- Sustainability

- Worldwide Presence

- Global Policies

- Knowledge Center

- Stock Information

- Press Releases

- Financial Information

- Events & Presentations

- Leadership & Governance

- Email Alerts

Discover our latest Sustainability Report, covering our performance and actions during 2022, to ...

- Award-Winning E-Turbo

- Electric Compressor for Mild Hybrid Vehicles

- Alternative Fuels

- Turbo Technology

- Split Compression VNT Turbo

- Wastegate Turbochargers

- Variable Geometry Turbo

- Small Wastegate Turbos

- Variable Geometry Turbos

- Two-Stage Parallel Turbos

- Double Axle VNT

- Wastegate and Free Floating Turbos

- CV Two Stage Serial Turbos

- How a Turbo Works

- 3 in 1 E-Axle

- E-Cooling Compressor

- Hydrogen Fuel Cell Compressor

- Intrusion Detection System

- Security Operation Center

- Advanced Controls & System Optimization

Gain access to thought leadership and practical knowledge to increase your expertise in ...

- How to Choose a Turbo

- Turbochargers

- Turbo Intercoolers

- Turbo Wastegates

- Turbo Accessories

- Vehicle Turbocharger Kits

- Garrett Classic Turbo

- Digital Catalog

- Boost Experience

- Where to Buy

- Performance Shop

- Garrett Original Equipment

- Garrett Original Reman

- Garrett Redboost

- Service Replacement Checkpoint

- Turbo Replacement Catalog

- Installer Connect Training

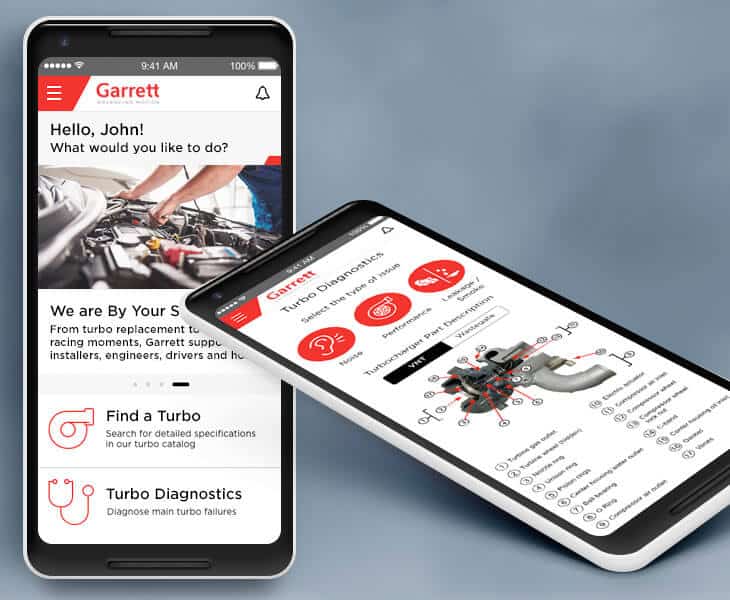

- Garrett Connect App

Mobile app for mechanics and automotive enthusiasts to easily access Garrett's tools...

Purchase performance products from our Authorized Distributors.

- Why Join Garrett

- Working at Garrett

- Graduates & Students

- Job Opportunities

Sr. Procurement Project Manager Trupti Shinde inspired by learning and the opportunity ..

Great technology starts with amazing people. Everyone at Garrett Motion helps create ...

When Wayne Kim joined Garrett’s Connected Vehicle Software Team in Korea, he was ...

Turbochargers Intercoolers

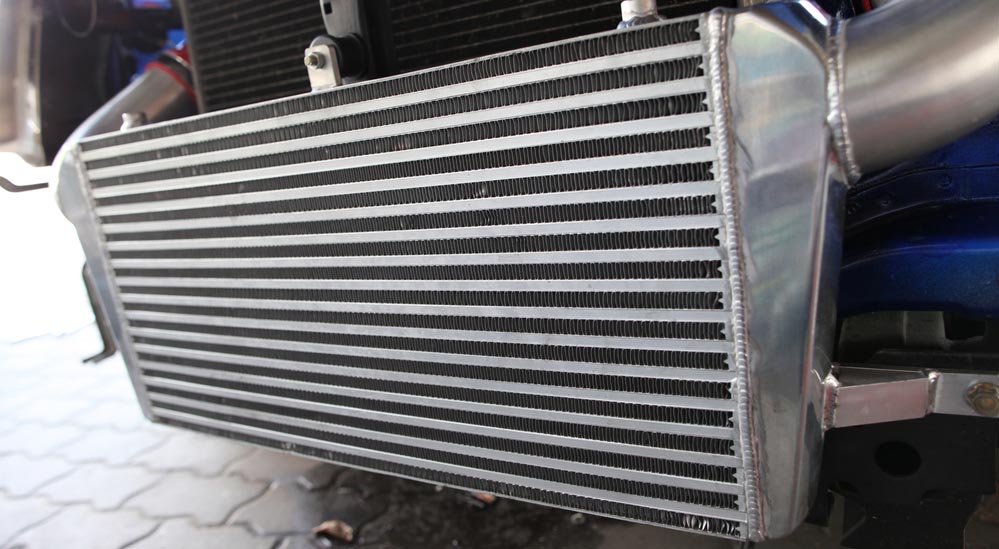

Utilizing advanced Aerospace technology, Garrett performance turbo intercoolers offer superior fatigue protection for the high boost pressures and temperatures of today’s extreme engines. Reduce intake temperatures and increase horsepower.

Garrett Intercoolers and Intercooler Cores

Garrett intercoolers offer superior thermal fatigue protection for high boost pressures and temperatures of today’s extreme engines. We engineer and manufacture complete intercoolers for vehicle specific applications, and intercooler cores for custom builds. Select from our large offering of air-to-air cores that support from 300 – 1275 horsepower, and our air-to-liquid cores that range from 500-1000 horsepower.

Superior Thermal Protection

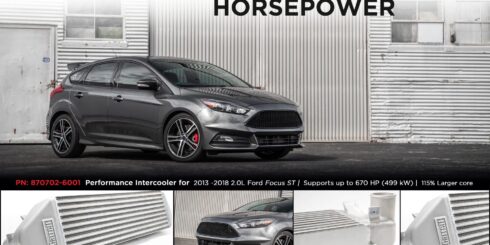

Powermax vehicle specific drop-in intercoolers.

Garrett PowerMax drop-in intercoolers are engineered to increase vehicle performance while maintaining OEM fitment. Advanced CFD combined with bar and plate core technology results in in lower intake temperatures and prolonged heat saturation.

Air-To-Air Intercooler Cores

A full range of bar and plate intercooler cores that are manufactured by Garrett technicians. Our bar and plate intercooler cores are proven to reduce intake temperatures through advanced fin density and offset composition.

* Horsepower rating shown for normal operating conditions, Maximum horsepower potential will be higher than the listed values.

Air-To-Liquid Intercooler Cores

Turbochargers intercoolers and intercooler cores.

Utilizing advanced Aerospace technology, Garrett intercoolers offer superior fatigue protection for the high boost pressures and temperatures of today’s extreme engines. With over 75 years of charge air cooler experience, Garrett remains ahead of the industry in intercooler design and function making it the number one choice for some of the premier names in the performance car industry – Roush, Saleen, Mercedes-Benz AMG, Ford SVT, GM, and McLaren have all turned to Garrett to intercool their hottest models.

A full range of bar and plate intercooler cores that are manufactured by Garrett technicians. Our bar and plate intercooler cores are proven to reduce intake temperatures through advanced fin density and offset composition. From air-to-air cores sized for sport compact cars to air-to-liquid cores capable of supporting 1000+ hp, find the perfect fit for every project, at the perfect price with Garrett.

Vehicle specific intercoolers Selecting the right intercooler core Air-to-air cores Air-to-liquid cores Intercooler Technology

Selecting The Right Intercooler

We manufacture a wide range of air to air intercooler cores rated from 310 horsepower applications up to 1260 horsepower applications. Each core is rated for a specific horsepower, making it easy to match your desired power target to the core. In general, use the largest core that will fit within the packaging constraints of the application.

Learn More About Thermal Tech

Garrett Performance Intercoolers

Performance Intercoolers Garrett performance intercoolers and intercooler cores work together with the turbocharger as part of the total induction system. When air is compressed in…

Intercooler Tech: What Is Fin Density

Intercooler Tech: Fin Density In the first intercooler article we talked about heat transfer and selecting the best intercooler for your application. (Click here to…

Intercooler Sizing And End Tank Design With Rob Dahm

Rob Dahm rethinks, redesigns, and retests his current intercooler and end tanks to unlock more horsepower on his 4 rotor RX7. Using CFD analysis, he identifies where the current setup has restrictions that are causing pressure drop and robbing Rob’s 4 Rotor of horsepower

2013 – 2018 Ford Focus ST Performance Intercooler

Replace Heat With Horsepower PowerMax performance products by Garrett Motion are vehicle specific turbo and intercooler upgrades for the most popular OEM turbocharged…

Garrett Performance Intercooler Test: 2016+ Honda Civic Si

MotoIQ tests the new Garrett drop-in performance intercooler for the 2016+ Honda Civic Si. 17HP and 14 lb-ft of torque gained over stock when tested in a wind tunnel dyno, all from a drop-in unit.

