- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Critical Communication

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

Prevent Workplace Slips, Trips, and Falls—8 Safety Tips

Mopping up a spill or double-checking a guardrail might seem like simple common sense, but slips, trips, and falls are the second most common cause of death at work. These are life-saving procedures. Keep reading for practical tips to prevent workplace accidents.

- Slip, Trip, and Fall Hazards Listed

- Clarifying OSHA Standards

- Prevent Workplace Slips, Trips, and Falls

These are familiar scenarios at home: slipping on a wet floor in the kitchen and tripping over a toy left out by the kids. While annoying, these accidents are typically minor hazards in the home. You might stub your toe, but rarely are there severe consequences.

In the workplace, it’s a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They’re also the second-leading cause of workplace fatalities.

As a safety leader, you’re responsible for your company’s duty of care and for providing a safe workplace . This blog post will examine common hazards leading to slips, trips, and falls and the steps you can take to minimize injury risks for your team.

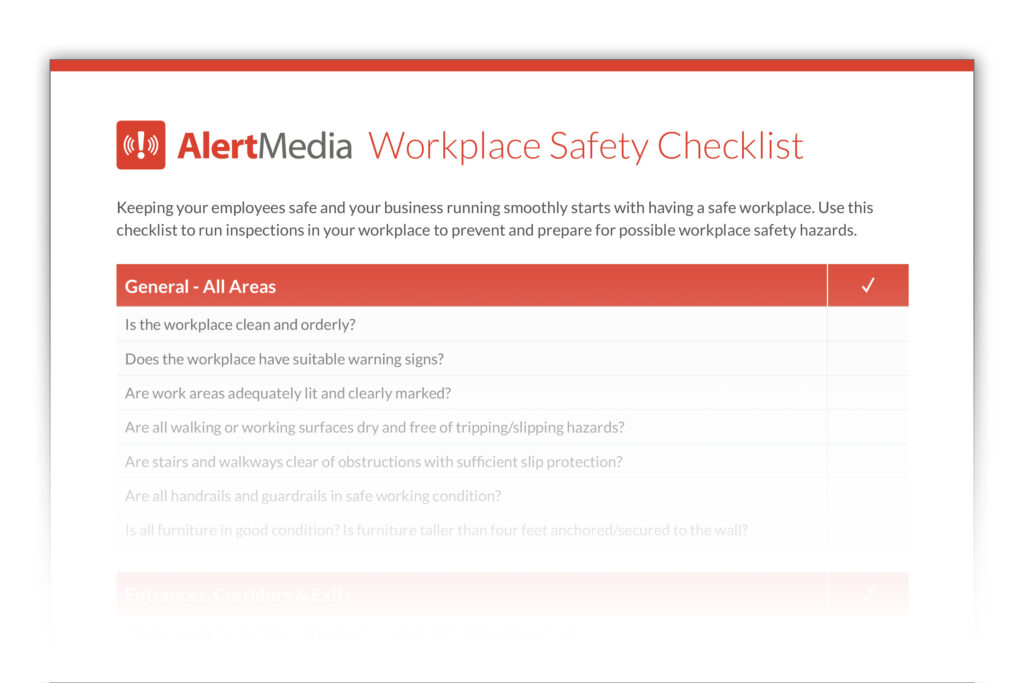

Download Our Workplace Safety Checklist

What are slip, trip, and fall hazards in the workplace.

Accidents involving slips, trips, and falls are often grouped together. While they’re similar, it’s important to understand the distinction since they each have different causes and consequences.

Slips occur when someone’s footwear loses traction with the surface they’re on, causing a loss of balance. Under some circumstances, slipping can lead to a fall.

Trips happen when someone hits their foot or lower leg on an object. As their upper body continues moving forward while their lower body remains stationary, the person may lose their balance in the process.

Falls often result from slips or trips, but they can also happen on their own. For example, a worker on a ladder or scaffolding can lose their balance and fall without slipping or tripping. Falls are also possible on flat surfaces and can still cause serious injuries.

Once you understand the hazards that lead to each type of accident, you can identify and mitigate risks in your workplace. Here are some of the most common causes of slips, trips, and falls in the workplace:

Slip Hazards

- Spills of wet or dry substances

- The cleaning process during spill removal

- Employees rushing or not paying attention to workplace conditions, especially while carrying objects

- Slippery floor surfaces such as marble or laminate

- Wet surfaces

- Poor lighting that obscures hazards

- Inappropriate footwear for the environment

- Transitioning between different types of surfaces

Trip Hazards

- Objects or obstructions in walkways

- Uneven surfaces on flooring or concrete

- Cables, cords, and hoses that aren’t properly secured or organized

- Unmarked steps or ramps

- Irregular stairs or stairs without railings

- Carpet, rugs, or mats with wrinkles or lifted edges

Fall Hazards

- Improperly used or poorly maintained ladders

- Elevated surfaces without guardrails

- Floor and wall openings

- Working in elevated environments without a safety harness

- Ill-fitting or improperly used PPE, such as helmets and safety lines

Preview the Workplace Safety Checklist

Are There OSHA Standards Related to Slips, Trips, and Falls?

Despite how common these injuries are, there is no specific OSHA standard on slips, trips, and falls. However, several OSHA rules indirectly address the same hazards.

The most important regulation to be aware of is 29 CFR 1910 Subpart D, which covers walking and working surfaces. OSHA updated the standard in 2017, introducing many upgrades to fall protection system requirements, improved employer-provided inspection guidelines, and a greater emphasis on safety training for employees.

For the construction industry, 29 CFR 1916 contains numerous fall-related regulations. Subpart M specifically addresses fall prevention, but other sections, such as Subpart L (scaffolds) and Subpart E (personal protective and lifesaving equipment), are also relevant. OSHA used 29 CFR 1916 as guidance when revising 29 CFR 1910, so the two guidelines now reflect many of the same OSHA violations .

