- Free Practice Tests

Commercial Driving

- Introduction

Getting a CDL

- Fees and costs

CDL Types & Permits

Endorsements & Restrictions

CDL Exam Preparation

Written exams

Practical exams

- Skills test

- Pre-trip inspection

- TSA background check

- Retake policy

CDL Maintenance

ELDT Training & Certification

CDL how-to guides

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

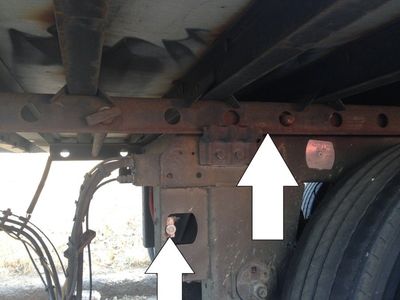

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

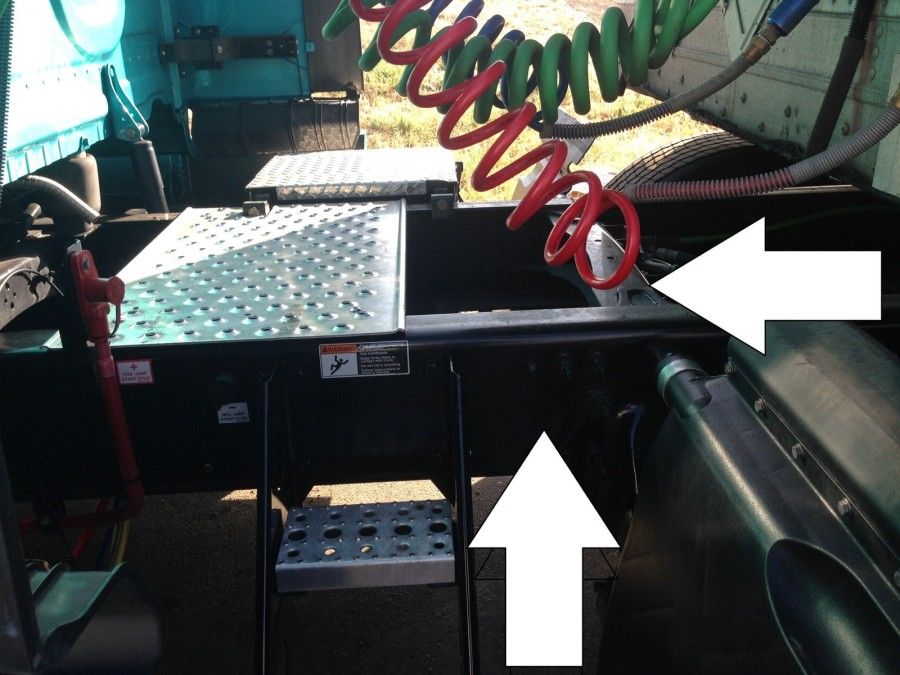

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

- Why Whip Around

- Maintenance

- Inspections

- Reporting & Analytics

- Fuel Management

- Integrations

- Executive/Owner

- Fleet Manager

- Case Studies

- Our Story & Leadership

Pre-trip Inspection Guide: Class B Commercial Driver Licenses

Table of contents.

There are numerous aspects that go into a pre-trip inspection depending on the class of commercial driver’s license obtained. Having a CDL or operating a fleet is a responsibility, therefore, it is critical to be educated on the different types of classes for CDL inspections to be fully prepared. There are specific pre-trip inspections that need to be completed in order to successfully operate a Class B vehicle. Knowledge is power in the fleet industry and forgetting important details can be consequential.

A Class B CDL allows the driver to operate a commercial vehicle greater than 26,000 pounds. Operating a vehicle of any kind is a responsibility, but operating a Class B vehicle requires specific pre-trip inspections.

Things to Consider Before Starting Your Inspection

Before starting a Class B CDL inspection it is important to identify the item under inspection by touching the vehicle part or pointing to the aspect under inspection. The driver will need to verify that the part under inspection is in good condition. Make notice of any and all defects caught during the inspection. Logging any defect is essential to the process so that the driver will receive proper credit.

Inspect the Outside of the Truck

- Hood and Doors : Make sure the hood is not damaged and is securely locked. Doors should open and close properly. Check that the hinges aren’t broken or bent and that the seal is in place and shows no signs of damage.

- Steps: These should be mounted securely, with no excessive debris and no missing hardware.