Garrett Intercooler upgrade for the 2.3L Ford Mustang

Garrett has released a new drop-in intercooler upgrade for the 2015 and newer Mustang 2.3L EcoBoost engine platform. The 857564-6001 intercooler is C.A.R.B. certified and…

Making Power With The PowerMax Twin Turbo and Intercooler Upgrade For 3.5L F-150

PowerMax Performance For Your Ford F-150 If you are looking for a little extra power for your ecoboost engine, Garrett PowerMax turbos and intercoolers are…

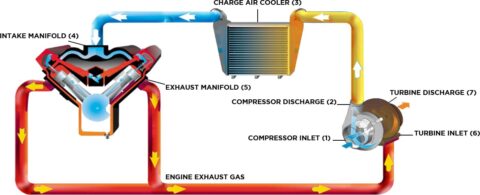

Performance Intercoolers

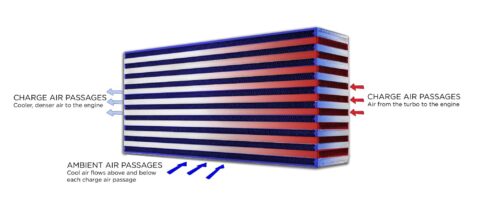

Garrett performance intercoolers and intercooler cores work together with the turbocharger as part of the total induction system. When air is compressed in the turbocharger it gains a lot of heat. Hot air is less dense and therefore is not able to produce as much energy because less can be fed into the engines cylinders. The job of the intercooler is to remove heat from the charge air making it more dense. The denser charge equals more air and fuel reaching the engine and that translates to more horsepower.

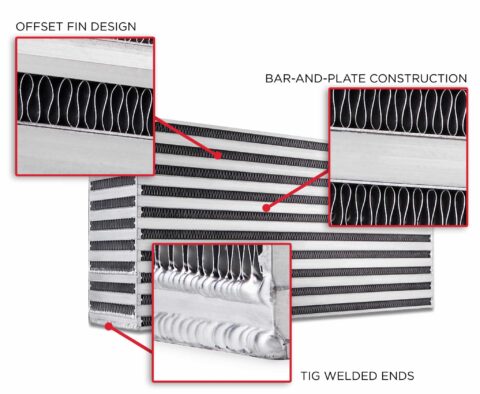

Intercooler Construction

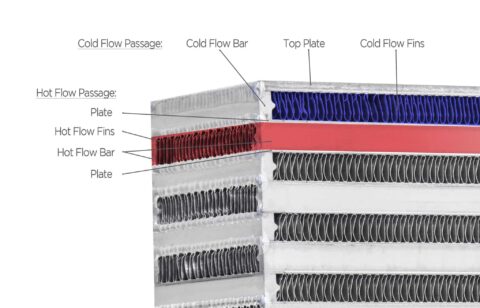

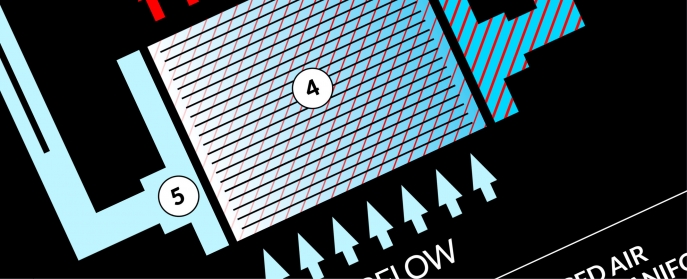

Garrett intercooler cores are bar and plate horizontal flow design. Charge air from the turbo flows within enclosed passages in one direction, with separate cooling passages flowing cooler ambient air in a perpendicular cross-flow pattern to the charge air. In bar and plate designs the passages consist of plates on top and bottom with fins in between. The passages are enclosed by bars on either side depending on if it is a charge air passage or an ambient air/cooling passage. Passages are stacked alternately until the desired stack height is reached. On the sides of the stacked cores, added to the final passage is a side plate of thicker material to provide structural integrity, protect the more delicate fins, and provide a surface for welding on end tanks if desired.

Heat Transfer

How does the intercooler remove heat from the charge air? There are three types of heat transfer modes, but the bar and plate intercooler relies on Conduction and Convection to extract heat from the charge air. Conduction is the transfer of heat to materials that have direct contact with each other. Convection is the transfer of heat from one place to another by movement of air. As you can see in the image below, the bars, plates, and fins alternate direction and flow and all play a part in extracting heat from the charge air. The charge air fins transfer heat from the charge air to the plates and the ambient air fins transfer the the heat from the plates and the ambient air cools the fins. The process repeats as long the car is moving or until the core gets heat soaked.

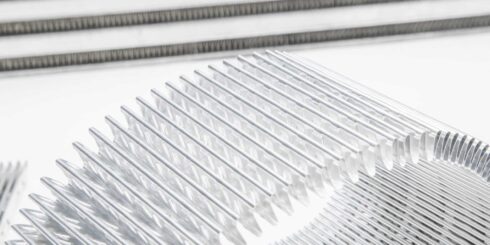

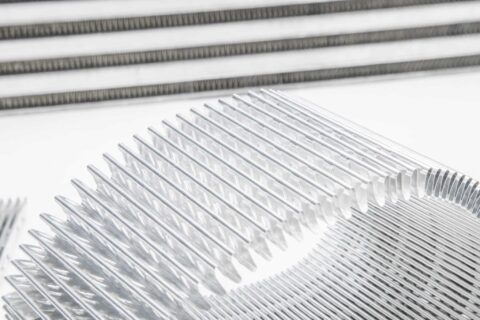

Fin Density

Fin density is measured in FPI or fins per inch. Each fin surface counts as one fin meaning there are two fins per wave. Fin stacks start off as flat sheets of aluminum that are fed through a special machine where they are bent to the desired FPI per row height and length. Garrett manufacturers around 20 different air-to-air and air-to-liquid intercooler cores supporting a range of horsepower from 310 up to 1260. Each of those cores are different in length, width, and height to meet the needs of different performance enthusiasts.

Garrett Intercooler cores utilize a combination of fin density depending on the flow path of the core. For example, the cold flow path or the front of the intercooler commonly has a higher density fin count to allow for better thermal performance and cooling. Core width/ cold flow can range from 3 – 5 inches so higher fin density is critical with the short span the ambient air travels across to cool the charge air passages. Additionally, the cold air passages are not sealed or pressurized like the charge air passages, so your ambient air flows through, cools the hot passages and evacuates into the engine compartment.

Hot flow passages have a longer run spanning from 11-28 inches in some intercooler cores. The hot flow path is a series of sealed chambers with fins spanning the entire length. There is a lot of surface area for heat transfer to take place and for that reason, the hot chambers have a lower fin density. This also helps reduce pressure drop as the charge air travels from one side to the other.

Pressure Drop

Pressure drop is the difference in pressure between two points caused by flow resistance. An example of pressure drop is when the air pressure leaving the intercooler is less than the pressure that went in. You may never actually see this happening because your turbo will work harder (spin faster) to deliver the correct PSI to the engine. The faster a turbo spins the hotter the air is so it’s critical to use an intercooler that has a good balance of fin density so you don’t overwork the turbo.

Think about driving down the road with your hand out of the window and your palm facing forward. Your hand is interrupting the flow of the air and it must find a way around your hand to pass. Now imagine you and 10 friends in a limousine with your hands out of the window one after another. The last person in line will not feel the same flow as the first person because of pressure drop.

Choose your path

Follow the journey of your preference, for more relevant information

I’m a vehicle owner

who needs to replace the turbo. Find a partner distributor in your area

I’m a performance enthusiast

Discover stunning engine tuning products

I’m an oem representative

Request information for your needs

I’m a distributor/garage

Start gaining recognition as a Garrett Turbo Installer

I'm interested in Garrett - Advancing Motion

Find out more information about our culture

Stay in touch

- Garrett Worldwide Presence

- Why Join Us

- Expert Voices

- Events Calendar

- Fuel Cell Technology

- Award-Winning E-Turbo Technology

- Automotive Cybersecurity

- Advanced Controls and System Optimization

- On Vehicle Performance

- Performance Turbos

- Performance Products

- Boost Adviser

- GarrettGear

- E-order (Aftermarket)

- Promo Builder

- Garrett on Linkedin

- Garrett on Twitter

- Garrett on Youtube

- Garrett on Instagram

- Garrett on Facebook

- Turbo Diagnostics

- Aftermarket Turbochargers – Turbo Identification

- Aftermarket & Reman Turbochargers Catalog

- Garrett Installer Connect Training

- Insist on Garrett

- Terms & Conditions

- Privacy Statement

© 2024 Garrett Motion Inc.

