Voyager® Commercial Heating and Cooling Rooftop Units

Voyager® 2 – 12.5 – 25 Tons & Voyager® 3 27.5 – 50 Tons

Key Features:

- Available in gas/electric, electric/electric & heat pump only for Voyager 2.

- Dependable MERV filtration that removes contaminants as small as 0.3 microns.

- Fast delivery to keep projects on track and sites up and running.

- Energy-efficient performance lowers costs without sacrificing comfort.

- Engineered for performance and durability.

- Connected-ready to optimize HVAC performance.

- Fully customizable.

- Designed-in features simplify installation and service.

- Trane quality guarantee.

- Financing available.

Request a Quick Quote

Ultra-energy efficient comfort.

Guaranteed Quality You Can Count On

Trane’s Voyager 2 & Voyager 3 rooftop units offer sustainable HVAC solutions backed by an outstanding warranty:

• ASHRAE 90.1 and Energy Star compliant.

• Optional Trane eFlex™ variable-speed compressors and fans deliver ultra-high efficiency .

• Variable air volume (VAV) options service single- and multi-zone applications.

• 10 years on the stainless steel heat exchanger.

• 5 years parts only on the compressor.

• 5 years on low-leak economizer.

• 1 year on all standard parts

• Extended warranty options for additional peace of mind.

The Voyager rooftop unit line features:

Choose from Voyager 2 or Voyager 3 models to meet the needs of a broad range of small, medium to large commercial buildings.

- High-efficiency filtration removes contaminant particles as small as 0.3 microns with MERV 8, MERV 13, and up to MERV 14 filters (with Voyager 3).

- Hot gas reheat cycles heat energy from the compressor to reduce indoor air humidity.

- Unique coil design uses less refrigerant.

- All-aluminum microchannel (MCHE) condenser coils provide extra durability.

- Foil-faced insulation edges prevent fibers from entering the airstream and clogging filters.

- Coating options to protect against corrosion.

- Easy chemical-free cleaning.

Performance and Durability You Can Rely On

12.5 – 25 Tons

Cooling, Electric/Electric & Heat Pumps.

- The lowest total cost of ownership = low installation & maintenance costs.

- High-efficiency options with Up to 20.1 IEER with eFlex technology cooling, gas/electric models.

- Fastest delivery times – get it within 2 weeks.

- Design customization with a wide variety of factory-installed options to meet the needs of unique light commercial applications.

- Single & multi-space VAV options.

- Dual compressors provide outstanding humidity control, light load cooling, and system backup.

- Dependable performance with ReliaTel controls, computer-aided run testing & 3-D scroll compressors.

- Color-coded and numbered wiring (Voyager 2) for easier installation.

Designed for maximum performance & efficiency in larger buildings.

27.5 – 50 Tons

With Voyager 3 a variety of standard and optional features offer customized HVAC solutions for larger commercial buildings:

Same footprint designed to match legacy models for plug and play replacement.

- Ready to go out of the box design.

- Optional Trane eStage™ compressors deliver increased full and part load efficiencies = 5 – 15% higher full load efficiencies & 15 – 25% higher part load efficiencies vs standard units.

- Trane® Air-Fi Wireless connectivity for hassle-free installations.

- Touchscreen Human Interface – easy access to manage & monitor performance.

- Modulating gas heat & modulating hot gas reheat.

- Ultra-low leak economizer.

- Monitor outside airflow with Traq.

- Microchannel condenser coil for exceptional heat transfer.

- IBC & OSHPD seismic compliance.

Voyager is Not a One Size Fits All – Multiple Custom Options Available

Dozens of factory-installed options include:

- Optional Trane eStage™ compressors deliver increased full and part load efficiencies on Voyager 3.

- Trane® Air-Fi Wireless connectivity.

- CO2 sensor wiring.

- Fault detection diagnostics.

- High-efficiency motors and filtration

- Multiple-zone VAV controls and many more.

For a hassle-free commercial heating repair or replacement, commercial air conditioning repair or replacement, or an industrial ac repair or replacement estimate, from 3-ton rooftop ac units and 5-ton rooftop ac units to 3-25+ zoned rooftop systems, contact Comfort Solutions Heating and Cooling today at 763-565-2121 , your local commercial HVAC expert. Plus, we provide financing options through Trane® Technologies Financial Services. In addition to rooftop repair and replacement, we specialize in split systems furnace and air conditioners, ductless splits, commercial make-up air units, infrared heaters, unit heaters, and building controls and exhaust fans.

- Trane Manuals

- Air Conditioner

- Voyager Commercial

- Installation, operation and maintenance manual

Trane Voyager Commercial Installation, Operation And Maintenance Manual

- Installation & operation manual (152 pages)

- Manual (93 pages)

- page of 156 Go / 156

Table of Contents

- Troubleshooting

Model Number Description

- 60 Hz Description

- 50 Hz Description

General Information

- About the Unit

- Exterior Inspection

Unit Dimensions and Weights

- Recommended Clearances

- Horizontal Ductwork

- Unit Dimensions

- Unit Rigging and Placement

Pre-Installation

- Downflow/Upflow Models

- Field Installed Control Wiring

- Gas Heat Requirements

Installation General Requirements

- Condensate Drain Connection

- Condensate Overflow Switch

- O/A Sensor & Tubing Installation

- Units with Statitrac

Installation Electrical

- Disconnect Switch External Handle

- (Factory Mounted Option)

- Main Power Wiring

- Through-The-Base Electrical

- Electrical Service Sizing Data

- Electrical Wire Sizing and Protection

- Calculation #1 - TC*, YC* - 27.5 to

- Calculation #2 - TE* - 27.5 to 50 Ton

- Disconnect Switch Sizing (DSS)

- Low Voltage Wiring

- Control Power Transformer

- Field Installed AC Control Wiring

- Field Installed DC Control Wiring

- Constant Volume and Single Zone VAV Control Options

- Variable Air Volume (Non-SZ VAV)

