biden for help

The owner of Redbox DVD kiosks just filed for bankruptcy, saying results ‘failed to meet management’s expectations’

The housing market’s lock-in effect could last into the next decade as mortgage rates stay high even with Fed cuts, BofA says

Nvidia will produce such a massive ‘cash gusher’ that it will have to buy back more stock because all that money has nowhere else to go, analyst says

Amazon is reviewing reports that Perplexity AI is scraping online news content without approval

JPMorgan, BofA and other top banks shower investors with fatter dividends after easily passing the Fed’s stress tests

Most popular.

Patagonia became famous for letting staff cut out early to chase waves—now it’s asking dozens of employees to relocate or leave because it’s 300% overstaffed

Warren Buffett warns Gates Foundation there is no guarantee his support of the charity will continue once he’s gone: ‘No money coming after my death’

‘Barbie’ star Margot Robbie says selling her own alcohol brand was easier than selling her $1.4 billion movie idea

4 expert-recommended supplements to boost your energy

LVMH’s Bernard Arnault got a letter from 93-year-old Warren Buffett saying he was making a mistake by upping his retirement age to only 80

IMAGES

VIDEO

COMMENTS

Join me on this detailed tour / documentary around a QANTAS Boeing 747-400 Jumbo Jet, VH-OJA, on display at the HARS Aviation Museum in Wollongong, Australia...

Lufthansa Airlines Boeing 747-8 cabin tour. This aircraft has 8 First class, 80 business class, 32 premium economy, & 244 economy seats. Sorry this one is a ...

747 Tour. Fly the iconic airliner on busy cargo routes and select passenger services. Updated for 2022. This is a tour of 42,627 nm (78,945 km) divided into fourteen legs. To complete this tour, you will need to fly at least one route of each of the legs listed below. You will need to fly all legs using one of the aircraft types listed below.

The plane is open 11 a.m. - 3 p.m. on days the Museum is open and is included with the cost of Museum admission. Service. Ship 630 1 was the first 747-400 built by the Boeing Aircraft Company. It was registered by Boeing as N401PW, and first flew on April 29, 1988. ... This tour of the 747 Experience was created for Delta's BIG THANK YOU to ...

The cockpit of a British Airways Boeing 747-400 is a beautifully complex place where a handful of analog gauges live side-by-side with digital displays. Among the vast array of system switches and ...

Delta Airlines - On Board Cabin Tour. New 747-400 aircraft, redesigned from nose to tail with state of the art amenities and world-class comforts for the bus...

747 Tour Dates: 25 - 25 Oct, 2022; Email: [email protected]; How to find us: After you buy your admission ticket in the Museum lobby, meet under the 747 plane at 1 pm. Tour lasts about 45 minutes. Phone: 404-715-7886

The 747 Experience. Up Close and Personal with "The Queen of the Skies". The Delta Flight Museum offers visitors the opportunity to explore the first 747-400 ever built, Delta's Ship 6301. The exhibition provides an in-depth look into one of the most iconic aircraft to ever fly. While visiting The 747 Experience families and groups will.

The 'Landor' Boeing 747 is being given a new lease of life at Dunsfold Park Aerodrome in Surrey. On 26th June, you have your first chance to visit the aircraft. To quote the website: "We are please to offer you the first ever opportunity to get onboard and to photograph a British Airways 747 since retirement. Get up close and personal ...

The Delta Flight Museum put up the first Boeing 747-400 ever built - Ship 6301 - on display at Delta's Atlanta headquarters in Hapeville, Georgia, in 2017. Visitors can walk through the aircraft, visit the upper deck, and even walk out on the wing. The decades-long history of the aircraft is presented with an up-close experience of the mighty jet.

Each tour is an 80-minute guided experience with a front row view of current airplane production, the Everett site's history and the central role it plays in the future of commercial aviation. Pro-Tip: Tickets sell out quickly. We recommend booking tickets in advance, either online or through the Call Center: +1 (800) 464-1476.