Let's Connect

Sign up to receive exclusive communications about offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication (e.g., communications through social media platforms), collectively “marketing communications”.

If you would like to be unsubscribed from marketing e-communications*, from Garrett Motion Inc, click here .

*Marketing communications refers to communications about offerings, news and events, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication (e.g., communications through social media platforms).

If you are a current customer, you will not be unsubscribed from transactional and other non-marketing communications, such as communications containing important information related to a product or service you have purchased.

If you would like to unsubscribe from all marketing communications from Garrett Motion Inc. and its affiliates and subsidiaries, click here .

Universal Opt Out

By providing your email address, you will be unsubscribed from all marketing communications* from Garrett Motion Inc. and its affiliates and subsidiaries.

Page unavailable in this language!

We apologise but this page is not available in your selected language, . Please go back and choose a different language to view the content. We apologise for the inconvenience.

You will be redirected to the new Installer Connect turbo catalog.

Example of Garrett Part Number

STANDARD FORMAT: 721021-5006S

- A standard Garrett part number consists of 6 digits before the dash and 4 digits after the dash, followed by “S”.

- The system will recognize the number with or without the dash.

OE AND OES VARIATIONS

- A standard Aftermarket (IAM) part number always begins with “5” after the dash. (For example: 721021-5006S)

- The OES part number differs from the IAM part number only in that it does not have the “S” at the end. (For example: 721021-5006)

- The OE part number differs from the IAM part number in 2 areas: it begins with “0” after the dash. it does not have the “S” at the end. (For example: 721021-0006)

Login using your email address

Or login with, garrett employees & partners, create an account with us to access exclusive content and stay connected..

First Name *

Last Name *

Country * Afghanistan Albania Algeria American Samoa Andorra Angola Antigua and Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas, The Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Bulgaria Burkina Faso Burma Burundi Cambodia Cameroon Canada Cape Verde Cayman Islands Central African Republic Chad Chile China Colombia Comoros Congo, Democratic Republic of the Congo, Republic of the Costa Rica Croatia Cuba Cyprus Czech Republic Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Ethiopia Faroe Islands Fiji Finland France French Guiana French Polynesia Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guatemala Guinea Guinea-Bissau Guyana Haiti Holy See (Vatican City) Honduras Hong Kong (China) Hungary Iceland India Indonesia Iran Iraq Ireland Israel Italy Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Korea, North Korea, South Kuwait Kyrgyzstan Laos Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Macau (China) Macedonia Madagascar Malawi Malaysia Maldives Mali Malta Martinique Mauritania Mauritius Mexico Micronesia, Federated States of Moldova Monaco Mongolia Montserrat Morocco Mozambique Namibia Nepal Netherlands Netherlands Antilles New Caledonia New Zealand Nicaragua Niger Nigeria Norway Oman Pakistan Palau Panama Papua New Guinea Paracel Islands Paraguay Peru Philippines Poland Portugal Puerto Rico Qatar Reunion Romania Russia Rwanda Saint Helena Samoa San Marino Saudi Arabia Senegal Serbia and Montenegro Seychelles Sierra Leone Singapore Slovakia Slovenia Somalia South Africa Spain Sri Lanka Sudan Suriname Swaziland Sweden Switzerland Syria Taiwan (China) Tajikistan Tanzania Thailand Togo Tokelau Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan Venezuela Vietnam Virgin Islands Yemen Zambia Zimbabwe

Email Address *

Confirm Email Address *

Password *

Or register with

You're almost there one more step to complete your registration..

To proceed, you'll need to choose at least one option below that matches your profile.

Your personal data will be used to support your experience throughout this website, to manage access to your account, and for other purposes described in our privacy policy .

Please check here if you wish to receive future communications from Garrett, including notices of product updates or other promotional or technical information. We use this information in strict accordance with our Privacy Statement .

By signing up, you are providing consent for Garrett Advancing Motion, Inc. and its affiliates and subsidiaries to contact you through e-communications, which refers to email, social media and digital advertising. By opting in here, you’re consenting to receive communications from the Garrett Advancing Motion business. You can withdraw your consent at any time here .

- CALL TODAY (913) 338-2886

PROCHARGER INTERCOOLERS: HIGH PERFORMANCE THROUGH INNNOVATION

(Click for Larger Image)

Everyone knows that ProCharger is committed to building industry leading superchargers systems for street cars/trucks, and that we are almost unrivaled in the racing market. But did you also know for the past 20 years ProCharger has also been leading the way in bringing you highly effective air-to-air intercoolers, with the largest choice of sizes/models to ensure both effectiveness and flow are maintained not only for stock motors, but modified motors as well?

It’s true, intercoolers play a huge roll in creating high HP while also maintaining engine reliability in a supercharger system. However, this important part is often never mentioned when comparing supercharger systems. In this blog we will cover the items that set the ProCharger intercoolers apart from the rest, to help illustrate what gives our supercharger systems the coolest air charge temperatures, and thus the largest, most reliable power gains available.

ProCharger was the original, introducing the aftermarket’s first intercooled supercharger system over 20 years ago, a major innovation and nearly 3 years ahead of its nearest competitor. And that innovation continues. For all of the vehicles listed below, ProCharger offers the largest, most effective intercoolers with the broadest range of intercooler options.

Design For starters, ProCharger uses the highly effective (and durable) “Bar and Plate” design for street/strip intercooler cores-the core itself is not only engineered to be of the proper size for the application, but also the core “spacing” of the bars and plates to ensure proper airflow flow to fluid systems behind the intercooler (IE: Radiator/Condenser).

(Photo shows height of core stack)

One of the often overlooked aspects of an intercooler is weight. We all know that if its lighter, its faster, so with that in mind ProCharger engineers design light weight stamped sheet metal aluminum end tanks for our intercoolers, instead of commonly used (heavy) cast aluminum air-to-air units – not to mention the weight of a pump, secondary heat exchanger, coolant reservoir and coolant of an air-to-water-to-air intercooler system. ProCharger intercoolers are also of the highest quality, always manufactured at the ProCharger plant in Kansas City.

Testing When testing/designing intercoolers, ProCharger has a three-fold approach: 1) Intercooler designs begin as 3D computer models 2) Intercoolers are tested in an Aerodynamic test cell 3) Intercoolers are installed and tested in the real world, at the track and on dyno

ProCharger not only tests to ensure the pressure drop across the core’s flow path is at its absolute lowest, but also checks for proper temperature reduction between inlet and outlet. When intercoolers are being tested for their effectiveness, we are looking for the coolest air charge possible, but we also want to make sure the supercharger isn’t working to hard to “push” air through the core itself. The computer models and test cell data can help us build a great performing core right out of the gate. The final piece of the puzzle is “real world” testing at the track to see how the intercooler works with the rest of the cars cooling system, as well as adequate aerodynamics.

Sizing and Options Another important aspect that sets ProCharger apart is that for most of our systems, we offer multiple interercooler sizes (or arrangements) to best fit your HP goals or driving habits. In this next part of the blog we will illustrate some of the various sizing and lay out options available for a few different supercharger systems.

For the 2011+ 5.0L Mustang, the animation below illustrates (3) different intercooler options in the form of the HO intercooler system, Stage 2, and Race. The HO intercooler features a highly efficient crossflow intercooler core for stock or slightly modified applications. Our Stage 2 offering swaps to a large side to side flow core that is 3.5″ thick offering great flow for modified applications pushing the power levels. For those going for the ultimate in charge cooling, the Race Intercooler with 4.5″ thick core can be ordered that features a MASSIVE 1296 cubic/inch Cooling Core! As you can see all (3) intercoolers fit behind the factory 5mph impact bumper, and no modification to the car is needed for installation.

HO Intercooler = 540 cubic/in Cooling Core Stage 2 Intercooler = 1008 cubic/in Cooling Core Race Intercooler = 1296 cubic/in Cooling Core

The C7 Stingray Corvette is a car that is just at home on the road course as it is at the drag strip. At ProCharger we knew having an intercooler layout for each was needed. So using the same massive 972 cubic inch cooling cores, we developed both horizontal and vertical layouts, to match different driving habits. We recommend the vertical style unit for drag racing applications where high hp and absolute maximum cooling of the air charge is needed in short bursts. The horizontal unit is better-suited for road racing applications, where long periods of wide-open-throttle demand maximum airflow to other factory cooling systems.