As with any other workplace hazard or accident, OSHA recordkeeping requirements still apply in the event of a slip, trip, or fall incident. Internally, the reporting process is also an opportunity to review the details of the incident and determine how you can update your workplace safety policy to prevent similar accidents in the future.

How to Prevent Slips, Trips, and Falls in the Workplace

Many hazards that cause slips, trips, and falls are inevitable. However, injuries and accidents are not. To prevent slips, trips, and falls, train your employees to follow a three-step process:

- Recognize the hazard: Identify conditions that could lead to a slip, trip, or fall.

- Evaluate the hazard: Examine the situation and determine what level of risk it presents and who it affects.

- Control the hazard: Avoid the risk by removing the hazard (such as mopping up a spill) or implementing safety equipment and procedures (such as installing handrails on an elevated platform).

Here are eight workplace safety tips to prevent falls, trips, and slips.

1. Teach situational awareness

Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

- Look at walking surfaces for spills, obstacles, or other potential hazards

- Watch for signage that warns of increased hazards

- Be aware of conditions such as weather or time of day that might increase the risk of an accident

- Take shorter and more cautious steps on slippery surfaces

2. Encourage proper footwear

Like any other form of PPE, proper footwear can significantly reduce the risk of accidents. Research has found that slip-resistant shoes can reduce injury claims by 67% in environments with slippery work surfaces.

Employees should regularly inspect their shoes and make sure the soles aren’t worn out, as the lack of tread increases the danger of slipping. Additionally, anyone who works in conditions exposed to winter weather hazards should wear insulated boots. Cold temperatures can decrease muscle function, increasing the risk of slipping, tripping, or falling.

3. Utilize signage

Signage is an effective warning system for many workplace risks, but it can be especially effective in preventing slips, trips, and falls. There are two types of signs you can use to increase occupational safety:

- Temporary: Use warning signs while addressing a new hazard, such as cleaning up a spill, repairing a handrail, or replacing a ripped carpet. While temporary signage can help prevent injuries, you still need to address the actual hazard as quickly as possible.

- Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it’s easy for people to ignore signs they see every day.

4. Keep floors clear and clean

Good housekeeping can help prevent most slips, trips, and falls. The details of keeping walking areas clean will vary widely by work environment, but there are a few common themes to encourage workplace safety:

- Report spills immediately, and warn nearby employees until someone can clean the contaminated surface

- Keep walkways clear of obstacles, loose objects, and anything that someone could trip over

- Place mats at entrances and exits so people can dry their shoes and avoid tracking water or other substances around the workplace

- Install handrails on stairways and elevated walkways

5. Apply non-slip mats and coatings

In some situations, keeping floors from becoming slippery is nearly impossible. Whether it’s liquid splashing or steam condensing, you must focus on mitigating the risk rather than avoiding it altogether.

For smaller or less demanding settings, non-slip mats can help employees maintain traction while walking around. In other cases, treating the floor with a permanent coating can help reduce slipping risks, even in the constant presence of liquids.

Who is at risk for slips, trips, and falls?

While all industries have some level of risk for a slip, trip, or fall, there are some industries where the risk is much higher, and the potential result could be much more dangerous. Here are some of the highest-risk industries:

- Construction

- Manufacturing

- Transportation/shipping/logistics

- Outdoor maintenance/groundskeeping

- Foodservice/hospitality

6. Ensure proper lighting

To identify slip, trip, and fall hazards, your employees need to be able to see their surroundings. Make sure that all of your work areas have proper lighting, especially in areas that are more prone to unsafe conditions.

While this can be a challenge in outdoor work environments, especially at night, it’s even more critical in those situations. Environmental conditions can lead to increased risks, and employees need to be able to see and avoid them. Adequate lighting should also extend to parking lots and walking areas around your facilities.

7. Develop safety programs

Your company’s safety plans and programs should include specific guidelines for preventing slips, trips, and falls. There are a few key topics to consider when developing these policies:

- The types of surfaces employees work and walk on and whether they present extra risks

- Seasonal or regional conditions that could heighten hazards, such as winter weather threats

- Specific OSHA regulations that apply to your workplace

- Potentially hazardous equipment training such as ladder safety

- Regular inspection plans to ensure your team is maintaining a safe work environment

- Policies to report hazards using your company’s two-way communication platform

- First aid training , so employees are prepared to respond safely should injuries occur

8. Provide Slips, Trips, and Falls Training

Lastly, training your employees to avoid slips, trips, and falls will help keep them safe. Provide specific guidance on the environments they’ll work in and the hazards they’ll face. For example, a slips, trips, and falls safety talk for food service workers should focus on wet floors and walking safely in crowded, fast-paced environments. Conversely, office workers could use extra reminders to watch for stray power cords and keep walkways clear of boxes, files, and other tripping hazards.

Working slips, trips, and falls into your safety topics for meetings is also helpful. Regular safety talks or safety moments are an excellent opportunity to remind your team about seasonal risks or update them on newly installed safety measures.

Don’t Let Your Safety Standards Slip

Slips, trips, and falls are some of the most common workplace injuries. Fortunately, you can usually prevent them with proper planning and safety measures.

By making slip, trip, and fall prevention a part of your company’s safety culture, you can ensure your employees are aware of their surroundings and ready to look out for each other’s safety. Enable them to report hazards easily, address risks quickly, and train them to avoid situations that are likely to cause injury.

With the right planning and prevention, even the most intense work environments can be as safe as a walk in the park.

More Articles You May Be Interested In

Workplace Safety Checklist

Please complete the form below to receive this resource.

Check Your Inbox!