- Control Options

- VAV Controls Available from the Factory for Field Installation

- Constant Volume or VAV

- Installation

- Space Temperature Averaging

Installation Piping

- General Requirements

- Connecting the Gas Supply Line to the Furnace Gas Train

Furnace Gas Train

- ECA/RTEM - Economizer Actuator

- Reliatel Economizer Module

- EBA - Exhaust Blade Actuator

- RTAM - Reliatel Air Handler Module

- (Standard with Traditional VAV)

- Reliatel Ventilation Module

- Reliatel Dehumidification Module

- Conventional Thermostat Connections

- TCI - Trane Communication Interface

- LCI - Lontalk® Communication

- Interface (Optional)

- BCI - Bacnet® Communication

- WCI - Trane Air-Fi™ Wireless Comm Interface (Optional)

- Microelectronic Control

- Modulating Power Exhaust

- Mechanical Cooling Without an Economizer (CV and SZ VAV)

- Zone Temperature - Occupied Cooling (CV and SZVAV)

- Zone Temperature - Occupied Heating (CV and SZVAV)

- Supply Fan (CV and SZ VAV)

- Supply Air Tempering

Variable Air Volume Applications

- Supply Fan Output Control

- Minimum Supply Fan Output

- Supply Fan Mode Operation

- Setpoint Arbitration

- Units Configured with the Outside Air Measurement (Traq) Option

- Calibration

- Ventilation Control

- Space Pressure Control

- Traq Overrides and Special

- Considerations

- Supply Air Temperature Control - Heating and Cooling

- Supply Air Temperature Control - Occupied Cooling and Heating

- Supply Air Temperature Control with

- An Economizer

- VHR Relay Output

- Zone Temperature Control Without a

- Night Setback Panel or ICS

- Unoccupied Cooling

- Unoccupied Heating

Applications (Single Zone or

- Supply Duct Static Pressure

- Supply Air Temperature Reset

- VAV Supply Air Tempering

Constant Volume or Variable Air Volume

Traditional).

- Cooling (CV or SZ VAV Only)

- Gas Heat Control

- Electric Heat Control

- Clogged Filter Option

- Ventilation Override

- Emergency Stop

- Phase Monitor

- Low Pressure Control

- High Pressure Cutout and Temperature Discharge Limit

- Power Exhaust Control

- Lead/Lag Control

- Coil Frost Protection

- Modulating Hot Gas Reheat Frost

- Switch (Optional)

- VFD Programming Parameters

Preparing the Unit for Operation

- Electrical Phasing

- Voltage Supply and Voltage

Starting the Unit

- Service Test Switch Location

- Verifying Proper Fan Rotation

- Verifying Proper Air Flow (CFM) - CV

- Or Vfd's

- Exhaust Fan Operation

Economizer Damper Adjustment

- Economizer (O/A) Dampers

- Models with Ultra-Low Leak

- Economizers

- Manual Outside Air Damper

Starting the Compressor

- Starting 27.5 to 35 Ton Standard

- Efficiency Units

- Starting 40 to 50 Ton Standard Efficiency VAV Units

- Starting 27.5-50 Tons High Efficiency

- Units and 40-50 Tons Standard

- Line Weights

- Compressor Oil

- Charging by Subcooling

- Measuring Subcooling

- Gas Heat Units

- Electric Heat Units

- For Constant Volume Units

- For Variable Air Volume Units

- For Single Zone Variable Air Volume

Sequence of Operation

- Mechanical Cooling Sequence of

- Units Without an Economizer

- Economizer Operation Based on Dry

- Economizer Operation Based on Reference Enthalpy

- Economizer Operation Based on Comparative Enthalpy

- Economizers with Traq

- Modulating Hot Gas Reheat Sequence of

- Sensible Cooling or Heating Control

- Overrides Hot Gas Reheat

- Constant Volume (CV) Unit Fan

- Variable Air Volume (VAV) Unit Fan

- Ignition Control Module

- High Temperature Limit Operation

- And Location

- Constant Volume (CV)

- Variable Air Volume (VAV)

Zone VAV) Sequence of Operation

- Occupied Cooling Operation

- Economizer Cooling

- Compressor Cooling

- Occupied Heating Operation

- Staged Heating Operation

- Modulating Heat Operation with

- SZVAV Heating

- Unoccupied Cooling and Heating

- Modulating Hot Gas Reheat

Operation (Reliatel Control)

- Low Pressure Control (LPC) Sequence of Operation (Reliatel Control)

- High Pressure Control and Temperature Discharge Limit (Reliatel Control)

Discharge Limit (Reliatel Control)

Maintenance.

- Fan Belt Adjustment

- Cooling Season

- Heating Season

- Refrigerant Coils

- Microchannel Condenser Coil Repair

- And Replacement

- Final Process

- Fall Restraint

- Refrigerant Evacuation and Charging

- Charge Storage

- Precision Suction Restrictor

Diagnostics

- System Status / Diagnostics Checkout

- Diagnostics (VAV Only)

- Resetting Cooling and Ignition

- Zone Temperature Sensor (ZSM)

- Service Indicator

Economizer Actuator (ECA/RTEM) Test

- Economizer Fault Detection and Diagnostics

- Verify Economizer Status by

- Economizer Actuator

- Test 1: Testing the Variable Frequency Drive (VFD) Output

- Test 2: Testing the Static Pressure Transducer (SPT) Input

- Test 3: Testing the VAV Setpoint

- Potentiometers

- Test 4: Testing the VFD

- Test 2: Testing the VFD

- Compressor-Blink Codes

- TR-200 VFD Programming

Unit Wiring Diagram Numbers

And largerand related, warranty and liability clause.