Vertical Intercooler = 972 cubic/in Cooling Core Horizontal Intercooler = 972 cubic/in Cooling Core

The next animation shows the two intercooler options available for the 2011+ 6.4L SRT Challenger. The HO intercooler features a high flow, top-to-bottom core design that maximizes available airflow through the cars front fascia. However, for those pushing horsepower/boost levels, and wanting the largest air-to-air intercooler available for new HEMI-powered cars, the Race Intercooler option with its 970 cubic inch core is also available.

Stage 2 Intercooler = 423 cubic/in Cooling Core Race Intercooler = 970 cubic/in Cooling Core

One of the most modified platforms we sell superchargers for is the new Gen 5 Camaro SS. To ensure we have the perfect intercooler for its wide range of power levels, ProCharger is happy to offer (2) different intercoolers. Much like as the 2011+ Mustang 5.0L, the base HO system offers a high-flowing vertical core design for stock or mildly modified vehicles. For those pushing the power levels with modified motors or using their Camaro SS for heads-up racing, we offer the Race unit that switches to a side-to-side core and 4.5″ thick core, for the ultimate in charge temp cooling.

HO Intercooler = 486 cubic/in Cooling Core Race Intercooler = 1296 cubic/in Cooling Core

For those truck lovers out there, we didn’t forget about you–below you can take a peak at the two different intercooler options available for the Ford F-150 Raptor. The Stage 2 intercooler is standard with its high flow vertical core design, and the Race intercooler option is for truck racing applications, or where low speed/high load conditions demand even higher intercooling efficiency (such as towing, etc).

Stage 2 Intercooler = 486 cubic/in Cooling Core Race Intercooler = 1296 cubic/in Cooling Core

For more information on intercooling in general, including the benefits of air-to-air vs air-to-water-to-air for street use, please visit our Intercooling page HERE

Thanks for reading, and if you have any questions or comments, please feel free to reach us at 913-338-2886 or email us at [email protected]

View Similar Articles

PROCHARGER SUPERCHARGERS' F-150 KITS PACK A PUNCH!

Performance and power you can feel! ProCharger Superchargers F-150 systems offer an incredible performance boost like no other…

Rust to Rockin! ‘69 Camaro Installs ProCharger's SBC Accessory Drive Kit

From starting this story as a parts car rusting away in an Oklahoma field to strutting its stuff fully restored and making the 2500-mile cruise for PowerTour, Jacob Dietz and his father’s 1969 Chevrolet Camaro fully embody the spirit of car culture!

Installing a ProCharger Supercharger System On The Trail

To put our claims to the test, OffRoad Xtreme took their ProCharger system to the desert of Johnson Valley, CA, home to the prestigious King of the Hammers off-road race. Armed with nothing more than a bag of hand tools and their 2017 Toyota 4Runner, they embarked on the on the trail installation adventure.

EPIC POWER FOR YOUR GM 6.6 GAS SUPERCHARGER

2020-23 GM 6.6L L8T V8 HD owners can now get the BOOST in performance they crave by bolting on a ProCharger supercharger to get 50% more power to pull, pass, and play (on pump gas)!

SIGN-UP FOR THE LATEST PROCHARGER NEWS

Emissions compliance.

ProCharger offers Executive Orders for Emissions Compliance (EO) from California Air Resources Board (CARB) for many of our most popular car, truck and SUV applications. If you live in California, we can only sell you products with EO certification. Check out our full list of EO offerings.

- Summit Racing Equipment

Search Form

Recent searches.

- Hot Rods and Muscle Cars

- Old Motorcycles

Trending Searches

- Ford Bronco

- Record Setting

- Fuel Injection

Intercooler Guide (Part 2): Intercooler Construction and How it Affects Performance

In our Intercooler Guide (Part 1) post, we covered the differences in air-to-air and liquid-to-air intercoolers and provided some general advice from Mishimoto about which might be right for you. Once you’re done making that choice, you’ve still got some important decisions to make.

In Part 2 of our guide, we’ll show you how construction can influence the effectiveness of an intercooler and further help you make good decisions for your application. With help from our friends at Mishimoto , we’ll cover the three main areas of an intercooler: core, end tanks, and piping. Each one of these areas plays a key role in the effectiveness of the intercooler.

Core Construction

Selecting a good quality core is essential when choosing an intercooler for your ride.

But then again, you get what you pay for.

Here’s a quick comparison, courtesy of Mishimoto:

Fin style and density also play a part in the performance of an intercooler. More fins equal better heat exchange; however, high fin density will reduce airflow through the intercooler. Finding the right balance can be a challenge, but intercooler manufacturers use a variety of equations and testing to come up with the optimal solution for each application. This often includes experimenting with the pitch and overall height of the fins to create the right amount of surface area.

Another consideration is core size. The bottom line is bigger is not always better when it comes to intercooler core size. A properly sized intercooler will deliver efficient cooling without impacting boost lag.

Mishimoto put together a handy chart to match core size to your vehicle’s horsepower.

In the chart, the “high-density core measurement” of an intercooler can be determined by using a couple of equations.

Core Area (in²) = Core Length (in.) x Bar Height (in.) x # of Bars

For example, a 22-inch long core with 12 bars that measure .3 inches will equate to:

Core Flow Area = 22 x .03 x 12

Core Flow Area = 79.2 in ²

Once you know the Core Flow Area, you divide that number by .45 to determine the Charge-Air Surface Area.

Charge-Air Surface Area (in²) = Core Flow Area (in²) /.45

For our example, that means we have:

Charge-Air Surface Area = 79.2 in² / .45

Charge-Air Surface Area = 176 in²

Lastly, you divided the Charge-Air Surface Area by the core thickness to determine the Internal Flow Area, which is denoted as the “high density core” measurement in the chart.

Internal Flow Area (in²) = Charge-Air Surface Area (176 in²) / Core Thickness (3.75-inch)

Internal Flow Area = 47 in²

According to the chart, this intercooler would be effective up to 500 horsepower.

The right end tank is a major factor in the longevity of your heat exchanger and have a big effect on the airflow through the core. There are four common materials used for end tank construction: plastic, stamped aluminum, cut-and-weld aluminum, and cast aluminum.

Plastic end tanks are used on stock intercoolers, but they are not ideal for performance applications. These end tanks are not well equipped to handle increased performance or higher boost levels. As a result, they can outright fail during high-boost pulls.

Aluminum tanks are recommend for performance applications. Stamped aluminum tanks are the most budget-friendly aluminum option and can easily handle high-boost applications. However, you’ll most commonly find stamped aluminum end tanks paired with standard tube-and-fin intercoolers. Cut-and-weld aluminum end tanks are considered a step up from stamped tanks. A well made cut-and-weld tank provides fantastic durability; however, since it incorporates multiple pieces of aluminum welded together, proper testing and precision welding is required.

Cast aluminum end tanks are at the top of the spectrum. These tanks offer the best combination of reliability and smooth airflow. Because there are no welds, there are no potential failure points. And since the internal structure is smoother than cut-and-weld tanks, engineers can optimize the airflow to the entire length of the core.

Outlet/Piping Size

You will have to match your piping to the outlets on your intercooler. Therefore, the size of the outlets are important, especially when you consider the effect of intercooler pipe size on performance. It really is a delicate balance between airflow and horsepower output. For example, piping too large will require greater flow to produce boost, causing lag. Conversely, piping too small will limit the power output.

Mishimoto recommends you run the smallest piping possible without causing restrictions. The company offers this chart to make the choice a little easier.

As you can see, a three-inch pipe is capable of handling in excess of 800 horsepower—adequate for many performance setups.

Armed with this information, you’re well on your way to choosing the right intercooler for your vehicle.

Happy intercooler shopping!

David Fuller is OnAllCylinders' managing editor. During his 20-year career in the auto industry, he has covered a variety of races, shows, and industry events and has authored articles for multiple magazines. He has also partnered with mainstream and trade publications on a wide range of editorial projects. In 2012, he helped establish OnAllCylinders, where he enjoys covering all facets of hot rodding and racing.

One response to “Intercooler Guide (Part 2): Intercooler Construction and How it Affects Performance”

Tube and fin are the better cores that’s why they are used in F1, WRC, Touring cars and many more motorsports.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Similar Stories

Ask away with jeff smith: understanding the relationship between tdc, cam position & harmonic balancer timing marks on a sbc, tips for selecting an accessory drive system that'll work (& fit) perfectly in your ls swap project, tips and tricks for routing a wiring harness.

- The Workshop

Turbo Intercooler Systems: Types & Function

- No comments

- 7 minute read

Demystifying Onikyan Style: Japan’s Car Camber Culture

Vivek Shingada

Share article

Heat is the single biggest enemy of performance, especially when it comes to forced induction.

If your intake charge temperature isn’t regulated and lowered, it will sap a ton of power and lower the overall efficiency of your engine.