The document you requested has been sent to your provided email address.

Cookies are required to play this video.

Click the blue shield icon on the bottom left of your screen to edit your cookie preferences.

Posted on: February 22, 2023

Slips, Trips, and Falls: Preventing Workplace Trip Hazards

When you think of a workplace accident, you probably think of something dramatic – an explosion or an amputation, for example.

But the second-most common cause of workplace injury is a trip or slip hazard that leads to a fall. And 20-30% of workplace falls result in a moderate or severe injury like deep bruising, broken bones, or concussions.

In fact, according to OSHA, slips, trips, and falls cause nearly 700 workplace fatalities per year – that's 15% of all workplace deaths.

The trouble is that the circumstances that lead to slips and trips tend to be spontaneous and changeable – they don't exist until suddenly they do. That means preventing slips, trips, and falls is an ongoing process that relies heavily on employees being able to recognize related hazards.

What Are OSHA's Trip Hazard Regulations?

OSHA's primary standard for slip, trip, and fall hazards is the General Industry Walking-Working Surface standard (29 CFR 1910 Subpart D, which includes §1910.21-30).

Related Construction Industry standards are scattered throughout §1926, including Subparts C, L, M, and X. However, OSHA's 2017 slip, trip, and fall revisions aligned Construction standards with General Industry wherever possible.

Finally, some specific slip, trip, and fall OSHA regulations ensure a safe exit route from any workplace. After all, the last thing you want during an emergency evacuation is a bottleneck at the exit. These Means of Egress regulations are found under §1910.36-37.

Walking and Working Surfaces

Definitions related to slips, trips, and falls.

The temporary nature of an OSHA tripping hazard makes a clear set of definitions even more critical.

What is a Walking-Working Surface?

When you first see the name of OSHA's main trip and slip hazard, you may wonder what a "walking-working surface" is.

But it's just a surface you walk on…or work on. Walking-working surfaces include floors, aisles, stairs, platforms, and more.

Slips vs. Trips

Slips and trips can lead to falls, but there's a pretty clear distinction between the two.

A slip happens when there's insufficient traction between your foot and the walking-working surface, causing a sudden loss of balance.

A trip happens when your leg or foot comes into contact with a hazard (either an object or an uneven surface) that arrests the movement of your lower body while momentum carries your upper body forward.

What are the Two Types of Falls?

A fall happens when your center of gravity shifts unexpectedly, but for workplace safety purposes, falls are divided into two different categories: same-level falls and elevated falls.

An elevated fall is when someone falls from one level to another, like from a ladder, scaffold, building, or through an opening in the floor.

A same-level fall is when someone falls to the floor they're standing on or against a nearby object or wall.

What are Examples of Slipping and Tripping Hazards?

There are many factors that can contribute to the likelihood of a slip or trip. Many slip or trip hazards are substances or objects that make a walking-working surface dangerous, but footwear and environmental conditions also play a part.

Examples of Slip Hazards

Basically, anything that decreases the amount of friction between your foot and the walking surface increases the risk of slipping.

This includes:

- Water, ice, snow, mud, grease, oil, food, or other wet products on smooth floors

- Dust, powders, plastic wrapping, granules, or other dry products that are slippery on smooth floors

- Freshly waxed surfaces

- Highly polished surfaces that remain slick when dry (like concrete, marble, or ceramic)

- Loose or irregular surfaces like gravel or unanchored flooring

- Sloped walking surfaces without slip- or skid-resistance

- Muddy terrain

- Wet or dry leaves, pine needles, or plant debris

- Shoes with inadequate traction

- Soles that are wet, muddy, or greasy

As you can see, slip hazards can be found indoors or outdoors.

Workplace Trip Hazard Examples

Officially, OSHA's trip hazard height is a quarter inch. Any change in floor level that is ¼ inch or more constitutes a tripping hazard.

Examples of common tripping hazards include:

- Uncovered hoses, cables, wires, or cords across walking surfaces

- Obstacles or clutter on walking surfaces

- Furniture drawers/door left open

- Unmarked steps or ramps

- Damaged or irregular steps

- Rumpled carpets or mats (or curled edges)

- Thresholds, gaps, and other irregularities in walking surfaces

- Speed bumps and curb drops

Other factors can also contribute to the likelihood that you'll trip, including lack of coordination or an obstructed view of the walking surface. Many circumstances can contribute, including:

- Being under the influence

- Poor air quality

- Poor lighting

- Bulky loads

- Poor vision

Slips, Trips, and Falls Prevention

Some slip, trip, and fall prevention measures are permanent, including:

- Adequate lighting

- Slip-resistant surfaces in high-risk areas

- Effective drainage, ventilation, and other methods to keep surfaces dry

- Marking the edges of steps or elevation changes

Other methods for preventing slips, trips, and falls require ongoing participation from workers, including:

- Proper footwear

- Safe work practices

- Frequent cleaning

- Good housekeeping practices that keep walkways free of clutter

- Noticing and marking slip or trip hazards

As a result, a lot of slip, trip, and fall prevention relies on the ability of your workforce to recognize slipping and tripping hazards, understand how to mitigate them, and know how to use safe work practices to minimize their risk.

Even though there's no formal OSHA requirement for Slip, Trip, and Fall training, workers need education and regular refreshers in OSHA trip hazards and regulations to accomplish all of this correctly.

One of the easiest and most effective ways to keep your workforce fresh on this topic is to use online courses from an OSHA-authorized training provider like us. We have a Walking and Working Surface course that your employees can take at their own convenience and pace. Get started today!

OSHA Group Training Enrollment

Need to train your employees? Sign up today to set up a business account with OSHA.com. We offer an enhanced Learning Management System (LMS) and special discounts for large orders.