- Fuel Tank: Make sure the fuel tank is securely mounted and not leaking. The cap should be tight and the seal intact. Check to make sure the safety chain is in place.

- Windshield: The windshield, like the lights, should be clean and not cracked or broken in any way.

- Bumper: Lastly, the bumper should be well-mounted, and in good condition. A registration plate should also be clean and visible with a valid sticker to pass inspection.

Leaks, Leans, and Lights

- Leaks: Before opening the hood, inspect under the truck. When inspecting under the truck ensure there are no wirings hanging or out of place and that there is no leaks present. There are two types of leaks that can appear. The first leak is one from the transmission or engine. The other leak could be fluid from the power steering or cooling system.

- Leans: Once confirmed that nothing is leaking, check that the truck itself isn’t leaning. If it is, that could indicate a suspension problem or low tire pressure.

- Lights: Finally, it’s time to check the lights on the top and front of the truck. The lights should not only be in working order, but the lights should be the proper color, clean, and not broken or cracked.

- Tires: Inspecting tires is a visual assessment , but it’s important to pay close attention. First, ensure that no bubbles or cuts are present. Then check that there is no space between the tires and the rims. Lastly, make sure the air pressure is correct and that the tread is worn evenly.

- Rim: The rim should show not be bent or show signs of cracks or welding repairs.

- Lug Nuts : Lug Nuts should be tightly in place, with no shiny threads or rust trails. There should be no signs of cracks or breaks. All lug nuts must be present.

- Valve Stem: Finally, the valve stem should be securely mounted, with a metal cap, and should not be damaged in any way.

Fluid Check

- Coolant Reservoir : First, take a look at the coolant reservoir. Here, the inspector is checking to make sure the coolant is at a proper level, the reservoir is mounted securely, and there are no leaks. Check the hose for signs of damage, and make sure that it, too, is securely mounted.

- Oil: Next, move on to the oil. The inspector should describe the procedure for checking the oil . First, remove the dipstick, wipe it completely clean, then re-insert the dipstick into the oil, remove, and check the level. The correct oil level is at, or below FULL but above ADD.

- Power Steering Reservoir : Finally, the inspector should check the power steering reservoir. Indicate where the dipstick is located and make sure the power steering is at the proper level. Check that the reservoir is not leaking and is securely mounted. The hose should show no signs of leaks or damages, and it too should be properly mounted.

Engine Components

- Alternator: The alternator should be securely mounted without any signs of damage. No bolts or parts should be missing. Wires must have good connections, without any fraying. Belts should have no more than ¾ inch of play and should show no signs of fraying or cuts.

- Water Pump: To locate the water pump, follow the bottom radiator hose. The pump should be securely mounted without any signs of damage or leaks. Hoses should not be leaking and must be securely attached. Belts should show no signs of being cracked, frayed, cut, or damaged in any other way. Belts should have more than ¾ inch of play.

- Air Compressor: Finally, check to make sure the air compressor is securely mounted, without any signs of damage and no audible leaks. There should be no missing bolts or parts. The compressor belt should show no signs of damage or fraying. Make sure the best has no more than ¾ inch of play.

- The Steering Shaft: Ensure that the shaft is securely mounted without excessive play and shows no signs of damage.

- The Power Steering Box: The box should be mounted to the frame without damage. Check that no leaks are present.

- The Pitman Arm: The pitman arm should be securely mounted without damage or cracks. Castle nuts and cotter pins must be present and without damage.

- Drag Link: When inspecting the drag link, make sure it is properly secured, without damage, and that the rubber bushings show no signs of damage.

- Upper and Lower Control Arms and Tie Rod: Finally, check that these are not bent or broken and that all hardware is present and securely mounted.

- Spring Mounts: There are front and rear spring mounts. Both should be securely mounted to the frame with no signs of damage.

- Leaf Springs: It’s important that the leaf springs are not t missing, cracked, or broken, but the inspector should check to make sure the leaf springs are not shifting (scissoring) either.

- Shock Absorber: Make sure the shock absorber is mounted securely and not bent or dented. Check for leaks. Lastly, make sure the rubber bushings are not worn.

- U-Bolts: U-bolts t should not be broken, cracked, missing, or loose.

- Air Hose to Brake Chamber: Check to make sure the air hose to the brake chamber is mounted securely at both ends and shows no signs of splits or cuts. Also, check for leaks.