- Commercial Equipment - 20 Tons

- Accessories

Advertisement

Quick Links

- 1 Model Number Description

- 2 60 Hz Description

- 3 Low Voltage Wiring

- 4 Unit Wiring Diagram Numbers

- Download this manual

Related Manuals for Trane Voyager Commercial

Summary of Contents for Trane Voyager Commercial

- Page 1 Installation, Operation, and Maintenance Voyager™ ™ Commercial Packaged Rooftop Air Conditioners with ReliaTel™ Controls and eStage™ 27.5 to 50 Tons - 60 Hz 22.9 to 41.7 Tons (81-148 kW) - 50 Hz “B” and later design sequence 6 6 0 0 H H z z / / 3 3 p p h h a a s s e e : TC*, TE*, YC*330B, 360B, 420B, 480B, 600B (60 Hz/3 phase) 5 5 0 0 H H z z / / 3 3 p p h h a a s s e e : TC*, TE*,...

- Page 2 A A L L W W A A Y Y S S r r e e f f e e r r t t o o a a p p p p r r o o p p r r i i a a t t e e S S a a f f e e t t y y D D a a t t a a impact to the environment. Trane advocates the...

- Page 3 . . This document and the information in it are the property of Trane, and may not be used or reproduced • •...

Page 4: Table Of Contents

- Page 5 Interface (Optional)....44 Night Setback Panel or ICS - WCI - Trane Air-Fi™ Wireless Comm Unoccupied Cooling....57 Interface (Optional).

- Page 6 T T a a b b l l e e o o f f C C o o n n t t e e n n t t s s Power Exhaust Control Final Unit Checkout ..... 106 (Tracking) .

- Page 7 T T a a b b l l e e o o f f C C o o n n t t e e n n t t s s Modulating Heat Operation with System Status / Diagnostics Checkout SZVAV Heating ..... 113 Procedure (DC Voltmeter Unoccupied Cooling and Heating Required) .

Page 8: Model Number Description

- Page 9 E = Field-Powered 15A GFI Convenience Outlet Digit 33 — Human Interface Digit 22 5 = Touchscreen Human Interface, 5inch F = Trane Communication Interface (TCI) Model Number Notes Digit 23 Notes: G = Ventilation Override All voltages are across the line starting only.

Page 10: 50 Hz Description

- Page 11 Digit 22 The service digit for each model number contains 33 digits; all 33 digits must be F = Trane Communication Interface (TCI) referenced. Ventilation override exhaust mode is not Digit 23 available for the exhaust fan with fresh air tracking power exhaust.

Page 12: General Information

Page 13: unit dimensions and weights, page 14: unit dimensions.

- Page 15 U U n n i i t t D D i i m m e e n n s s i i o o n n s s a a n n d d W W e e i i g g h h t t s s Figure 3.

- Page 16 U U n n i i t t D D i i m m e e n n s s i i o o n n s s a a n n d d W W e e i i g g h h t t s s Figure 5.

- Page 17 U U n n i i t t D D i i m m e e n n s s i i o o n n s s a a n n d d W W e e i i g g h h t t s s Figure 7.

- Page 18 U U n n i i t t D D i i m m e e n n s s i i o o n n s s a a n n d d W W e e i i g g h h t t s s Figure 9.

Page 19: Unit Rigging And Placement

- Page 20 2189.5 Note: Weights shown represent approximate operating weights and have a ±10% accuracy. To calculate weight for a specific unit configuration, utilize TOPSS™ or contact the local Trane® sales representative. ACTUAL WEIGHTS ARE STAMPED ON THE UNIT NAMEPLATE. Table 5. Point loading average weight— lbs./kg...

- Page 21 U U n n i i t t D D i i m m e e n n s s i i o o n n s s a a n n d d W W e e i i g g h h t t s s Table 6.

Page 22: Pre-Installation

Page 23: installation general requirements, page 24: units with statitrac.

- Page 25 I I n n s s t t a a l l l l a a t t i i o o n n G G e e n n e e r r a a l l R R e e q q u u i i r r e e m m e e n n t t s s Figure 18.

Page 26: Installation Electrical

- Page 27 I I n n s s t t a a l l l l a a t t i i o o n n E E l l e e c c t t r r i i c c a a l l •...

Page 28: Through-The-Base Electrical

- Page 29 I I n n s s t t a a l l l l a a t t i i o o n n E E l l e e c c t t r r i i c c a a l l Table 8.

- Page 30 I I n n s s t t a a l l l l a a t t i i o o n n E E l l e e c c t t r r i i c c a a l l Table 11.

Page 31: Electrical Wire Sizing And Protection

Page 32: disconnect switch sizing (dss), page 33: field installed dc control wiring.

- Page 34 I I n n s s t t a a l l l l a a t t i i o o n n E E l l e e c c t t r r i i c c a a l l •...

- Page 35 I I n n s s t t a a l l l l a a t t i i o o n n E E l l e e c c t t r r i i c c a a l l Figure 22.

Page 36: Remote Panels And Sensors

Page 37: vav controls available from the factory for field installation.

- Page 38 I I n n s s t t a a l l l l a a t t i i o o n n E E l l e e c c t t r r i i c c a a l l Figure 30.

Page 39: Space Temperature Averaging

Page 40: installation piping.

- Page 41 I I n n s s t t a a l l l l a a t t i i o o n n P P i i p p i i n n g g Table 19. Specific gravity multiplier Table 19.

Page 42: Startup

Page 43: reliatel ventilation module, page 44: reliatel dehumidification module, page 45: microelectronic control, page 46: modulating power exhaust, page 47: zone temperature - occupied cooling (cv and szvav), page 48: variable air volume applications, page 49: supply fan mode operation, page 50: units configured with the outside air measurement (traq) option, page 51: calibration.