Group Enrollment Application

Indeed.com rating, trusted by industry leaders.

"The support team really helped me out! I really needed to get this training done for work and they definitely helped make it happen! Best support group I’ve ever dealt with! Thanks again!"

More testimonials

We’re getting your search results.

- Customer support

- Customer login

- Report a claim

- Find an agent

- Roadside assistance

- Manage policy

- Hanover Mobile

- Choose paperless

- Education and training

- The Hanover Risk Solutions

- Sickness prevention center

- Preparation and prevention

- Coverage made clear

- Claims made clear

- Partners in Protection

- Media contacts

- Login to TAP

- Personal lines

- Commercial lines

- Resource library

- Become an agent

- Investors overview

- Statutory results

- Annual reports

- Event calendar

- Historical prices

- Presentations

- Press releases

- Quarterly results

- Stock quote

- ESG overview

- Inclusion and diversity

- Sustainability report

- Early in career opportunities

- Forgot username

- Forgot password

- Create an account

- Report a claim without logging in

- Individuals

- About The Hanover

- I'm looking to...

- Adding a new driver

- Buying a first motorcycle

- Moving out and moving up

- Ready for retirement

- Updating your home

- Buying a boat

- Buying a home

- Buying or selling a car

- Getting married

- Starting a family

- Recreational vehicles

- Condominium

- Home business

- Valuable items

- Hanover Platinum

- Hanover Prestige

- Get a quote from a local agent

- Manage my policy

- Manage my account

- Water damage prevention

- Construction

- Cultural institutions

- Educational institutions

- Financial institutions

- Human services

- Life sciences

- Manufacturers

- Professional services

- Real estate

- Wholesalers

- Business owner's policy

- General liability

- International

- Management liability

- Professional liability

- Workers' compensation

- Customer onboarding

- About Hanover claims

- Claims resources and FAQs

- Reviews and testimonials

- Workers' compensation claims resources

- What to expect with your claim

- Prepare now. Learn how.

- Weather resource center

- Our companies

- Our history

- Our leadership

- Board of directors

- Our governance

- Our locations

- Sustainability

- Inclusion, diversity and equity

- Recognitions and awards

- Global reporting initiative index

- Community impact

- News releases

- In the media

- Find out what coverage I need

- Explore insurance products

- Save with bundled coverages

- Contact an agent for a quote

- Learn about The Hanover

- Find out what coverage my business needs

- Pay my bill

- File a claim

- Talk to an agent

- Get roadside assistance

- Sign up for paperless

- Set up Hanover mobile

- Print ID card

- Get tips on preparedness

- Agent Solutions

- Discover employee benefits

- Look for a job

- See our locations

Sample slip, trip and fall prevention program

This sample program is intended to provide general information to consider in developing a slip, trip and fall prevention program. This sample program may or may not represent all components of a slip, trip and fall safety program needed by your unique operations or comply with all legal requirements and/or standards. You are responsible for tailoring the program to address the specific needs of your organization.

Table of Contents

- Introduction

- Sample policy statement

- Housekeeping standards

- Seasonal issues

- Corrective maintenance procedure

- Workplace inspection policy and procedure

- Responsibilities

- Safety rules

- Accident investigation procedure

- Additional tools and resources

- Appendix A periodic inspection report Appendix B sweeping log

- Appendix C walking and working surfaces — self inspection checklist Appendix D accident investigation report

- Appendix E snow and ice control record

1. Introduction

Nationally, falls are the second leading cause of accidental death and a major cause of debilitating injuries. This program is designed to reduce exposure to both visitor and employee slip, trip and fall accidents.

2. Sample policy statement

The most effective safety program policy statements reflect your unique operations and environment. Here is a sample:

“It is the policy of ABC, Inc. to provide our employees and customers safe and healthful conditions in which they can conduct business. We will strive to maintain a facility that is free from identified slip, trip and fall hazards. We have implemented a prevention program that considers the behaviors of people, our equipment, our work methods, processes and finally the environment to reduce and prevent slip, trip and fall accidents. We expect all employees to cooperate in this very important initiative to ensure its success.”

3. Training

Management believes that employee involvement in the site’s safety and health program can only be successful when everyone on the site receives sufficient training to understand what their safety responsibilities and opportunities are, and how to fulfill them. Therefore, training is a high priority to help ensure a safe workplace.

All employees will receive awareness training during orientation. Employees who conduct formal workplace inspections will be trained on their responsibilities and on how to perform them.

4. Housekeeping standards

Housekeeping plays such a critical role in the success of our slip, trip and fall prevention program that all employees must make housekeeping their top priority. The following are minimum accepted guidelines:

- Work areas are to be kept clean throughout your shift and a thorough review and cleaning must be completed prior to leaving your shift.

- Walkways will be kept clear of electric cords, hoses or any other potential hazards. If walkways cannot be kept clear then they need to be blocked off until the task is completed.

- Spill areas must be secured until the spill is removed.

- Stock or finished goods will not be stored on stairs, in walkways or in such a manner that would be a hazard to anyone walking through.

5. Seasonal issues

The changing seasons create unique weather-related conditions for which the following procedures have been developed:

- All building entrances will be cleaned of snow and ice, and will be treated with salt, one hour prior to the opening of business.

- Exterior walkways will be inspected hourly and treated as needed.

- Use the form “Snow and Ice Control Record” found in Appendix E to document the work.

- Parking lots will be inspected daily. Any snow or ice that has accumulated between cars will need to be removed.

- During the fall, daily inspections will be made and action taken as needed to ensure walkways are cleared of leaves.

6. Corrective maintenance procedure

When a hazard has been identified through inspection or our hazard reporting program, maintenance must be notified so that the problem can be corrected. The following is the procedure to accomplish this task:

- Any problem needs to be communicated to the manager immediately.