- Brake Chamber: Check to make sure that the brake chamber shows no damage, is mounted securely and is not leaking.

- Slack Adjuster: Check that the pushrod is at a 90-degree angle to the chamber and that there is no more than 1 inch of free play at the pushrod with the brakes released. Also check for dents, breaks, and loose or missing parts.

- Brake Pads: Brake pads should show no signs of breaks or cracks and should be mounted securely. Check that the brake pads have a minimum of ¼ inch pad depth. Also check for signs of heat, such as cracking or glazing.

- Brake Drums: Check for cracks or bending, and ensure that the brake drums are mounted securely. Next, check for oil leaking from an inner oil seal. Ensure that the brake drum is free of debris and that there is no blueing from excessive heat.

Check the Cab of the Truck

- Mirrors: Mirrors inside and outside the vehicle must be checked. All mirrors should be properly adjusted, clean, and damage free.

- Wipers: Both the arms and blades on the wipers should be securely mounted with no damage. Don’t forget to check the wiper fluid.

- Heater/Defroster: Simply make sure that the heater and defroster work properly.

- Dashboard Indicator Lights: Ensure that both left and right turn signals are functioning. Then check 4-way flashers and high beams.

- Learn More About Class B CDL Pre-Trip Inspections

It may seem exhausting, having to check so many items on a large truck for Class B CDL pre-trip inspection, but it’s vital for driver safety and the safety of others on the road. Having a DOT Pre-trip Inspection Checklist ensures that every step of the inspection is followed. To make inspecting fleet vehicles, equipment, and other assets a little easier and more manageable, please don’t hesitate to contact us today to start your free trial.

Start streamlining your fleet operations with Whip Around .

- Fleet Compliance

- Fleet Inspections

- Fleet Maintenance

- Fleet Reporting & Analytics

- Help Center

- Guides & Ebooks

- Professional Services

- Training Center

- Construction

- Landscaping

- Passenger Transportation

- Trucking & Delivery

- Waste & Recycling

Connect With Us

Download Whip Around

© 2023. Whip Around. All Rights Reserved. Privacy Policy | Terms of Service

CDL Pre-Trip Inspection Test and How To Memorize It

The pre-trip is one of the things that students fear the most and fail the most. Let’s face it, the pre-trip is intimidating because there is so much stuff to memorize. The key to learning the pre-trip inspection is preparation, memorization, and repetition. Don’t go away, in this article I have exactly what you need to make sure you pass it the first time.

It is going to take time for you to memorize everything and the only way to do this is by repeating it over and over.

Hopefully, the school where you are being trained is giving you enough time to practice it everyday you are there.

I can’t stress that enough, regardless of which method you use below you need to repeat it daily and practice on your own.

Don’t expect that your run through once a day with your instructor is enough, it isn’t.

In this article I’m going to give you 8 tips that will help you memorize the pre-trip so you are able to pass it your first time and move on with your driving career.

1. REPETITION!

The only way to memorize the pre-trip is to repeat it over and over. Start with the engine area and work your way around the truck and finally inside the cab.

There is no way around consistent repetition. The more you do it the more you will memorize it. It’s just that simple.

Now that we have established how important repetition is I want you go through the rest of this list and figure out which method (or methods) works best for you and then repeat it over and over.

2. Record Someone Else

You can use YouTube to find a video of someone doing a pretrip and for the most part they work pretty well (more about YouTube later).

Take it a step further though. Ask someone (like and instructor or friend) to do a pre-trip and video record them.

While they are doing it try to use the zoom function on your camera so that you know what the parts look like and what is being checked.

Students that I come across have said that this method works really well because you have quality video and audio. Just watch your recording over and over and this stuff will be engraved in your brain.

Just make sure you are absolutely sure that the person you record knows what they are doing and are showing you everything. You don’t want to watch a video that skips anything that will be on the test.

3. Smaller Chunks

Break down the pre-trip into smaller chunks so that it is not overwhelming. If you think about memorizing everything at once it will be a daunting task.

My suggestion is you learn your air brakes first, then the inside of the cab, the engine compartment, and then the rest of the truck. You can chose any order that you want to as long as it helps you out.

Memorize each part and then tie it all together. You will find that learning the pre-trip is much easier if you do it this way.

4. Use Your Imagination

Do this while in bed before you fall asleep. Warning: the pre-trip is going to consume a lot of your attention during training, even while you sleep!

When you wake up go through a video you found on YouTube or the one you recorded (see #2) and correct any errors you made.