- Page 52 S S t t a a r r t t u u p p Table 29. Design minimum OA flow setpoint Table 29. Design minimum OA flow setpoint (continued) (continued) Design Min OA Flow DCV Min OA Flow Voltage Design Min OA Flow DCV Min OA Flow Voltage Setpoint (R130)

Page 53: Ventilation Control

- Page 54 S S t t a a r r t t u u p p Figure 41. SZVAV DCV with OA CFM Figure 42. Minimum outside air CFM setpoint compensation Design @ Minimum Fan Speed (RTVM R130) Posi on Setpoints Corresponds to Design CO2 (DCV UL) Setpoint Design @ Middle Fan Speed (RTVM R136)

Page 55: Space Pressure Control

Page 56: traq overrides and special, page 57: variable air volume applications, page 58: supply duct static pressure, page 59: cooling (cv or sz vav only), page 60: electric heat control, page 61: control, page 62: power exhaust control, page 63: switch (optional).

- Page 64 S S t t a a r r t t u u p p Table 38. Condenser fan/compressor sequence - std efficiency (continued) Compressor Staging Sequence Condenser Fan Output O/A Temp. (°F) Unit Size (Ton) Step 1 Step2 Step 3 Output A Output B Fans “Off”...

- Page 65 S S t t a a r r t t u u p p Table 39. Condenser fan/compressor sequence - high efficiency 27.5-35 Ton High Efficiency Compressor Stage 1 Compressor Stage 2 Ambient Ambient # Cond # Cond Fan #1 Fan #2 Fan #3 Fan #1...

Page 66: Preparing The Unit For Operation

Page 67: voltage supply and voltage, page 68: service test switch location.

- Page 69 S S t t a a r r t t u u p p Table 41. Test mode states for traditional VAV units with modulating hot gas reheat and staged heat COOL TEST COMP PUMP- COMP COMP HEAT HEAT VAL- HEAT STEP MODE...

- Page 70 S S t t a a r r t t u u p p Table 42. Test mode states for CV units with modulating hot gas reheat and staged heat COOL TEST COMP COMP COMP HEAT HEAT VAL- HEAT STEP MODE ECON PUMPOUT...

- Page 71 S S t t a a r r t t u u p p Table 43. Test mode states for SZ VAV units with modulating hot gas reheat and staged heat COOL TEST COMP PUMP- COMP COMP HEAT HEAT VAL- HEAT STEP MODE...

- Page 72 S S t t a a r r t t u u p p Table 44. Test mode states for traditional VAV units with modulating hot gas reheat and modulating heat COOL TEST COMP HEAT PUMP- COMP COMP VAL- HEAT STEP MODE COMMAND...

- Page 73 S S t t a a r r t t u u p p Table 45. Test mode states for CV units with modulating hot gas reheat and modulating heat TEST COMP COMP COMP HEAT PUMP- COOL HEAT STEP MODE ECON OUTPUT VALVE...

Page 74: Verifying Proper Fan Rotation

Page 75: verifying proper air flow (cfm) - cv.

- Page 76 S S t t a a r r t t u u p p Figure 51. Supply fan performance curves 40 and 50 ton — 60Hz Figure 52. Supply fan performance — 22.9-29.2 tons — 50Hz Supply Fan Performance (996) (872) (747) (623)

- Page 77 S S t t a a r r t t u u p p Figure 53. Supply fan performance — 33.3 and 41.7 ton (IP) — 50Hz (1245) (996) (747) (498) (249) (0.0) 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000...

- Page 78 S S t t a a r r t t u u p p Table 47. TC*/YC*300–600 MBH economizer (R/A) Table 47. TC*/YC*300–600 MBH economizer (R/A) damper pressure drop – 60Hz damper pressure drop – 60Hz (continued) Unit Capacity Airflow (CFM) Pressure Drop (iwc) Unit Capacity Airflow (CFM) Pressure Drop (iwc) 8000...

- Page 79 S S t t a a r r t t u u p p Table 48. Supply air fan drive selections — 60 Hz 7.5 HP 10 HP 15 HP 20 HP Nominal Tons Drive No. Drive No. Drive No. Drive No.

- Page 80 S S t t a a r r t t u u p p Table 49. Component static pressure drops (in. W.G.) — 60Hz Heating System Filters Standard High MERV Efficiency Efficiency Throw- Hot Gas MERV 8 High Eff Gas Heat Electric Heat 14 High Nom.

- Page 81 S S t t a a r r t t u u p p Table 50. Component static pressure drops in. W.G (I-P) — 50Hz (continued) Heating System Filters Standard High MERV Efficiency Efficiency Throw- Hot Gas MERV 8 High Eff Gas Heat Electric Heat 14 High...

- Page 82 S S t t a a r r t t u u p p Table 51. Component static pressure drops Pa (SI) — 50 Hz (continued) Heating System Standard Filters Nom. Std Efficiency ID Throw- MERV 14 L/s Std Econo- MERV 8 High Eff Gas Heat Electric Heat...

Page 83: Exhaust Fan Operation

Page 84: economizer damper adjustment.

- Page 85 S S t t a a r r t t u u p p duct static pressures and over pressurization of the Table 57. 27.5 - 35 Ton downflow economizer (O/A) damper static pressure setup (continued) space when the unit is operating in the “economizer” mode.

Page 86: Models With Ultra-Low Leak

- Page 87 S S t t a a r r t t u u p p switch is set back to its original default position - Y Figure 62. Actuator auto-scaling feature details = 0 - same direction as spring return. (See Figure 62, p.

Page 88: Manual Outside Air Damper

Page 89: starting the compressor, page 90: starting 40 to 50 ton standard efficiency vav units, page 91: compressor oil.

- Page 92 S S t t a a r r t t u u p p motor burnout. If the oil is black and contains metal Refer to the refrigeration system in the maintenance flakes, a mechanical failure has occurred. This section for details on testing and replacing oil. symptom is often accompanied by a high compressor amperage draw.

- Page 93 S S t t a a r r t t u u p p Figure 74. 35 Ton operating pressure — standard efficiency (60 Hz) Figure 75. 40 Ton dual circuit operating pressure, Cir #1 — standard efficiency VAV (60 Hz) RT-SVX34R-EN...