- The maintenance manager will inspect the problem and communicate the best action to take.

- If it can’t be corrected immediately, a temporary control will be put in place to prevent anyone from being injured.

7. Workplace inspection policy and procedure

Our goal is to ensure a safe, clean and hazard free environment for employees and customers. Workplace inspections will be conducted to identify and correct potential safety and health hazards.

Use our “Walking and Working Surfaces — Self Inspection Checklist” found in Appendix C to document the inspection.

- Inspections will be carried out by supervisors of their functional areas. The manager will inspect common areas and all outside areas including the parking lot.

- Any deficiencies or hazards must be acted upon to remove the hazard, warn of it or close off the area in question.

Three types of inspections are used to assess our facility. Each type of inspection has its own purpose.

Annual inspections

Once a year an inspection team made up of representatives of the organization will do a wall-to-wall walk through inspection of the entire worksite. They will use the “Walking and Working Surfaces — Self Inspection Checklist” found in Appendix C. The results of this inspection will be used to:

- Eliminate or control obvious hazards.

- Target specific work areas for more intensive investigation.

- Assist in revising the checklists used during periodic safety inspections.

- Evaluate the effectiveness of our slip, trip and fall prevention program.

Change of operations surveys

Changes include new equipment, changes to production processes or a change to the building structure or premises. Examine the changed conditions and make recommendations to eliminate or control any hazards that were or may be created as a result of the change. This needs to be comple ted during the design stage of any proposed changes to ensure recommendations are incorporated into the changes. The “Walking and Working Surfaces— Self Inspection Checklist” found in Appendix C can be used as a guide for this survey.

Periodic safety inspections

Supervisors or their appointees will inspect their work areas for hazards using the “Walking Surfaces Periodic Inspection Checklist.” The results of the periodic inspection and any action taken will be documented.

8. Responsibilities

It’s important that all employees understand their responsibilities. The following are some examples that can be tailored to fit your organization’s management structure.

Management responsibilities

- Ensure that sufficient employee time, supervisor support and funds are budgeted for safety equipment, training and to carry out the safety program.

- Evaluate supervisors each year to make sure they are carrying out their responsibilities as described in this program.

- Ensure that incidents are fully investigated and corrective action taken to prevent the hazardous conditions from developing again.

- Set a good example by following established safety rules and attending required training.

Supervisor responsibilities

- Supervisors must assure this program is adhered to and that all employees follow program policies and procedures.

- Ensure that each employee you supervise has received an initial orientation before beginning work.

- Observe the employees as they work. Promptly correct any unsafe behavior.

- Do a daily walk-around safety-check of the work area and promptly correct any hazards you find.

- Set a good example for employees by following safety rules and attending required training.

- Investigate all incidents in your area and report your findings to management.

- Talk to management about changes to work practices or equipment that will improve employee safety.

Employee Responsibilities

- Clean up spills and pick up debris to help ensure others are not injured on company property

- Report hazards to supervisors or managers promptly for corrective action.

- Follow safety rules, safety standards and training you receive as described in this program

- Report all injuries and near miss incidents to your supervisor promptly regardless of how serious.

- Make suggestions to your supervisor or management about changes you believe will improve employee safety.

Maintenance/engineering

- Must purchase waxes with non-skid characteristic and do not decrease the coefficient of friction of floor surfaces.

- Review floor cleaner data sheets to assure that no slippery floors are created.

- Must integrate the stair design requirements, uniformity of risers, and tread principles, ramp requirements and slope considerations into building design, and building modifications as appropriate.

Facility safety

- Will inspect buildings for hazards and inform maintenance and/or housekeeping of hazards that are identified.

- Will supply deicer in buckets along with scoops at building entrances during inclement weather.

- Check floor surfaces as requested for slip or trip hazards, determine any needed corrective action and notify appropriate party to correct the problem.

Housekeeping

- Must use barricades when the floor they are working on is slippery or presents a tripping hazard. Barricades will be removed as soon as the hazard is corrected.

- Place non-skid mats at building entrances during inclement weather. Inspect mats periodically or as needed to ensure they are properly controlling the hazard.

9. Safety rules

The following basic safety rules have been established to control slip, trip and fall accidents. These rules are in addition to safety rules that must be followed when doing particular jobs or operating certain equipment. Failure to comply with these rules will result in disciplinary action.

- Always take the proper safety precautions before doing a job. If a job is unsafe, report it to your supervisor. We will find a safer way to do that job.

- Horseplay, running and fighting are prohibited.

- Clean up spills immediately. Replace all tools and supplies after use.

- Keep tools or materials out of designated walkways.

- Protect all spill areas. If needed, get someone to help clean up the spill or guard the spill while you get the necessary equipment to clean the spill.

- If you see a slip or trip hazard do something about it. It’s the responsibility of everyone to identify and control hazards.

- Make sure scraps don’t accumulate where they will become a hazard. Good housekeeping helps prevent injuries.

Proper footwear is an important component of our slip, trip and fall prevention program. Footwear needs to be appropriate for the task. In many of the work areas other than our offices, high heeled shoes and leather soled shoes are considered unsafe and must be avoided. It is the responsibility of each employee to obtain and maintain slip resistant footwear in a serviceable condition. Supervisors will ensure that employees are wearing appropriate slip resistant footwear at all times in the workplace.

Mats and Runners

Our goal is to maintain all floor surfaces in a slip resistant condition. In those work areas or situations where this isn’t feasible, mats or runners will be used to provide slip resistance. It is everyone’s responsibility to monitor mats and runners to ensure they continue to provide proper slip resistance and have not become a tripping hazard.