5. Find A Truck

It really helps if you have access to a truck. Pictures alone are not enough. Most of you are probably getting your training through a private school, company sponsored training , or community college.

All of these will give you access to an actual truck and should be taking time each day to practice the pre-trip.

Take advantage of this time with the truck to practice your pre-trip as much as possible. When class ends try to stick around to get in some extra practice, this could be the difference between passing and failing.

6. Watch A Pre-Trip Video On YouTube (not straight through)

There are a lot of videos on YouTube that you can choose from. Let me save you some time, these two (below) is the best because it has good audio and video quality, is accurate, and is easy to follow.

Don’t watch the video straight through over and over. Like I mentioned earlier you should chunk it into smaller sections.

Watch a section, pause it, and list off the names of the parts and things to look for. Play it again to see if you are getting them correct. When you finish one section go on to another section until you finish it.

Don’t move on to a new section until you have memorized the section you started. When you complete all the sections you should be able to watch the whole pre-trip and repeat everything on it from start to finish.

If you want to challenge yourself a little try mixing up the sections so that the sections that was last is now first. This will let you know if you are really memorizing everything.

7. Use A Checklist

Probably the most popular ways to memorize the pre-trip is to use a checklist. No doubt that wherever you are getting your training at is already giving you a checklist to use.

Use it. A lot.

Not all checklists are done in the same order but they should all cover the same stuff. I like this one here (printable PDF document) by the people at Trucking Truth , it’s easy to follow and is accurate.

Every possible thing that you will need to identify during the pre-trip is on this checklist.

8. Use Pictures/Diagrams

There are a ton of picture resources out there that will help you memorize the test. Just do a search for “cdl pre-trip inspection pictures” and you will find a ton of stuff.

The picture I like most are these (link to PDF) by Driver Solutions. The pictures are easy to see and distinct arrows are used to point to each part. Along with pictures is an explanation of what to look for and what to say for each individual part.

What Is The Pre-Trip Inspection?

The pre-trip inspection is an inspection of the commercial vehicle including the cab, engine compartment, and exterior.

A driver of a commercial vehicle is required, by federal law, to complete one every day before driving the vehicle and at least once in a 24 hour period. Every single time you begin driving your truck you will have to complete a pre-trip.

The purpose of it is to make sure that the vehicle is safe to drive.

This gives you a chance to get whatever is wrong fixed. If you miss something and are inspected it could result in citations by the DOT.

A lot of drivers find it to be a pain in the rear but you really need to do it every single time you drive your truck. Don’t listen to the irresponsible driver at the truck stop that tells you it’s okay to skip it. It’s not okay.

How Long Does An Inspection Take?

A pre-trip usually takes about 15-45 minutes to complete. It really depends on the type of truck you are inspecting and your experience.

After several years of driving it’s inevitable that your pre-trip is going to be quicker because you are better at doing it and you know what to look for.

As a new driver you should take your time and make sure you do it right. Make it a habit to always conduct a thorough inspection so that you run into less problems while on the road.

What To Say During The Pre-Trip Test

Knowing what to say is important during the test. There are some specific language the person testing you is going to be listening for. More than likely you already heard these phrases but here is an easy way to remember what to say:

PMS— Properly Mounted, Secure ABC— Abrasions, Bulges, Cuts CBB— Cracked, Bent, Broken

There are some tricks that you can use to make sure you say the right thing, here they are: 1 . If its mounted (almost everything is) use the words, “Properly Mounted, Secure” (PMS) 2. If its rubber use the words, “Abrasions, Bulges, Cuts” (ABC) 3. If it’s metal or another hard surface use the words, “Cracked, Bent, Broken” (CBB) 4. If it has fluid or air going through it or in it remember to say, “Not Leaking”

This language shouldn’t be new to you, hopefully the school that is training you has already taught you this stuff.

What Should You Cover During The Pre-Trip?

The areas that you should cover include the coupling system, light check, in-cab inspection, engine compartment, trailer, and drivers door fuel area. Make sure that you are prepared for all of these.

Also, keep in mind that CDL schools/classes may cover the pre-trip in different orders. It’s okay though, they all cover the same stuff. The order that you practice is probably going to be different from someones in a different school/class.

There is no correct order as long as you memorize everything.

What Will Be Tested On The Actual State Pre-trip Inspection Test?

You will be required to perform a pre-trip for the light check, the in-cab inspection, and the coupling system. These 3 areas you have to complete.