- Page 94 S S t t a a r r t t u u p p Figure 76. 40 Ton dual circuit operating pressure Cir #2 — standard efficiency VAV (60 Hz) Figure 77. 40 Ton operating pressure — standard efficiency CV (60 Hz) 120F OD Ambient 115F OD Ambient 105F OD Ambient...

- Page 95 S S t t a a r r t t u u p p Figure 78. 50 Ton dual circuit operating pressure Cir #1 — standard efficiency VAV (60 Hz) Figure 79. 50 Ton dual circuit operating pressure Cir #2 — standard efficiency VAV (60 Hz) RT-SVX34R-EN...

- Page 96 S S t t a a r r t t u u p p Figure 80. 27.5 Ton operating pressure — high efficiency (60 Hz) Figure 81. 30 Ton operating pressure — high efficiency (60 Hz) RT-SVX34R-EN...

- Page 97 S S t t a a r r t t u u p p Figure 82. 35 Ton operating pressure — high efficiency (60 Hz) Figure 83. 40 Ton operating pressure — high efficiency (60 Hz) RT-SVX34R-EN...

- Page 98 S S t t a a r r t t u u p p Figure 84. 50 Ton operating pressure — high efficiency and standard efficiency CV (60 Hz) Figure 85. 22.9 Ton operating pressure — standard efficiency (50 Hz) RT-SVX34R-EN...

- Page 99 S S t t a a r r t t u u p p Figure 86. 25.4 Ton operating pressure — standard efficiency (50 Hz) Figure 87. 29.2 Ton operating pressures — standard efficiency (50 Hz) RT-SVX34R-EN...

- Page 100 S S t t a a r r t t u u p p Figure 88. 33.3 Ton operating pressure — standard efficiency CV (50 Hz) 120F OD Ambient 115F OD Ambient 105F OD Ambient 95F OD Ambient 85F OD Ambient 75F OD Ambient 65F OD Ambient 55F OD Ambient...

- Page 101 S S t t a a r r t t u u p p Figure 90. 33.3 Ton dual circuit operating pressure, circuit #2 — standard efficiency VAV (50 Hz) Figure 91. 41.7 Ton dual circuit operating pressure, circuit #1 — standard efficiency VAV (50 Hz) RT-SVX34R-EN...

- Page 102 S S t t a a r r t t u u p p Figure 92. 41.7 Ton dual circuit operating pressure, circuit #2 — standard efficiency VAV (50 Hz) Figure 93. 22.9 Ton operating pressure — high efficiency (50 Hz) RT-SVX34R-EN...

- Page 103 S S t t a a r r t t u u p p Figure 94. 25.4 Ton operating pressure — high efficiency (50 Hz) Figure 95. 29.2 Ton operating pressure — high efficiency (50 Hz) RT-SVX34R-EN...

- Page 104 S S t t a a r r t t u u p p Figure 96. 33.3 Ton operating pressure — high efficiency (50 Hz) Figure 97. 41.7 Ton operating pressure — high efficiency and standard efficiency CV (50 Hz) RT-SVX34R-EN...

Page 105: Noises

Page 106: electric heat units, page 107: for single zone variable air volume, page 108: sequence of operation, page 109: economizer operation based on reference enthalpy, page 110: modulating hot gas reheat sequence of, page 111: constant volume (cv) unit fan, page 112: variable air volume (vav), page 113: occupied heating operation, page 114: modulating hot gas reheat, page 115: low pressure control (lpc) sequence of operation (reliatel control), page 116: maintenance.

- Page 117 M M a a i i n n t t e e n n a a n n c c e e Table 66. Belt tension measurements and deflection forces Deflection Force (Lbs.) Steel Cable 358 Gripnotch Belts Super Gripbelts Gripnotch Gripbelts 358 Gripbelts...

Page 118: Monthly Maintenance

Page 119: cooling season, page 120: coil cleaning, page 121: refrigerant coils.

- Page 122 M M a a i i n n t t e e n n a a n n c c e e RT-SVX34R-EN...

Page 123: Fall Restraint

Page 124: charge storage, page 125: vfd programming parameters.

- Page 126 M M a a i i n n t t e e n n a a n n c c e e g. Ensure parameter 14-22 Operation Mode has 4. Follow the start-up procedures for supply fan in the reverted back to “Normal Operation”. “Variable Air Volume System”...

- Page 127 M M a a i i n n t t e e n n a a n n c c e e Table 72. Supply fan VFD programming parameters Menu Name Unit Language English US 0-01 Regional Settings 0-03 North America Set to applicable unit power supply 200-240V/60Hz for 200 &...

- Page 128 M M a a i i n n t t e e n n a a n n c c e e Table 72. Supply fan VFD programming parameters (continued) Menu Name Unit Terminal 53 Low Ref./Feedb. 6-14 Value Analog In/Out Terminal 53 High Ref./Feedb.

Page 129: Diagnostics

- Page 130 D D i i a a g g n n o o s s t t i i c c s s depending on the type of meter used. Some meters N N o o t t e e : : Since CV units may use a conventional may only pulse between 20 and 30 volts DC.

Page 131: Diagnostics (Vav Only)

- Page 132 D D i i a a g g n n o o s s t t i i c c s s Smoke Detector Switch Table 74. Resistance values (continued) The LED will flash anytime that the N.O. Smoke Zone or Set Detector input is closed and will be reset anytime that Point Nominal ZTEMP...

- Page 133 D D i i a a g g n n o o s s t t i i c c s s directions, LED is open. If low in both directions, Table 76. Constant volume and single zone VAV default operations LED is shorted.

Page 134: Procedures

Page 135: reliatel air module (rtam) tests, page 136: reliatel air module (rtom) tests, page 137: troubleshooting.

- Page 138 D D i i a a g g n n o o s s t t i i c c s s Table 79. Troubleshooting (continued) SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION 1. Perform OAS Resistance/Temperature check. 1. OAS has failed. Replace if necessary.