Where mats have been used to control wet areas, either entry ways to the building or wet processes, the following conditions require immediate action:

- If pedestrian traffic leaves wet foot prints when stepping off the mat, the mat needs to be replaced with a dry one or an additional mat needs to be placed at the end of the first mat.

- If the mat has become wrinkled or bunched up it needs to be reset so it is flat and doesn’t present a tripping hazard.

10. Accident investigation procedure

All accidents will be investigated and analyzed to identify the root cause. The following steps will be taken when an accident occurs.

- Helping the injured person will be the primary concern immediately following an accident. Never leave the person alone. If assistance is needed send someone else or have someone stay with the person while you get help.

- If the injured party is not an employee, do not admit liability or fault for the accident. If they ask if we are going to pay for their medical costs simply state that someone from The Hanover Insurance Group will be in touch with them.

- Protect the accident scene to prevent anyone else from getting hurt and to preserve the accident scene in an “as is” condition to help ensure an accurate investigation.

- Contact the supervisor of the area where the accident occurred so they can begin the collection of data and accident analysis.

- The information will be collected and the analysis completed using our “Accident Investigation Report.”

- Photos need to be taken of the general area, any defective conditions and anything else that could be considered as a contributing factor of the accident.

- Once the root cause is determined, corrective action will be initiated immediately following standard procedure.

11. Additional tools and resources

The following resources are available to help in the development of your slip, trip and fall prevention program. They can be found on www.hanoverrisksolutions.com .

Loss Control Topics

- Preventing Restaurant Employee Slips and Falls

- Sidewalk Inspection Checklist

- Parking Lot Safety

- CPSC Tips for Public Playground Safety

- Fall Prevention Checklist

- NIOSH Slip, trip and fall prevention in the healthcare industry

To learn more about Hanover Risk Solutions, visit hanoverrisksolutions.com

171-0954 (3/16) LC 11-187

12. Periodic inspection report

Modify this form to meet the unique characteristics of your facility. The items listed are a guide and may not include all your possible hazards.

171-0954 (3/14) LC 11-187

Sweeping log

An entry is to be made on this log every time the floor is swept or is observed to be free of foreign material. Sign you name and indicate the time of the observation or cleaning.

171-0954 (3/14) LC 11-187

13. Walking and working surfaces — self-inspection checklist

Slips, trips, and falls constitute the majority of general industry accidents. The Occupational Safety and Health Administration’s (OSHA) standards for walking and working surfaces apply to all permanent places of employment, except where only domestic, mining, or agricultural work is performed. This “self-inspection” checklist, developed from OSHA guidance, can be used by supervisors to create a safer work environment.

171-1083 (02/14) LC 10-265 H June 2010

Sample accident investigation form

Accident information.

Date of accident: __________________________________ Date of report: _______________________________________

Where did the accident occur? ___________________________________________________________________________

Time of accident: __________________

Name(s) of injured: ____________________________________________________________________________________

Are these company employee(s)?

Contractors?

Names of non-company individuals (if applicable): ____________________________________________________________

____________________________________________________________________________________________________

Occupation of employee(s): _____________________________________________________________________________

Witnesses to accident: _________________________________________________________________________________

Description of any property damage: ______________________________________________________________________

___________________________________________________________________________________________________

Description of events: __________________________________________________________________________________

Contributing factors

Act(s) (describe): ______________________________________________________________________________________

Conditions (describe): __________________________________________________________________________________

Root cause(s) of accident: _______________________________________________________________________________

Corrective actions to take

(Describe what actions need to be taken to prevent a reoccurrence)

Report developed by:____________________________________Dept.: ____________________________________

Report reviewed by:_____________________________________ Date:_____________________________________

171-0830 (1/14) LC 12‐169

14. Snow and ice control record

PAGE __________

Instructions: Use this log to document efforts to maintain walking and driving surfaces during winter weather. Keeping completed records may improve your defense position in the event of an incident.

This material is provided for informational purposes only and does not provide any coverage or guarantee loss prevention. The examples in this material are provided as hypothetical and for illustration purposes only. The Hanover Insurance Company and its affiliates and subsidiaries (“The Hanover”) specifically disclaim any warranty or representation that acceptance of any recommendations contained herein will make any premises, or operation safe or in compliance with any law or regulation. By providing this information to you, The Hanover does not assume (and specifically disclaims) any duty, undertaking or responsibility to you. The decision to accept or implement any recommendation(s) or advice contained in this material must be made by you.

171-0878 (1/15) LC 09-444 H

Slip, Trip, and Fall Prevention for Healthcare Workers

December 2010, dhhs (niosh) publication number 2011-123.

According to the U.S. Bureau of Labor Statistics [2009], the incidence rate of lost-workday injuries from slips, trips, and falls (STFs) on the same level in hospitals was 38.2 per 10,000 employees, which was 90% greater than the average rate for all other private industries combined (20.1 per 10,000 employees). STFs as a whole are the second most common cause of lost-workday injuries in hospitals.

Slip, Trip, and Fall Prevention for Healthcare Workers [PDF 979.73KB]

Follow NIOSH

Niosh homepage.

- Workplace Safety & Health Topics

- Publications and Products

- Contact NIOSH

Exit Notification / Disclaimer Policy

- The Centers for Disease Control and Prevention (CDC) cannot attest to the accuracy of a non-federal website.

- Linking to a non-federal website does not constitute an endorsement by CDC or any of its employees of the sponsors or the information and products presented on the website.

- You will be subject to the destination website's privacy policy when you follow the link.

- CDC is not responsible for Section 508 compliance (accessibility) on other federal or private website.