Regardless of whether you have a turbocharger or supercharger installed, the hot and compressed air being forced into your engine needs to be appropriately cooled before it enters the combustion chamber.

That’s exactly what intercoolers help with.

With an intercooler installed, you can significantly lower the intake charge temperature, prevent unnecessary damage, and free up lost power.

But installing one of these is a lot easier said than done. It begins with knowing how it works, what the different types are, and which one to choose for your particular application. That’s what we’ll discuss in this guide.

What Does an Intercooler Do?

Intercoolers are air intake cooling devices that are commonly used on engines fitted with some form of forced induction.

They work just like radiators do, and that’s why the two components look so similar. There are passageways for the warm air to pass through, and there’s a heat exchanger — a system used to transfer heat.

Let’s take a closer look at what goes on inside an intercooler when it’s in active use.

How Does an Intercooler Work?

The supercharger vs. turbocharger debate is a hot topic. Though the two work very differently from one another, they pretty much do the same thing: force large amounts of air into the engine to make more power.

Heat is an inevitable part of air compression. No matter how advanced your turbo or supercharger is, without an intercooler, the compressed air that it generates will carry a lot of heat with it.

An intercooler’s primary function is to cool down that warm air before it reaches the combustion chamber.

Wondering why you need the intake air temperature to be lower? The cooler the air, the denser it is. This means it carries more oxygen — something you need to ensure proper combustion.

When the intake charge is less dense, it doesn’t mix and burn with the fuel properly.

This negatively affects the air-fuel ratio and creates a domino effect of various other problems like detonation, excessive fuel consumption, and loss of volumetric efficiency.

That’s why it’s best to do everything you can to cool down the air from the exhaust system before your turbo pumps it back into the cylinder.

Arguably, intercoolers are far more necessary on turbochargers considering how they depend on the exhaust stream to spin the turbine wheel. But they’re equally important for supercharged engines as well.

The intercooler kicks into action the moment you start your car. Follow the airflow path and you’ll see exactly what goes on under the hood. Let’s consider the airflow path of a turbocharged engine for instance.

Initially, the first charge travels through the intake tract and into the cylinder where it mixes with fuel, gets compressed, burns, and converts to exhaust.

It is then pushed out through the exhaust valve and into the exhaust manifold . Some of this exhaust is then sent into the turbo where it spins the turbine wheel and the compressor wheel as a result.

What you then get is compressed air which passes through a discharge port and heads straight into the intercooler, where it cools down.

After that, it flows back into the manifold, where it makes its way back into the cylinder, and the cycle continues.

Types of Intercoolers

Now that you know what the turbo intercooler does, let’s get a better understanding of how the different types of intercooled turbos work.

There are two main types: air-to-air and liquid-to-air. The main difference between the two is the heat transfer agent they use.

Air-to-air intercoolers rely on ambient air to cool down the warm air, while water-to-air intercoolers rely on water to do the same. Below we’ve explained how both these types function.

Air-to-Air Intercooler

Air-to-air intercoolers are typically mounted on the front of the engine bay, right behind the front bumper for better accessibility to outside air.

They’re very commonly used; they’re cheaper, lighter, and simpler in contrast to air-to-water intercoolers.

The only drawback of this intercooler type is the longer intake length. Because of the way they’re mounted, more tubing is required, and it takes much longer for the air to travel from the turbocharger to the engine.

This often results in wider fluctuations in temperature. Heat soak, when stationary, can also be a problem as they rely on ambient airflow generated as a result of the vehicle being in motion.

The engine fan assists with the cooling in this situation, but it can only do so much.

In terms of core design, there are two options you can choose from: tube-and-fin, or bar-and-plate.

Tube and Fin

Tube-and-fin intercoolers are made up of a network of a passage of tubes called “passes” and cooling fins — the wave-like metal structures that form a mesh by spanning across the front surface of the intercooler.

Compressed air travels through the tubes which are connected to a series of fins. When the vehicle is in motion, the ambient air hits these fins and cools down the hot air as a result.

This design is more commonly seen on cheaper stock and OEM-replacement intercoolers.

Bar and Plate

Bar-and-plate intercoolers are stronger, heavier, and more expensive. But, they provide better heat dissipation and cooling characteristics.

They comprise a series of plates and bars welded together to make channels for the hot air to flow through. Together, they do the job of a heat sink.

These types of intercoolers are a lot more durable and can take more abuse compared to the tube-and-fin design.

Water-to-Air Intercooler

Water-to-air intercoolers are also called liquid-to-air or charge air coolers. The primary heat transfer agent in this design is either water or coolant.

As the hot air is circulated through the intercooler, heat is transferred from it to the coolant that passes through adjacent passages, cooling the air down as a result.

The cooled air is channeled into the engine, and the water goes into a separate radiator as it needs to be cooled after absorbing heat from the compressed air.

Water-to-air intercoolers are perfect for smaller, cramped engine bays owing to their compact size.

They’re also more expensive to manufacture and require the use of additional complex components such as an auxiliary radiator, a thermostat, extra piping, a water reservoir, and a water pump.

There are more components to this system which leads to a higher price tag, but it’s certainly more efficient.

This increased efficiency is why the liquid-to-air intercooler is growing in popularity as more and more drivers try to get the most out of the engines.

Choosing the Right Intercooler

Now that you know the basics of what intercoolers are and how they work, let’s take a closer look at some of the considerations you need to make when choosing one for your car.

Below we’ll discuss the impact of intercooler size, fin density, mounting location, and pressure drop.

When selecting an intercooler, it’s important to choose a size that is appropriate for the amount of boost you intend to run.

You don’t want to use an intercooler that’s bigger than you need because you’ll lose pressure as the air travels from the inlet to the outlet.

Choose too big of a core size and you’ll end up with more lag. 3” to 3.5” is standard for most street cars.

Selecting the right Inlet and outlet size is also important. Though they’re usually the same in most aftermarket intercoolers, some manufacturers provide varying inlet and outlet sizes for high-boost applications. This helps to control the pressure drop.

An inlet of 2.5” and outlet of 3.5” or even 4” to 4.5” is commonplace for high boost applications.

Pressure Drop

Pressure drop is the difference between the air pressure at the inlet and the outlet of the intercooler.

Ideally, you want a low-pressure drop somewhere in the range of 1 or 1.5 psi and lower. Anything more than 3 psi is considered inefficient.

Well-designed intercoolers can achieve the right fin density, and the right size, while still keeping the drop at an acceptable level, without putting too much stress on the turbo.

Fin Density

Fin density is typically measured by calculating the number of fins per inch, also called FPI. This isn’t something you can measure by yourself, and this information can only be found on the manufacturer’s website.

The higher the fin density, the more air can be trapped in the fins, and the more effective the overall cooling will be. However, the more fins you have in your charge path, the more restricted the airflow will be.

Aftermarket intercooler manufacturers strive to achieve the perfect balance between optimal airflow and cooling by carefully engineering the right fin density.

Mounting Point

When it comes to mounting your intercooler, there are two viable options — either on the top of the engine or right behind the front bumper. These are called top-mount and front-mount intercoolers, respectively.

Both mounting options are ideal for cooling down the compressed air, but if you’re looking to install an aftermarket intercooler and can’t decide on where to mount it, then we recommend going with a top-mounted intercooler.

Firstly, air needs to travel a shorter distance to reach the intercooler if it is top-mounted, resulting in reduced turbo lag. Secondly, this mounting option utilizes engine bay space effectively and leads to better heat dispersion.

But while a top-mounted intercooler might be the preferred mounting location on paper, it’s worth questioning whether front-mounted ones are any good in the real world.

The short answer is yes. In fact, in daily driving conditions, you won’t be able to tell the difference between the two systems because they’re so comparable.

But if you’re measuring the efficiency of each system and trying to figure out the exact horsepower and turbo-lag time, the top-mounted intercooler has the advantage every time.

Even though an intercooler is not mandatory for forced induction, it’s always advisable that you install one.

It’s worth mentioning that your experience with installing one of these will differ based on your engine layout.

For cars that have a front-mounted engine, the process is quite straightforward. But for mid or rear-engine cars, expect to deal with a more complicated setup.

What’s your intercooler setup of choice? Let us know by leaving a comment below!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Choose country

- United Kingdom

- United States

Search results

Find a manual, simple guide to the air to air turbo intercooler, you are here.

When air is drawn into the turbocharger, boosted, and then forced into the engine, it gets very hot. And hot air isn’t as good for an engine as cool air. Therefore many turbocharged engines make use of an intercooler.

An intercooler is basically an air-to-air radiator. The hot air from the turbo enters at one end, and as cooled as it passes through the intercooler (much like the water in a car’s radiator) before entering the engine at a much lower temperature.

This allows the engine to make full use of a simple principal of physics; cooler air is more dense than hotter air.

This basically means that for a given volume (of our engine’s cylinder for example) we can get more oxygen into the same space when the air is denser – and more oxygen means better performance.