- Page 139 D D i i a a g g n n o o s s t t i i c c s s Table 79. Troubleshooting (continued) SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION M. Low Heat Capacity Intermittent Heat. (YC’s only) CFM runs in LO or HI Check CFM, test LO and HI speed windings.

- Page 140 D D i i a a g g n n o o s s t t i i c c s s Table 79. Troubleshooting (continued) SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION 1. Check the return air sensor (RAS) at connector P10 by disconnecting P10 from RAT on the ECA.

- Page 141 D D i i a a g g n n o o s s t t i i c c s s Table 80. Component failure mode (continued) COMPONENT FAILURE RESPONSE NORMAL RANGE DIAGNOSTIC If a sensor is used at RTRM J6-1 and J6-2, Cannot control at ZSM, unit Cool Failure Output at RTRM J6-8 to J6-6 HSP and CSP for CV or SZ VAV...

Page 142: Tr-200 Vfd Programming

- Page 143 D D i i a a g g n n o o s s t t i i c c s s W W A A R R N N I I N N G G Use [▲] and [▼] buttons to adjust the digit Press [Cancel] button to disregard change, or H H a a z z a a r r d d o o u u s s V V o o l l t t a a g g e e w w / / C C a a p p a a c c i i t t o o r r s s ! ! press [OK] to accept change and enter the new...

Page 144: Unit Wiring Diagram Numbers

- Page 145 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 82.

- Page 146 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 82.

- Page 147 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 83.

- Page 148 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 83.

- Page 149 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 84.

- Page 150 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 84.

- Page 151 U U n n i i t t W W i i r r i i n n g g D D i i a a g g r r a a m m N N u u m m b b e e r r s s Table 85.

Page 152: Warranty And Liability Clause

- Page 153 N N o o t t e e s s RT-SVX34R-EN...

- Page 154 N N o o t t e e s s RT-SVX34R-EN...

- Page 155 N N o o t t e e s s RT-SVX34R-EN...

- Page 156 For more information, please visit trane.com or tranetechnologies.com. Trane has a policy of continuous product and product data improvements and reserves the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.

Rename the bookmark

Delete bookmark, delete from my manuals, upload manual.

DEALER LOCATOR

Find your Trane comfort specialist

What You Need To Know About Low NOx HVAC Requirements

Find out how California’s commitment to reducing greenhouse gas emissions can impact your home and what energy-saving options are available to you.

In an effort to lower greenhouse gas emissions 40% by 2030, some areas of California are regulating the nitrous oxide (NOx) emissions of residential gas furnaces. In addition, several communities are encouraging electric only or electrification mandates for all new residential construction. While this may sound confusing, the good news is that whether you’re in California or not, Trane® has a heating solution that can meet these environmentally friendly regulations and could lower your energy costs over time compared to traditional gas furnaces.

Our goal: Low greenhouse gas emissions. High-quality heating comfort.

Greenhouse gases are bad for the environment and bad for your health. According to the EPA, nitrogen oxides contribute to respiratory problems, acid rain, smog, elevated algae levels, and global warming 1 . Greenhouse gas emissions attributable to residential buildings in California currently represent about 25% of the state’s total emissions. 2 And the largest source of greenhouse gas savings comes from eliminating on-site combustion of natural gas 3 .

What is Low NOx or Ultra-low NOx?

NOx is an abbreviation for nitrogen oxides — a collection of harmful and toxic greenhouse gases. These gases are released when fuel is burned at high heat like in an engine or home gas furnace. Low NOx and Ultra-Low NOx refers to emission limits on these products and are determined by local EPA standards and will vary for each type of heating equipment.

What are the HVAC Low NOx regulations in my area?

If you live in California, any heating equipment you buy may need to conform to local EPA standards as set forth by the South Coast Air Quality Management District . California’s South Coast Air Quality Management District (SCAQMD) and the San Joaquin Valley Air Pollution Control District (SJVAPCD) introduced Ultra-Low NOx Rule 1111 and Rule 4905, respectively, which require NOx emissions of less than 14 nanograms per joule.

Our Low NOx solution: Install a zero-emission heat pump.

Trane heat pumps are an electric heating source that are environmentally friendly, energy-efficient and meet all current Low NOx and Ultra Low NOx regulations. Heat pumps can both heat and cool your home, so if you currently don’t have central air or have a traditional split system, a heat pump can keep you more comfortable year-round, and use less energy to do it. In fact, based on Southern California’s mild climate, heat pump space heating averages about 4 to 6 times greater efficiency than natural gas furnaces. 4

Why a heat pump is right for you.

- Zero emissions: The new Low Nox and Ultra-Low NOx standards are meant to make gas furnaces more environmentally friendly by reducing the amount of harmful greenhouse gasses they emit. This is great, but you know what’s better than low NOx emissions? ZERO emissions! A heat pump is 100% electric, so there are no fossil fuels burned in the heating process — making it a far more environmentally friendly heating choice than a gas or oil furnace.

- Versatility: A heat pump acts as an air conditioner and heating system in one self-contained unit. This versatility makes it a great solution in homes where space is limited.