- Search search

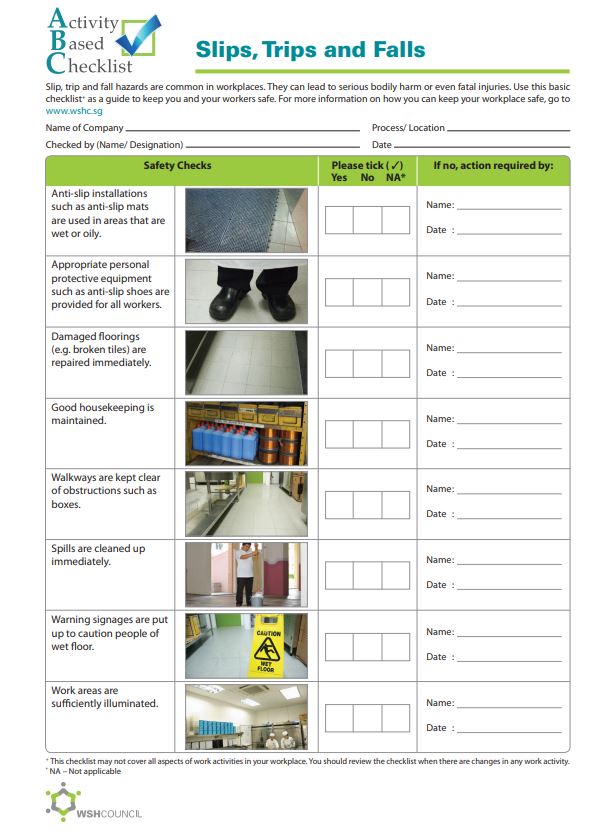

- Slips Trips and Falls Checklist

Slips, Trips and Falls Checklist

06 Sep 2013 Publications Checklists and Articles English , Mandarin Kitchen Safety , Slips, Trips and Falls

File size: 0.95mb

Advisory – Beware of scams and phishing emails

Send us feedback if you receive any suspicious or inappropriate emails asking for your personal information. The email may not have been sent by Workplace Safety and Health Council. Do not click on any link or open any attachments. Your feedback can help us fight against scammers – contact us immediately. We use cookies on wshc.sg to provide a better user experience that's more tailored to you. If you continue, you are giving us your consent to receive cookies only on this site. To decline cookies at any time, simply adjust your browser settings. Read our Privacy Statement.

Slips,Trips and Falls checklist

- by khaled Ismail

- April 16, 2017

Prevention of Slips, Trips, and Falls is major point of emphasis for employers across a wide range of industrial classifications.

That’s because injuries in this category result in 15% of all accidental deaths and are the second leading cause of fatalities, behind motor vehicle accidents.

Use this simple checklist to audit potential problem areas for common slip, trip, and fall hazards in your working environments.

you can use the following sample of Slips, trips and fall checklist and change it to be fit with your company

For more HSE forms CLICK HERE

khaled Ismail

- Pingback: Slip, Trip, and Fall Prevention for Healthcare Workers HSSE WORLD

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Lift Plan Form

Emergency drill table top meeting form, you may also like.

Tool Box Talk: Working Around Heavy Equipment

- January 7, 2022

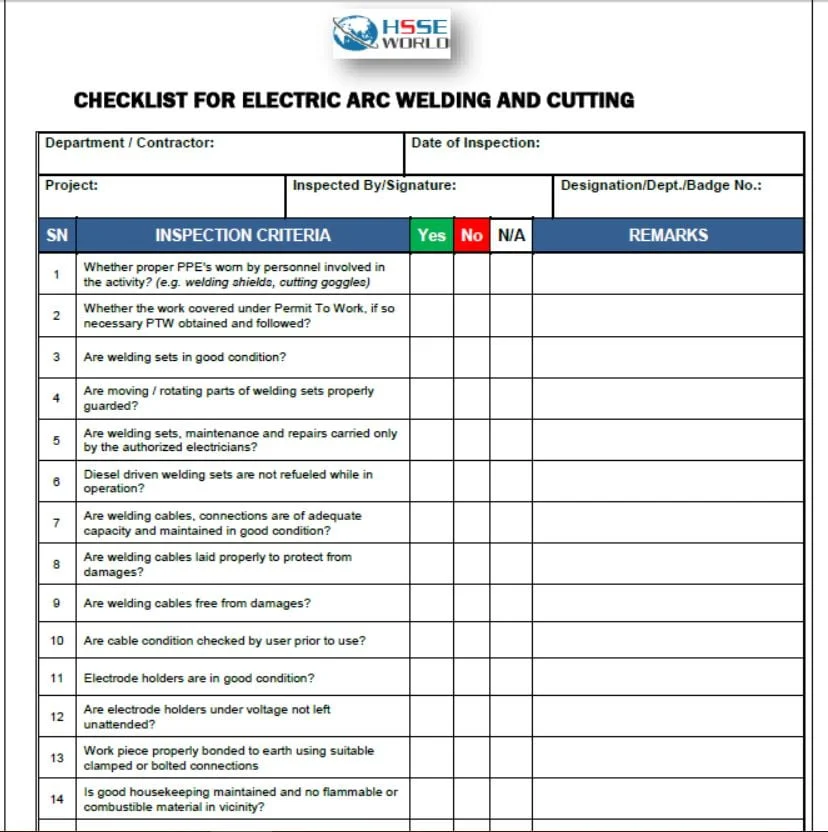

Electric Arc Welding and Cutting Checklist

- April 20, 2019

Privacy Overview

COMMENTS

SLIP TRIP AND FALL PREVENTION CHECKLIST. LIP, TRIP AND FALL PREVENTION CHECKLISTUse the checklist below to determine if there are slip, tri. and/or fall hazards in your workplace. If you answer "yes" to any of the questions below there may be a slip, trip or. are sloped 2% for proper drainagePedestrian pathways through landscaping are.