After completing those 3 areas your examiner will have you perform one of the following: the engine compartment, trailer, drivers door fuel door, or the entire vehicle.

You will not know ahead of time which one the examiner will choose. This is why it is crucial that you know all the areas.

What Else You Can Do To Prepare?

Aside from the ways listed above to help you memorize the pre-trip there are some other things you can do.

One thing you can do is try answering some practice tests like these here from Trucking Truth. There are 5 free practice tests you can take.

I really find that these practice tests reinforce what you need to know for the real test. It’s worth your time try them out just to see how you do.

What If You Fail The Pre-Trip?

If you do fail the pre-trip you are able to retake it. Make sure you know why you failed the test, ask the inspector if he/she can specifically tell you what you did wrong.

This is usually never a problem because the inspectors want you to know what you missed so that you can pass the test the next time.

One more thing, don’t be embarrassed because you didn’t pass it on your first try! This happens to a lot of people! You are not the only person that will fail the pre-trip and you won’t be the last.

Study what it is that you missed/did wrong and pass it on your second attempt.

Extra Tips For Passing The Pre-Trip Test

Probably the most common reason people fail the pre-trip is because they are nervous.

The two things that will help you out the most is to always remember that the pre-trip is a verbal contact test.

As you start walking towards the vehicle you should already be looking for any leaks under it, broken marker lights, loose mirror brakes and anything else that seems out of place.

BE VERBAL! Your number one priority is to make sure the examiner knows that you know what you are talking about. The more you talk the greater your chances are to pass the test.

Even if it might seem you are going overboard just keep going. Examiners tend to like when testers are verbal.

http://www.truthabouttrucking.com/fls/Pre_Trip_Inspection.pd

CONTACT! The second most important thing you can do is make contact with the item you are describing. For example, as you are explaining the radiator brace you need to make sure you point to or put your hand on the brace as well.

Your examiner wants to make sure that you actually know what the item is that you are explaining.

Make sure you are pointing the the correct item though! Don’t describe the radiator brace while pointing to the turbo!

Again, make sure you are VERBAL and CONTACT every single item (correctly) that you are describing.

Now go pass that test! Good luck driver!

Privacy Policy

COPYRIGHT © 2019 CDL TRAINING SPOT

404 Not found

Pre-Trip Inspection – Cab Check and Engine Start

Clutch and Gearshift Check, Engine Start

- Depress the clutch.

- Place the gearshift lever in neutral.

- Start the engine and then slowly release the clutch.

- Confirm the vehicle is in “park” and start the engine.

Oil Pressure Gauge

- Confirm that the oil pressure gauge is functioning.

- Make sure that the pressure gauge shows increasing or normal oil pressure, otherwise that the warning light goes off.

- If equipped with an oil temperature gauge, it should begin to gradually rise to a normal operating range.

Temperature Gauge

- Confirm that the temperature gauge is working.

- The temperature gauge should begin to climb to the normal operating range.

Ammeter, Voltmeter

- The gauges should show the alternator and/or generator charging; otherwise the warning light should be set off.

Air and Vacuum Gauge

- Check for proper operation and acceptable readings on the air and vacuum gauges.

Speedometer

- The speedometer should not be obscured or obviously broken.

Mirrors and Windshield

- Mirrors should be clean and adjusted properly from the inside.

- Windshield should be clean with no illegal stickers, obstructions, or damage to the glass.

Emergency Equipment

- Three red reflective triangles.

- One properly charged and rated fire extinguisher.

- Spare electrical fuses.

Steering Play

- Power steering equipped vehicles: With the engine running, play should not exceed 10 degrees (or about two inches on a 20-inch wheel) before the front left wheel barely moves when you turn the steering wheel back and forth.

- Non-power steering vehicles: Play should not exceed 10 degrees (or about two inches on a 20-inch wheel) when you turn the steering wheel back and forth.

Wipers and Washers

- Check that the wiper arms and blades are not damaged and operate smoothly.

- Windshield washers must operate correctly if the vehicle is equipped.

Lighting Indicators

- Left turn signal

- Right turn signal

- 4-way emergency flashers

- High beam headlight

- Check that air horn and/or electric horn are operational.

Heater and Defroster

- Test that the heater and defroster works.

Safety Belt

- Check that the safety belt is securely mounted, adjusts, and latches properly.