3 common intercooler faults

01 Leaking boost hoses

There’s not much that can go wrong with an intercooler, so most faults are usually either associated with installation issues or physical damage resulting in boost leaks.

One of the most common areas affected is the rubber boost hoses and the clamps that hold them inn place. Over time the rubber will perish, and clamps can lose their clamping force, which can result in the boost hoses actually allowing boosted air to escape.

This would result in a sluggish, underperforming car, and you may even be able to hear a ‘whooshing’ sound (although not always) as you can actually hear the air leak when driving.

The fix is quite simple; new hoses and clamps.

02 Impact damage

As the intercooler sits right at the front of the car it does mean it is susceptible to damage, particularly from stones and debris from the road hitting the intercooler.

This can damage the delicate cooling fins, reducing the cooling efficiency of the intercooler, and is extreme cases and also damage the tubes through which the boosted air passes through.

The most common effect is an underperforming intercooler, resulting in increased inlet air temperatures, but in the worst cases the intercooler can piece and you can end up with a boost leak.

The fix requires a new intercooler.

03 Oil contamination

As the air that enters the intercooler comes directly from the turbocharger, it does mean that if you’ve ever had any issues with the turbo then the intercooler is likely to be affected too.

For example, if a turbo is suffering from an oil leak die to worn seals, then the oil that has ‘leaked’ out has to go somewhere – and the somewhere is most likely to be the intercooler.

This means the oil gathers in the bottom of the intercooler, reducing the performance of the intercooler itself. It also introduces oil vapours to the boosted air, so will have a negative affect on engine performance too.

To check, remove the boost hoses and inspect for signs of oil contamination. If there are any, remove the intercooler and flush our with engine degreaser to remove all the oil from the inside of the intercooler.

Recommended for you

Latest Tips & Tutorials

- Toggle navigation

- 1-480-966-3040 8am-5pm MST

- Create Account

- VR Performance

- Agency Power

- VR/AP Warranty

- Product News

- Client Cars

- Tuning and Tech

- Project Cars

- The Deal Machine

- Affirm Financing

- Katapult Leasing

- Extend Warranty

- Military Discounts

- Price Matching

- International Orders

- Service and Tuning

- Our Guarantees

- Shipping Claim

- Terms and Conditions

- Shipping and Returns

- Privacy Policy

Now Offering 0% Financing With Affirm! Select Your Option At Checkout! - Learn More

Shop For Your Vehicle

Forge motorsport intercooler upgrade porsche 997 gen 2 turbo.

Forge Motorsport

Model #FMINT997G2

Product Options

One of our experts would be happy to help you navigate these options and get the exact part you need. We can contact you via phone or email.

Great! We'll be contacting you shortly.

- Description

About Forge Motorsport

- For Instructions CLICK HERE

- Porsche 997 Gen 2

- In line with our policy to constantly review, revise, and improve our product range, the appearance of the product you receive may differ from the one advertised.

https://www.P65Warnings.ca.gov

Forge Motorsport is a world leader in aftermarket car parts, that includes actuators, intercoolers, blow-off valves, fabricated alloy tanks, big brake kits, wastegates, and silicone hoses. The company was founded in 1996 with the simple principles of innovation, crafty designs, and high-quality manufacturing. The company is comprised of passionate petrolheads who are dedicated to designing and developing vehicle-specific performance parts for OEM And turbocharged applications.

If you are looking to get the most out of your Audi, BMW, or Volkswagen’s performance, you can count on Forge Motorsport in the United Kingdom. Each individual Forge branded product proudly states “Made In Great Britain.” Forge Motorsport is based out of Gloucester, England, where its headquarters and manufacturing plants produce its ever-growing lineup of products. The company also has a full sales and distribution facility in Orlando, Florida (Forge USA) and one in Taichung, Taiwan (Forge Asia)

Forge Motorsport’s Manufacturing Process

All Forge Motorsport products are manufactured in-house in its state-of-the-art CNC machine shop by a team of highly skilled engineers and fabricators. All Forge production is controlled by the international ISO 9002 standard for manufacturing design and development. Billet parts are machined to the strictest tolerances and undergo exhaustive testing and inspection before they are released. All welding is also done in-house, by Forge’s in-house craftsmen, and boasts unsurpassed quality and robotic-like precision. Not only do Forge Motorsport’s products look great but they also perform second to none. What’s more, all Forge products are guaranteed for life and backed by Forge’s “No Hassle” service promise.

With immense knowledge at its disposal, Forge is honored to supply the leading names and race teams in the world of motorsport, including F1, Rally X, WRC, and Le Mans, as well as several OEM manufacturers.

Forge Motorsport at Vivid Racing

Vivid Racing carries a wide array of Forge Motorsport parts, including intercoolers, big brake kits, blow-off valves, wheel spacers, wastegates, turbo hoses, intakes, radiators, and much more! If you cannot find a specific item above or have any general questions, please do not hesitate to call our expert sales team at (480) 966-3040. We are here to make the buying experience a simple and pleasant one.

Check out these other great products

Racing Dynamics Intercoolers Hose Kit Porsche 996 | 997 Turbo 1997-2013

Model #137 11 06 998

Racing Dynamics Intercoolers Hoses Porsche 996 | 997 Turbo 1997-2013

Model #137 11 06 997

Racing Dynamics Hi Performance Intercoolers Porsche 996 | 997 Turbo 2000-2013 137

Model #137 10 96 996

AMS Performance Intercooler system Porsche 997.2 Turbo 10-13

Model #ALP.09.09.0002-2

$3,729.95 $3,618.05

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

FREE SHIPPING ON ORDERS OVER $100! SHOP AUTO // SHOP TRUCK

- Sponsorship

What intercooler should I get? Is this a good intercooler? What horsepower gains will I see with this intercooler? Is a universal intercooler right for me? We all see these questions on Internet message boards, and we even hear them in friendly discussions with fellow car folk. Instead of responding with a face palm, we need your help to educate the masses on how an intercooler works. Knowing what makes a great intercooler great is powerful knowledge that can help you select the best cooler for your project.

The goal of this article is to explain intercooler systems, designs, features, and testing procedures, so that you can more easily select the intercooler that meets your needs. Don’t be that guy with a massive front-mount intercooler on a completely bone-stock vehicle complaining about boost lag. Check out the guide below to educate yourself, your friends, relatives, maybe even that guy at work claiming his three-fifty will blow the doors off your measly 4-banger. With our help here at Mishimoto we will make sure when you are looking to buy a Focus ST intercooler , that you actually find the right model intercooler to make your car better.

This article includes information from basic intercooler function to advanced discussion about core design and heat transfer. Feel free to utilize the table of contents below to skip around to sections that interest you.

Table Of Contents

1. Intercooler Function (CAC Basics) A. Turbocharger B. Piping and Boots C. Intercooler

2. Intercooler Types A. Liquid-to-Air B. Air-to-Air C. Which Should I Build?

3. Where's The Cooler? A. Top-Mount (TMIC) B. Side-Mount (SMIC) C. Front-Mount (FMIC)

4. End-Tank Construction A. Plastic B. Stamped C. Cut-and-Weld Aluminum D. Cast Aluminum

5. Core Construction A. Tube-and-Fin vs. Bar-and-Plate B. Fin Styles C. Fin Density D. Optimal Airflow (Core Placement)

6. Inlet and Outlet Sizing A. Staggered Inlet/Outlet Sizing

7. Core Volume and Surface Area A. Intercooler Sizing Example

8. Surface Finish A. Powder-Coated B. Painted C. Anodized D. Durability E. Heat Transfer

9. Maintenance

11. Testing A. Intake Temperatures and Efficiency B. Pressure Drop C. Power Output

12. Conclusion

1. intercooler function (cac basics).

We’re going to start this article with some basic knowledge needed to fully understand how a charge air cooler (CAC) system functions to improve the power of your vehicle. Let’s begin with a fun pop quiz. What were the first turbocharged production vehicles? Stop opening a new tab to google this … Unless you include commercial vehicles developed by the Swiss, the answer is GM’s 1962 Oldsmobile Jetfire and Chevrolet Corvair.

The point behind this question is that turbocharging technology has been around for quite some time, but the technology did not come into its own in production vehicles until the 1980s. We can thank the fuel crisis for the introduction and widespread use of turbochargers, whose purpose was to produce greater power without a significant impact on fuel economy. Such advances in automotive technology allowed manufacturers to turn lemons into lemonade, and they set the tone for several decades of successful turbocharger improvements and implementation.

Now, you can walk into just about any car dealership and spot a turbocharged model in seconds. So let’s look into how these systems function to improve power output while retaining fuel efficiency.