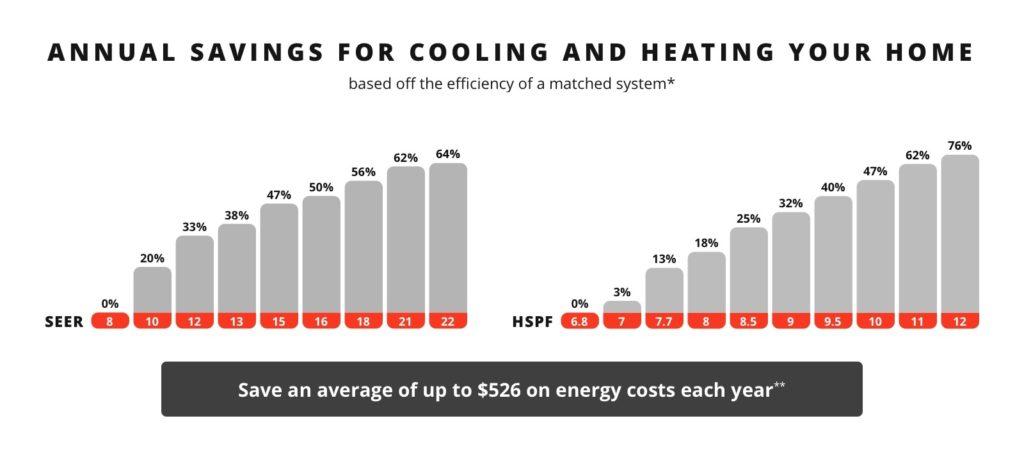

- Ultra-efficient: Unlike a furnace, a heat pump doesn’t burn fuel to make heat. It simply uses electricity to move heat from one place to another — making it a more energy-efficient solution. Our most advanced heat pumps are ENERGY STAR® Qualified and deliver top SEER and HSPF ratings as well as other energy-saving technologies that can help lower your energy costs. Energy analysts encourage the installation of high-efficiency HVAC heat pumps rather than standalone central air conditioning units plus gas furnaces whenever possible 5 .

See how much you can save with a zero-emission heat pump.

The higher the system SEER and HSPF ratings, the more comfort you’ll get from each energy dollar.

How do the new Low NOx or Ultra-Low NOx standards affect your heating system?

If you live in one of the newly regulated areas, any new heating system you purchase will need to conform to the local emission standards. You may also have the opportunity to switch out a gas furnace for a more efficient one or a zero-emission solution like a heat pump. Your local government or utility provider may even offer incentives to make the switch to a more energy-efficient solution.

Electrification. What it is and why it’s the smart solution to limit greenhouse gas emissions.

The American Wind Energy Association defines electrification as:

Electrification, also known as energy conversion, refers to the transition across all economic sectors to electricity-powered end-use technologies. For example, the transition from diesel to electricity-powered battery buses, or the shift to air-source heat pumps and heat pump water heaters.

Many city planners and local governments are looking for ways to limit greenhouse gas emissions by promoting or mandating the use of electricity as a power source as opposed to fossil fuels like natural gas. Even if your neighborhood isn’t mandating electrification now, more and more communities will be looking for similar solutions. That’s why now is a good time to get ahead and invest in a heating solution that meets all emission standards and delivers the comfort you expect — like an energy-efficient heat pump.

Heat pump myths — it’s time to set the record straight

Heat pump technology has been around since the 1940s. While today’s models are far more efficient than earlier generations, several myths and misconceptions about heat pumps and the comfort they deliver continue to persist in the minds of many homeowners. It’s time to set the record straight.

Myth: Heat pumps are only for heating. Truth: Names can be misleading. Heat pumps use a mechanical-compression refrigeration system that can either heat or cool your home depending on the season. This means you only need one system year-round to maintain a comfortable temperature indoors. Myth: Heat pumps only work in warm climates. Truth: Heat pumps can handle temps as low as 0 degrees Fahrenheit. One of the biggest misconceptions about heat pumps is that they only work in more temperate climates — not true. Most efficient heat pumps, like Trane systems with their Climatuff® Variable Speed Compressor , can handle temperatures as low as 0 degrees Fahrenheit for average-sized homes. Myth: Heat pumps are expensive and have a limited lifespan. Truth: Heat pumps can actually save you money over time and last as long as other systems. Heat pumps are generally cheaper than the combined cost of a new gas furnace and standalone central air conditioner, and energy savings are seen in most homes as well. 6 In addition, a heat pump will generally last 15-20 years — which is comparable to furnaces and air conditioners

Final thought

Switching to a heat pump for increased home comfort, more year-round efficiency, and lower emissions is a win for you as a consumer — and it’s the responsible thing to do for the quality of life in California. For even more information about Trane heat pumps , check out our heat pump vs. furnace guide and our heat pump myth busting article .

1. EPA.gov: https://www.epa.gov/no2-pollution/basic-information-about-no2#Effects 2. Residential Building Electrification in California, April 2019. Energy and Environmental Economics. Page i. 3. https://www.ethree.com/wp-content/uploads/2019/07/CA_Res_Building_Electrification_Final_Presentation.pdf 4. Residential Building Electrification in California. April 2019. Energy and Environmental Economics. Page 86. 5. Residential Building Electrification in California. April 2019. Energy and Environmental Economics. Page 27. 6. Residential Building Electrification in California. April 2019. Energy and Environmental Economics. Page 27.

Related articles

Boost your HVAC knowledge

By pressing “submit,” I understand that I am providing express consent for Trane Residential to contact me about this request or similar topics. I can unsubscribe and opt-out from future communications at any time. See our Privacy Policy for more information.

Getting Started Guide

Learn helpful HVAC tips and tricks before you purchase your system.

Warranty & Registration

A healthy HVAC system can last longer and save money. Maintain your system with these tips.

IMAGES

VIDEO

COMMENTS

Optimize HVAC performance with building connectivity. Voyager 3 units are capable of integrating into building automation and control systems for optimization, monitoring and data analysis. New models are equipped with the Symbio® 700 controller for improved usability and automated optimization. Symbio's intuitive user interface displays ...

Voyager 2 - 12.5 - 25 Tons Voyager 3 - 27.5 - 50 Tons. We know time is money. You can have your Voyager unit in two to three weeks - the fastest delivery in the industry - to help keep projects on track and get job sites up and running quickly. Choose from Voyager 2 or Voyager 3 models to meet the needs of a broad range of small, medium to ...