Boeing 747-121. The growing worldwide demand for air travel during the 1960s led Boeing to launch the 747, the first wide-body jet. Developing what was then the world's largest passenger aircraft was a formidable undertaking, requiring the company to risk much of its net worth. But the gamble paid off - over 1,500 units have been produced.

Regular Tours. Since March 2022, Negus has been open to the public for self-guided tours most Wednesdays and Saturdays, subject to availability. Follow the link below to book tour tickets. Dates are released a few weeks in advance. Tours will not be running during November and December due to the Immersive Theatrical Christmas Experience hosted ...

You even get to see the secret crew cabin. Aviation enthusiasts always love to know more details about iconic planes — and today we will get to take a detailed tour of the Boeing 747 and see parts of the plane that passengers don't see. Let's join Paul Stewart on his tour around his series of tours around aviation icons.

Alberto Pinto's 747 BBJ ... A nose to tail tour Starting at the nose of the jet, underneath the cockpit sits the master bedroom. This location, well away from the hum of the engines, makes for a tranquil and relaxing space. ... At the rear of the plane, the owner can accommodate plenty of extra staff and entourage in the business class-style ...

This allows those who haven't stepped foot inside a freighter aircraft an intricate look at how and where cargo is loaded and positioned on our aircraft. Various time-lapse videos demonstrate how precise and calculated it is to load large and heavy pieces of cargo on board. The B747-400F Aircraft virtual tour also includes a look at the upper ...

747 Tour Dates: 08 - 08 Nov, 2022; Email: [email protected]; How to find us: After you buy your admission ticket in the Museum lobby, meet under the 747 plane at 1 pm. Tour lasts about 45 minutes. Phone: 404-715-7886

Boeing 747-8. Seat maps Boeing B747-8. Sample illustration B747-8 (8 First / 80 Business / 32 Premium Economy / 244 Economy) Main deck. Upper deck. Seat maps of the Boeing B747-8 to download. PDF download seat map B747-8 main deck and upper deck (8F / 80C / 32E / 244M) Technical data. Length: 76.30 m: Wingspan: 68.40 m:

Aviation enthusiasts get an exclusive Boeing factory tour where some of the world's biggest, most advanced airliners are made, including 747, 777 and 787.

Jun 23, 2022, 4:55 AM PDT. Boeing 747 Factory Tour. Seattle Times. Boeing is building the last three 747 aircraft it will ever produce. All three planes will be delivered to cargo carrier Atlas ...

Iron Maiden's iconic 'Ed Force One' planes, a Boeing 747 and Boeing 757, were used for their world tours and piloted by lead vocalist Bruce Dickinson. The Boeing 747, known by the registration TF-AAK, is now owned by Air Atlanta Icelandic. The first 'Ed Force One' Boeing 757, registered as G-OJIB, is now employed by FedEx Express, while the ...

An Air Force spokesperson told the military website Breaking Defense that the first flight of the next-generation Boeing 747-8i — set to replace the old 747-200Bs first put into service in the ...

Want an overview of the Museum's 747 Experience? Take a tour! On the 2nd and 4th Tuesday of each month, we offer a free guided tour with normal ... Meet up under the plane to start the tour. DC-3 Ship 41 Tour. Jun 04, 2024. Paper Planes & Pops. Jul 14, 2024. Paper Planes & Pops. Jun 23, 2024. Surplus Sale - Save the date. Jun 14, 2024. Movie ...

Corenswet was seen dressed in a black cape strolling along the street and checking out the set, which is strewn with prop rubble and wrecked cars, and appears to be ready for shooting an explosive ...

The plane's low point happened roughly over the city of Yukon, just west of Oklahoma City. Some people in the area said on social media that they were alarmed by the noise and low path of the jet.

Sipping a Bud Light, Freddie recounts that he spent 34 years at Boeing as a machinist on the 747 and 767 programs—his proud craft, operating the three-story-tall Gemcor machines that fasten the ...