A. Turbocharger

Before jumping into the actual intercooler kits , we need to see why a turbocharger is even necessary. A turbocharger is an interesting piece of machinery. In a nutshell, the turbo recycles the engine’s exhaust gases by compressing intake air before entering the engine. When this compressed air is forced into the cylinders to mix with the fuel, more power can be made. For readers who are visual learners, reference the image below.

So as you see in this image (starting at the upper right), ambient air enters the turbocharger from the intake system, is compressed, and exits the housing heading toward the hot-side intercooler pipe.

Once through the intercooler, the now cold air passes through the cold-side intercooler pipe and into the throttle body (or intake manifold in vehicles without a throttle body).

Let’s discuss the internal portions of a turbocharger. An impeller is spun by the exhaust gases that enter the rear portion (exhaust housing) of the turbocharger. This impeller is connected to a shaft that runs the full length of the turbo to the compressor side. As the compressor spins, air is compressed, and the intake air enters the engine. Although it seems complex, the functionality is pretty basic: Compressed intake air pressurizes the intake system, resulting in a positive manifold pressure for producing more power.

If you prefer to keep things truly simple, this definition from the BBC’s Jeremy Clarkson is always a good bet: “Exhaust gases go into the turbocharger and spin it, witchcraft happens, and you go faster.”

B. Piping and Boots

Something needs to route air from your turbocharger to the other key components of the system. This is where intercooler piping and boots (couplers) come into play. Factory piping is typically constructed from steel or plastic, while aftermarket setups are usually made of aluminum. Either way, the piping will curve around the engine bay, going from the turbocharger, to the intercooler, then to the engine intake manifold. Couplers provide a connection point between these components while providing flex and serviceability of the individual pieces. We put together another article about piping and boot systems and how to put together a reliable system. For more information on that, check out the link below.

http://www.mishimoto.com/engineering/2014/11/boots-blowouts-and-boost-tubes-how-to-build-a-reliable-cac-piping-system

C. Intercooler

The almighty intercooler is a heat exchanger that transfers heat from one fluid to another. (Note: Engineers consider gases as “fluids,” because all principles and equations used to predict gases and fluids are identical.) In this case, hot air is entering the internal portion of the intercooler from the turbocharger. Although temperatures will vary based on the engine and turbocharger specs, we typically see inlet temperatures in the range of 225°F–275°F (107°C–135°C). As air passes through the external fins of the cooler, heat is transferred, resulting in a reduced temperature for air exiting the intercooler

So why would we want a colder temperature? As we all know, a combustion engine relies on a combination of air and fuel, ignited to produce our favorite tire-spinning activity. One key to producing optimal power is air density. The cooler the air, the more dense it is. Higher density will result in more oxygen content within the mixture, which allows for more fuel and a more efficient explosion that results in greater power. The goal for any vehicle is to reduce intake temperatures as close to ambient as possible. To do so on a turbocharged vehicle, a heat exchanger is absolutely needed.

Additionally, engine detonation (“knocking”) is far more common with high intake temperatures. Detonation occurs when a combustion process spontaneously takes place after normal combustion caused by the spark plug. This causes an instantaneous pressure spike within the combustion chamber. By reducing intake temperatures and improving combustion, we can reduce the chance of ignition detonation.

Detonation can be quite ugly and can result in overheating and severe engine damage. You want to avoid it like the plague. As long as you have a solid ECU tune and low intake temperatures, detonation should not be a concern.

So begins the journey to find the perfect intercooler for your street car, tire-shredding drag car, twin-turbo track rat, lemon budget build, AWD rally animal, twin-engine hill-climb monstrosity, or any other build or project you might have in the works.

2. Intercooler Types

There are basically two types of intercoolers: liquid-to-air and air-to-air. The decision between the two coolers is usually a matter of efficiency, power output, and vehicle use.

A. Liquid-to-Air

Just as the name implies, the liquid-to-air cooler uses engine coolant (typically on a secondary engine coolant circuit) to transfer heat from the air passing through it. The coolant and air are in different passages and do not make direct contact. This particular heat exchanger is extremely efficient and is actually finding its way into the engine bays of numerous OEM vehicles, including the 6.7L Powerstroke, the CLA45 AMG, and the BMW S55B30. I imagine this will be commonplace in the near future because of the improvements to its efficiency and component packaging.

In a liquid-to-air cooler, coolant is pumped through the channels and tubes that are attached to the fins in the heat exchanger. Air from the turbocharger flows through the fins, which allow for the transfer of heat between the air and coolant. A system such as this typically uses a low-temperature thermostat to regulate fluid temperatures.

Liquid-to-air systems are typically used for very high-powered vehicles that produce a great deal of heat. This system is more complex than a typical air-to-air intercooler, because it requires coolant lines, fittings, a coolant pump, and possibly an additional radiator, and it occupies a reasonably-sized footprint for the actual exchanger. Adding this type of complexity to the system is truly only worth the hassle for vehicles requiring substantial heat exchange. For most vehicles, a more typical air-to-air cooler is efficient enough for street and track use.

B. Air-to-Air

When someone speaks of an intercooler, the air-to-air more commonly comes to mind. This cooler will normally be visible from the exterior of the vehicle, such as when mounted within the front bumper. The reason for this is airflow. This cooler relies on airflow through the core for it to have an impact on CAC temperatures.

Referencing the image above, you can see the internal channels for airflow. This particular core is a bar-and-plate unit, which is discussed later on in this article in our Core Construction section. Air will pass through the channels of this cooler created by the bars and plates. On the outside of the cooler, finned rows are located between each bar. As air passes through these fins, heat is exchanged with the internal air, thus reducing temperatures.

An air-to-air system is very efficient; however, it does rely on airflow (from vehicle speed) to generate the needed cooling. At idle, these coolers can be prone to heat-soak when there is insufficient airflow. Although this is rarely an issue for front-mount setups, an air-to-air unit contained within an engine bay can certainly overheat at idle when engine bay temperatures begin to affect the cooler.

In general, this type of cooler is far more popular within the automotive world and offers the best monetary value in terms of cooling performance. For these reasons, the majority of this article will focus on air-to-air units and their features.

C. Which Should I Build?

Check out the pro/con chart below highlighting the benefits and downfalls of each system. This should help you weigh the options to go down the right route for your build.

The primary drawback from purchasing a liquid setup is cost, which can be as much as two to three times the cost of an air-to-air setup, depending on the components used. As noted above, most users will be able to extract the needed cooling performance from an air-to-air setup.

3. Where's The Cooler?

Several acronyms used in intercooler discussions might confuse those not acquainted with automotive jargon. They reference the location of the intercooler and are explained below.

A. Top-Mount (TMIC)

The top-mount intercooler (TMIC) is fairly commonly used for stock heat exchangers. Two of the more popular vehicles equipped with such a system are the Subaru WRX and STI.

The name indicates the location of the cooler, which is on top of the engine. This type of cooler is supplied airflow via a hood scoop or some form of ducting from the front grille.

Placing the cooler in the engine bay has a few key benefits. First, this cooler is in a safe location to avoid any road debris from damaging it. Imagine you are slinging your turbocharged behemoth down a rally stage, and an errant rock decides to lodge itself in your bumper-mounted cooler. Not good. An additional benefit would be in terms of boost lag. Because the intercooler is so close to both the turbocharger and intake systems, piping will be extremely short, which allows for a shorter airflow route and less boost lag.

As with any setup, there are certainly a few downsides to a TMIC system. Heat-soak is going to be the primary problem. Since the intercooler is located within the engine bay, it will certainly be susceptible to the heat generated by your engine and exhaust system. Intake temperatures tend to rise with a TMIC at idle, which can negatively affect power output if the cooler gets too hot. Upgrading from the factory cooler to a larger bar-and-plate unit will certainly help reduce the risk of heat-soak, but the only way to eliminate it would be to select a different location for the cooler.

B. Side-Mount (SMIC)

A side-mount intercooler (SMIC) is fairly uncommon these days, but at one point it was factory equipped on a few vehicles, including the 90s DSMs, the Nissan Silvia, and a variety of VAG vehicles. This cooler could be considered a bit of a compromise between the other two choices and is typically only a factory-equipped setup. In this system, the cooler is placed toward the front of the vehicle on one of the side inlets of the bumper. Instead of blocking airflow through the center portion of the bumper, the SMIC pulls air from the side of the bumper.

Due to space constraints, the size of this cooler is normally pretty limited, which would influence power support. Also, piping needs to be longer to route air outside the engine bay and back in. For mild builds, an upgraded SMIC will work. For anything pushing decent power, most people will prefer a more beneficial FMIC upgrade.

C. Front-Mount (FMIC)

A front-mount intercooler (FMIC) is not only a modification for lower intake temperatures, but it also provides some aesthetic presence. A large, bumper-mounted intercooler is an easy way to identify a fellow car guy. There are several debates regarding the use of an FMIC vs. a TMIC in terms of boost lag and actual power benefits. While a front-mount system will typically produce the lowest intake temperatures of all options, it will also incur the most boost lag. This shortcoming needs to be considered, depending on your vehicle’s power as well as your intended driving plans, but for optimal heat transfer, this is the system you want.