IntelliPak rooftop units set the bar for durability and value. With a portfolio of three distinct products and industry leading efficiencies, the Intellipak product is designed to serve a range of application and regulatory needs. IntelliPak 1 - 20-130 Tons. IntelliPak 2 - 90-150 Tons. IntelliPak 3 - 20-75 Tons.

View and Download Trane Voyager manual online. Product. Voyager air conditioner pdf manual download. Sign In Upload. Download Table of Contents Contents. Add to my manuals. Delete from my manuals. ... Packaged rooftop air conditioners with reliatel controls and estage 27.5 to 50 tons - 60 hz, 22.9 to 41.7 tons 81-148 kw - 50 hz (156 pages) ...

Voyager® Commercial Heating and Cooling Rooftop Units. Voyager® 2 - 12.5 - 25 Tons & Voyager® 3 27.5 - 50 Tons. Key Features: Available in gas/electric, electric/electric & heat pump only for Voyager 2. Dependable MERV filtration that removes contaminants as small as 0.3 microns.

Voyager™ 3 Packaged Rooftop Air Conditioners with Symbio™ ... 50 Hz/3 phase: TC*, TE*, YC*, 275C, 305C, 350C, 400C, 500C ©2024 Trane RT-SVX089B-EN Introduction Read this manual thoroughly before operating or servicing this unit. Warnings, Cautions, and Notices Safety advisories appear throughout this manual as required. Your personal ...

† The Trane Voyager Rooftop has, by far, the best COP in its class. All performances are Eurovent certified which provides the assurance of accurate performance and common comparison criteria. Rigorous Testing † All of Voyager's designs were rigorously rain tested at the factory to ensure water integrity. † Rigging tests include lifting a ...

Trane solutions optimize indoor environments with a broad portfolio of energy efficient heating, ventilation and air conditioning systems, building and contracting services, parts support and advanced control. For more information, visit ingersollrand.com or trane.com. Reporters may contact: Liz Soltoff, [email protected], 732.652.6952.

Clarksville, Tenn., Oct. 15, 2013 — Trane® PrecedentTM (3- to 10-ton) and VoyagerTM (12.5- to 25-ton) light-commercial rooftop unit offerings now include Trane technological innovations that not only offer the lowest installation cost, but also a reduction in utility bills and maintenance requirements. Introduced by Trane, a leading global ...

roll compressorCompressors• Voyager contains the best Scroll compressor technology available, in order to achieve the h. ghest performance possible. The Trane VoyagerTM rooftop has amon. the best COP in its class. All performances are Eurovent certified which provides the assurance of accurate performance an.

View and Download Trane Voyager Commercial installation, operation and maintenance manual online. Packaged Rooftop Air Conditioners with ReliaTel Controls and eStage 27.5 to 50 Tons - 60 Hz, 22.9 to 41.7 Tons 81-148 kW - 50 Hz. Voyager Commercial air conditioner pdf manual download.

Voyager™ 12.5 to 25 Tons Packaged Rooftop Units Cooling & Gas/Electric Table 1. Model number description T*D Cooling Only (Electric Heat Optional), Downflow T*H Cooling Only (Electric Heat Optional), Horizontal Y*D Gas Heat Unit, Downflow Y*H Gas Heat Unit, Horizontal * Standard (S) or High (H) Efficiency Table 2.

These configurations can be used with standard cooling systems. This guide provides information about the configuration, control capabilities and troubleshooting of the. Voyager system with Symbio 700 controller. BAS-APG048*-EN Application Guide Symbio™ 700 Controller with Voyager 3 Packaged Rooftop Air Conditioners. WARNING:

High Efficiency Motors Trane® Communication Interface (TCI)(h) (h)TCI is for use with non-VariTrac™ systems and VariTrac systems. ... Voyager 12 1/2 - 25 Ton Packaged Rooftop Units Cooling and Gas/Electric - Models T/YSD, T/YSH, T/YHD, T/YHH / Quick Reference Guide Author: TCS- Unitary Subject: Voyager 12.5-25 Ton Cooling & Gas/Electric

EXPLORE THE RANGE OF TRANE HEATING & COOLING SOLUTIONS. XV19 Variable Speed Heat Pump is designed with limited space in mind, this unit will meet the needs of difficult-to-install or tight space required homes such as zero lot line, condos, or under decks. With Trane TruComfort™ technology, the system automatically adjusts itself while maintaining constant and consistent speeds to avoid ...

The free download of Trane Symbio™ Service and Installation mobile app is available on the App Store® for iOS, and on Google Play® for Android™. Figure 1. Trane Symbio™ Service and Installation mobile app Bluetooth Pairing Quick Connection Instructions Follow these instructions to quickly connect the mobile app to the Symbio™ 700 ...

Voyager 2 - 12,5 - 25 toneladas Voyager 3 - 27,5 - 50 toneladas. Sabemos que el tiempo es dinero. Puede tener su unidad Voyager en dos o tres semanas, la entrega más rápida de la industria, para ayudar a mantener los proyectos en marcha y poner los sitios de trabajo en funcionamiento rápidamente. Elija entre los modelos Voyager 2 o Voyager 3 ...

The US Air Force recently commissioned its first LNG plant at a strategic air base, aiming to improve energy efficiency and reduce costs. Learn how a collaboration with Trane, the Defense Logistics Agency, Tokyo Gas Engineering Solutions, and the 35th Fighter Wing resulted in a journey of resiliency and innovation.

Companies who choose to create and/or install a commercial furnace that does not meet local NOx emission requirements face hefty daily fines. Our Ultra-Low NOx Solution. Trane electric and dual-fuel heat pumps meet today's Low NOx and Ultra-Low NOx regulations. Moreover, they offer premium energy efficiency, sustainability and affordability ...

NOx is an abbreviation for nitrogen oxides — a collection of harmful and toxic greenhouse gases. These gases are released when fuel is burned at high heat like in an engine or home gas furnace. Low NOx and Ultra-Low NOx refers to emission limits on these products and are determined by local EPA standards and will vary for each type of heating ...