Lights and Reflectors

- Clearance lights (red on rear, amber elsewhere)

- Headlights (high and low beams)

- Turn signals

- 4-way flashers

- Brake lights

- Red reflectors (on rear) and amber reflectors (elsewhere)

The Five (5) Components of the Pre-Trip Inspection

Engine compartment, cab check and engine start, brake check, external cab, trailer (for bobtail trucks), study and training guides, download the 5 components of the pre-trip inspection, pre-trip inspection study guide... know exactly what you need to pass the exam, pre-trip training dvd.

Learn more... order a High Quality Pre-Trip Inspection Training DVD for just $45.00. See a sample online .

Students' Satisfaction

Applause from our students.

Watch a video testimonial and read about how happy GSF's bus driving students are with our classroom instruction, driver training and comprehensive service.

Become a Professional Driver

Get your license to drive a commercial vehicle

Home | CDL A | CDL B | Contact Us | Privacy Policy

School Catalog, Annual Report and Student Performance Fact Sheets

GSF Driving & Truck Training School Truck and Bus Driver Training

(323) 231-3311 | 731 East Slauson Avenue · Los Angeles, CA 90011 (818) 364-6600 | 16205-16211 Filbert Street · Sylmar, CA 91342 [email protected]

Licensed under the California Department of Consumer Affair's Bureau of Private Postsecondary Education, School Code No. 83344596 Copyright © 2009 GSF Driving & Truck Training School. All rights reserved.

Dump Truck CDL Class B Pre-Trip Inspection

Pre-trip inspection dump truck class b.

The Class B Commercial Driver’s License (CDL) pre-trip inspection will have approximately 80 items to be checked on a dump truck with air brakes. The number of checks will be based on the actual vehicle’s installed equipment. The following procedures/items would be the same for other Class B vehicle types (Gross Vehicle Weight Rating of straight trucks weighing 26,001 lbs. or more) such as bucket trucks, garbage trucks, flatbeds, and other straight trucks.

Here is a procedural training video demonstrating the requirements and best practices to help prepare you for successfully completing the Pre-Trip Inspection portion of the CDL Class B (Dump Truck). Below the video is a line item checklist you can also use for study.

To earn your Commercial Driver’s License, you must pass a series of tests. One of the first tests is the Pre-Trip Inspection. In your working life after earning your CDL, you would actually accomplish each checklist item — physically check oil level, tire pressure, etc. But, while testing to earn your CDL, you only need to name and point to or touch each item, and fully explain to the examiner what you are inspecting (for the In-Cab portion of the Pre-Trip Inspection Test, you must physically demonstrate each item).

You are being graded to ensure you know what to check each part for, and not that you just know the names of the parts. You will have to check each item as outlined.

Whereas the checklist below is a good guide to follow, there is no specific order or sequence to the test. You just need to ensure you complete every item.

Pre-Trip Inspection Class B with Air Brakes Checklist Items

This checklist order starts in the front of the vehicle and inspects only the axles on the driver’s side of the truck. The test requires you to only inspect the driver side unless the item is only on the passenger side (parts in engine compartment, exhaust).

Front of Vehicle

- securely mounted

- not broken or cracked

- amber in color

- Clear and clean

- ensure no leaks or oil puddles

Engine Compartment

- Locate the oil dipstick

- make sure level is between add and full

- locate coolant reservoir

- ensure level is sufficient for operation, between hot and cold mark

- not leaking

- if no reservoir, verbally describe how to remove radiator cap and check coolant

- ensure level is between add and full

- must say if it is gear or belt driven

- working properly

- not damaged

- securely mounted, bolts tight

- belt driven

- belt, not cracked or frayed, and tension is between ½” and ¾”

- wire secure into back of alternator

- belt, not cracked or frayed, tension is between ½” and ¾”

- secure to engine, bolts tight

- hoses secure, not leaking

- if belt driven, belt not cracked or frayed, tension is between ½” and ¾”

- check under vehicle for oil puddles

- check engine for leaks

- check hoses for splits and cuts

- ensure all clamps are tight

- check all hoses for leaks

- make sure to check both hoses on both sides of engine for leaks

Front Truck Axle

- secure, bolts tight

- not cut, pinched or leaking

- fittings are secure not cracked or broken

- not bent, bolts tight, no cracks, cotter pins in place

- sockets are not worn or loose

- must check from steering wheel to steering box and from steering box to axle.