The intercooler in this system sits in the front bumper opening where it can achieve optimal airflow through the core. This cooler will impede airflow to the radiator behind it, which then causes a restriction in airflow through that heat exchanger. This setup could adversely affect coolant temperatures. It is not usually a big issue but is certainly something to keep in mind.

To summarize, your choice of intercooler setup will be dictated by your vehicle and goals. For optimal heat transfer, an FMIC is the way to go. For reduced boost lag and increased power support for mild modifications, a TMIC may be best for you.

For assistance in selecting an appropriate intercooler type for your vehicle, the best bet is to hit some enthusiasts’ forums and see what the collective groups recommend. Of course, we’re always here to help.

4. Let's Talk End Tanks

Although end tanks may seem a bit insignificant compared to the core of your intercooler, you would be surprised at the number of failures caused by poor end-tank design. Selecting the right type of end tank can help shape the long-term reliability of your heat exchanger and can also play a big role in actual airflow through the core. If your tank design is not efficient at moving the airflow your vehicle generates, you will not be able to take full advantage of that awesome core you selected!

To be blunt, plastic is not what you want on a performance intercooler. Plastic end tanks are great for stock vehicles, as failures are pretty minimal … until the vehicle is modified and/or boost levels are increased. These failures are quite common with diesel trucks. A plastic end tank at a mass-produced level is far cheaper and lighter than aluminum options. Automotive manufacturers are seeking both low cost and reduced weight for just about all components on their vehicles; this likely explains why nearly all modern stock and factory vehicles are equipped with plastic tanks.

As you can imagine, plastic will begin to weaken over time as the constant variations of temperature and pressure affect its integrity and lead to eventual failure. This normally occurs in the form of a cracked or shattered end tank during a high-boost pull. When we tested this theory to check the actual pressure capacity of a plastic end-tank equipped intercooler, the result was a nice explosion. Check it out!

Along with complete failure, crimp connections can also spread with constant high boost, and will eventually cause a leak within your system. Within the crimp connection is a rubber gasket, which provides a seal between the aluminum core and the end tank. The crimps fold over on the tank to hold the two components firmly together.

Leaking connections, if small, can go undetected and result in additional wear on your turbocharger and engine. If you have an intercooler with plastic tanks, it may be wise to examine it the next time you perform vehicle maintenance. Leaking areas can usually be identified by oil seepage.

Another benefit of using plastic as a material for end-tank construction is that it is easily shaped and can be designed to provide really efficient flow. Aside from this, stick with an aluminum end tank for a performance-oriented build.

Stamped aluminum end tanks are a bit of a hybrid and incorporate a lower cost (for large manufacturing runs) with the added durability of a one-piece design. These tanks can be found on older turbocharged vehicles, such as the second-generation Cummins and Mitsubishi Evolution, and are typically welded to the actual core.

Intercoolers with stamped end tanks can easily handle high boost pressures; however they are normally paired to a standard tube-and-fin core. Stamped tanks are durable and flow reasonably well, and they are far stronger than their plastic counterparts that eventually replaced them. However, they are not a typical choice (over plastic) for OEM components.

C. Cut-and-Weld Aluminum

To our eyes, a cut-and-weld intercooler tank is shadowed only by a cast-aluminum tank. You could consider the cut-and-weld as a second-best option for your vehicle. By using aluminum and welding this to the core, you eliminate the failure points associated with plastic end tanks. That said, these tanks are typically made from numerous pieces of aluminum, which allows for several potential failure points. Precision welding, proper testing, and efficient quality control processes are necessary to avoid defects with such a design. Typically, a well manufactured piece will provide fantastic durability and should withstand just about any level of boost you throw at it.

As always, there is a downside to this particular style. Being that this tank is constructed from numerous pieces of flat aluminum, it does not allow for much in terms of designing the internal surface. This means that smoothing the airflow is either quite a challenge, or not possible at all.

For most builds, a cut-and-weld tank will certainly do. But why settle for second best?

D. Cast-Aluminum

I certainly don’t want to push you into making a decision, but this is the end tank you want for a build requiring nothing but the best. Combining the best points in reliability and flow, a cast-aluminum end tank is at the top of our list. It has a one-piece aluminum design that is TIG welded to the core of the cooler. Check out a few castings from our 2008–2014 STI intercooler.

This design eliminates failure points from crimp connections, poor welds on a cut-and-weld unit, or blown-out plastic tanks. Thickness of an end tank can vary depending on the pressure requirements; we typically design our tanks with a 4mm wall thickness. This means that you can run any automotive/diesel boost pressure without concern of destroying the tank. If you can manage to do so, however, please send us pictures!

Along with a more robust construction, this tank design allows product engineers to optimize flow. For instance, Mishimoto engineers use CFD software to ensure the tank provides flow to the entire length of the core, dispersing the air to utilize the entire core. This is especially important for intercoolers that are very tall. On top of this, we can even cast air diverters into the internal portion of the tank to push airflow to portions of the core where it would not otherwise reach.

All this innovation results in greater heat transfer. Even if the impact is only the drop of a few degrees in intake temperatures, we find value in spending the time to create a cooler that we know is our best work.

In-short, a cast aluminum end tank is going to be the ideal choice from both an engineering standpoint as well as from a consumer decision-making point.

5. Core Construction (Or, the Value of a Good Core)

Selecting a solid, efficient core is the primary concern when choosing an intercooler for your vehicle. One cooler is not the absolute best for every vehicle. Airflow, boost pressure, and engine displacement will all play a role in how an intercooler has an impact on the performance of your vehicle.

A. Tube-and-Fin vs. Bar-and-Plate

One of the big online discussions regarding intercooler cores is the tube-and-fin vs. bar-and-plate debate. Which do you want? Why is one better than the other? All valid questions here.

Tube-and-fin cores are used on stock intercoolers and are not commonly used for aftermarket units. These coolers are far lighter than the alternative, and are also less expensive to manufacture. (We keep touching on this because it is important to keep in mind when considering why certain components are used by OE manufacturers). The number one reason why tube-and-fin cores are ditched on aftermarket coolers is heat dissipation. Ever heard of heat-soak?

Heat-soak can occur when an intercooler experiences either very warm ambient temperatures, such as a hot engine bay, or repeated pulls that cause the cooler to become overheated. This can then result in power output losses as the ECU adjusts (pulls timing) for the high intake temperatures. Heat-soak is certainly a bad thing. A bar-and-plate intercooler can typically tolerate far more abuse with repeated heating without becoming inefficient. This is especially helpful for vehicles seeing track duty that will be in boost for the better part of longer-duration track lapping. I am talking to you road course guys.

On top of this, a bar-and-plate core is more efficient in transferring heat in general. The design of the bar-and-plate allows for a significantly thinner material containing the airflow, which aids in producing greater heat transfer.

If you are performance driven and not too concerned about adding a few pounds to your vehicle, this is the core style for you. Check out the basic comparison chart below.

For a high percentage of folks paying close attention to intercooler choice, a bar-and-plate design is the go-to and will provide far superior performance in nearly all applications.

B. Fin Styles

Why are these things so complex? I just want an intercooler. Yes, we are getting quite in-depth here, but keep in mind that every single feature of your intercooler is important. We wouldn’t make these recommendations if they weren’t valid. Fins, both internal and external, are available in a few different styles depending on the goals of the cooler itself. For automotive intercoolers, you will typically see either a plain straight fin or an offset-style fin. These are best explained by images.

As you can see, the offset style fin appears to provide far more surface area for air contact. This arrangement will force air to split numerous times on its path through the core, which amplifies the amount of heat exchange that can occur. Along with improving heat transfer, this will also result in greater pressure loss, which is something that you will need to consider. In general, Mishimoto intercoolers utilize an offset fin to enhance the exchange of heat as much as possible.

C. Fin Density

When it comes to intercooler design, fins are a make-or-break component that can make the difference between an efficient cooler and one that belongs in the garbage. As we’ve noted numerous times, more fins equals greater heat exchange; however, this is at the expense of airflow and restriction. Weighing these can be a challenge, but that’s why we have testing and an engineering team.

In general, identifying a dense core is rather simple.

To improve density we can modify both the height and pitch of the fins to create differences in overall fin surface area. We normally create a few prototypes with different variations to put our theories to the test on actual dyno runs.

Fins per inch (FPI) can vary significantly both internally and externally. Both need to be evaluated based on airflow hitting the external surface of the core, as well as airflow moving through the cooler from the turbocharger. Our engineering team uses a variety of equations to come to determine which prototypes will be used for testing. We can then use our data to improve our process for future product development, allowing us to achieve the most accurate results possible.