Slips, Trips, and Falls Inspection Checklist . Slips, trips and falls are one of the most common safety incidents in all workplaces. Although it may not seem like workers can get seriously injured by, say, falling over an extension cord, the fact is that injuries suffered in slips, trips and falls account for many workplace injuries. Tailor ...

G SLIPS, TRIPS AND FALLS CHECKLISTRememberRisk factors include physical hazards in the environment, age-related issues and health conditions. Reduce your risk and identify fall hazards in your workplace and ho. National Safety Council. tasca, il 60143-3201(800) 621-7619nsc.orgMany people attribute falls to being clumsy or not pa.

Slip, Trip, Fall Prevention Safety Checklist . Page 1 of 3 . This checklist is organized around some of the most common causes of slip/trip/falls within a healthcare organization. The purpose of this checklist is to enhance Safety Officer rounds within a facility by calling attention to the most common hazards. Interior Floors. Yes No Notes

CAHF QI Subcommittee 2016 Slip, Trip, and Fall Prevention Slips, Trips, and Falls Checklist Read each statement and place a check mark in the box indicating either Yes or No. If a check mark falls in a red-shaded box, that indicates a hazardous condition may be present and needs further attention. Slip, Trip, and Fall Environmental Hazard ...

Checklist memers et oe Slips, trips and falls are the No. 2 cause of nonfatal disabling injury in the workplace following overexertion. Fortunately, by being aware of our surroundings, slips, trips and falls are easily preventable. ... Wear slip-resistant footwear if needed Focus on problem areas; inspect these areas on a regular basis ...

Checklist for Improved Slips, Trips and Falls Safety Take the time to review your current safety program and ensure that you have the right practices, products, training, response plans and reporting steps in place to help prevent slips, trips and falls. This checklist will guide you, each step of the way!

This checklist has been developed to assist in the identification of slips, trips and fall hazards in departmental environments. It is recommended that this checklist be completed as least once a year or when slip, trip and fall hazards have been identified. After completing the checklist consult with your Health and safety advisor (HSA) and/or ...

Slips, Trips & Falls Inspection Checklist . Slips, trips and falls are one of the most common safety incidents in all workplaces. Although it may not seem like workers can get seriously injured by, say, falling over an extension cord, the fact is that injuries suffered in slips, trips and falls account for many workplace injuries. According to ...

Prevention of Slips, Trips, and Falls is major point of emphasis for employers across a wide range of industrial classifications. That's because injuries in this category result in 15% of all accidental deaths and are the second leading cause of fatalities, behind motor vehicle accidents. The Occupational Safety & Health Administration (OSHA ...

This checklist is designed to manage the risks of injury due to slips, trips and falls. How to use this worksheet Follow the worksheet step by step and refer to the guidance provided after each question on the worksheet to: • Assess the risks associated with slips, trips and potential falls from elevations less than four feet high.

incidence of slips, trips and falls. The following proactive measures are largely excerpted from a checklist developed by the National Floor Safety Institute located in Bedford, TX, entitled "OSHA Self-Inspection Checklist—Walking and Working Surface Requirements" and are designed to help minimize slip and fall incidents. Housekeeping

Slips, trips, and falls cause nearly 700 fatalities per year and many more injurious accident in the workplace according to the Bureau of Labor Statistics. There are three physical factors involved in slips, trips, and falls: friction, momentum, and gravity. Each one plays a role. Friction is the resistance between objects, momentum is affected ...

Slip, Trip and Fall Prevention Checklist CHAPTER 7 35 Conclusion John understands what just one slip can mean for a facility. As an environmental ... This slips, trips and falls guidebook was created to not only give you a better explanation of what this common workplace safety offender is all about, but to

Slip, Trip, Fall Inspection Checklist Inspector: _____Date:_____ Provide written comments on back for all items checked No. Area / Item Yes No N/A Parking Lots Well illuminated Free from potholes or disturbed asphalt Vehicle parking is properly marked Curbing and speed bumps are brightly colored ...

In the workplace, it's a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They're also the second-leading cause of workplace fatalities.

Making sure proper footwear is worn - Non-slip shoes with good traction protect workers from static electricity, falling objects, explosions, exposure to hazardous substances, and other risks. Maintaining and improving floor quality - Modifying the floor space can go a long way to ensure safety from slips, trips, and falls.

Slips, Trips, and Falls Prevention. Some slip, trip, and fall prevention measures are permanent, including: Adequate lighting. Handrails. Slip-resistant surfaces in high-risk areas. Effective drainage, ventilation, and other methods to keep surfaces dry. Marking the edges of steps or elevation changes.

View and download Slips, Trips, and Falls Checklist for free. Browse the public library of over 100,000 free editable checklists for all industries.

Walking and working surfaces — self-inspection checklist. Slips, trips, and falls constitute the majority of general industry accidents. The Occupational Safety and Health Administration's (OSHA) standards for walking and working surfaces apply to all permanent places of employment, except where only domestic, mining, or agricultural work ...

Slip, Trip, and Fall Prevention for Healthcare Workers. According to the U.S. Bureau of Labor Statistics [2009], the incidence rate of lost-workday injuries from slips, trips, and falls (STFs) on the same level in hospitals was 38.2 per 10,000 employees, which was 90% greater than the average rate for all other private industries combined (20.1 ...

Slips, Trips and Falls Checklist. 06 Sep 2013 Publications Checklists and Articles English , Mandarin Kitchen Safety , Slips, Trips and Falls. Download Publication. File size: 0.95mb.

Prevention of Slips, Trips, and Falls is major point of emphasis for employers across a wide range of industrial classifications. That's because injuries in this category result in 15% of all accidental deaths and are the second leading cause of fatalities, behind motor vehicle accidents. Use this simple checklist to audit potential problem ...