- none broken

- all in alignment

- not shifted

- not broke or rusted

- check front and rear mount for cracks, rust

- check for tight or missing bolts

- make sure bushings are not torn or missing

- not cracked, bend, or broke

- bolts tight

- not kinked, cut, swollen or leaking

- fittings secure

- not bent, broke or leaking

- not cracked dented, rusted or leaking

- clamp is secure, tight and in place

- pins in place holding slack adjuster to push rod

- straight, not broken

- no more than 1”adjustment (movement) on the push rod

- not bent or broken

- no holes, cracks or dents

- smooth surface

- no signs of grease or oil

- shoes are sufficient, more than ¼” pad

- no cracks, no chipped pads

- no fluid, grease or oil

- 4/32” tread depth

- no cuts or bubbles on side walls

- check top of tire for even wear and flat spots

- check pressure with gauge

- check valve stem is not cracked, broke, leaking or twisted and secured with cap

- no rust trails

- no aftermarket welds

- none missing

- no signs of rust trails

- no cracks or distortion from lug bolt holes

- no loose or missing bolts

- proper fluid level (if sight glass)

Side of Cab and Vehicle

- not cracked or broken

- door hinges are secure, bolts tight

- handle works, no damage to side

- seal is intact and not torn

- opens and closes properly

- securely mounted, brackets not damages, bolts in place

- mirror is not broke and clean

- securely mounted, bolts

- no fluid or debris on steps

- straps are secure

- cap is on tight

- must check tank & cap for leaking

- no signs of soot (leaking)

- all clamps are tight

- must check hole exhaust system from turbo to top of stack

- not peeling or cracked

Under the Vehicle

- bolts are all tight

- must also check cross members for same

- straight, no cracks, bolts are tight

- must check u-joint bolts and u-joint is free of foreign objects

Rear Truck Axle

- check front and rear mount for cracks

- not cracked

- bushing not torn or missing

- not kinked, cut, swollen

- fitting is secure

- not bent, broke

- not cracked or rusted or leaking

- no more than 1” adjustment (movement) on the push rod with brakes released (double chamber)

- no holes, cracks, or dents

- no cracked or chipped pads

- 2/32” tread depth

- check pressure with a gauge

- check valve stem is not cracked, secure, leaking or twisted and cap is in place

- none missing, not loose, no signs of rust trails

- must check there is no debris between tires

- tires are evenly spaced

- rims flush (butted) together

Rear of Vehicle

- mud flaps not torn

- no damage/ holes

- fits to the bed

- hinges are secure; bolts tight

- if equipped, seal intact; not torn

- red in color

In-Cab Compartment/Engine Start (need to demonstrate all mechanisms)

- spare fuses or breakers (whichever truck is equipped with)

- must work properly

- put on seat belt; must click secure and fit properly

- not cut, frayed or torn

- securely mounted at seat, shoulder and floor ( all points )

- After turning key to "On" position, ensure ABS light turns on and then turns off.

- After turning key to "On" position, ensure DEF light turns on and then turns off.

- on dash, check left & right turn arrow

- 4 way flashers

- high/low beam indicator

- check temperature gauge for operation and in safe range

- check voltmeter for operation and in safe range

- needle indication charging

- check oil pressure gauge for operation and in safe range

- working properly, pressure builds to 120 PSI or governor cut out or purge

- must be clean

- no cracks or chips

- no obstructions; stickers

- seal is secure with no leaks

- no stickers

- mirrors are adjusted

- operate properly (must turn on)

- rubber blades are not cracked

- good contact to windshield

- medal arms are secure, no damage

- washer fluid operates (squirts)

- blow air and electric horn

- must turn to hot and feel for air from vents

- turn on defroster to make sure they work properly

- feel for air to blow from vent at windshield

- push in clutch & make sure shifter is in neutral before starting engine

- if automatic transmission make sure vehicle is in neutral

- check parking brake by applying and putting truck in low gear and try to move (lug engine)

- must check both tractor and trailer parking brake individually

- pull forward at 5 mph and stop with foot brake

- ensure steering wheel does not pull left or right

- roll driver’s side window down (listen for leaks)

- build air pressure to ~120 PSI, governor cut-off (to purge)

- turn off engine then turn key to on position

- release parking brake, push in

- apply foot brake & keep pressure and listen , applied for 1 minute-cannot lose more than 3 pounds in 1 minute (must hold for full, timed minute)

- say that low air buzzer will come on at ~55 to 60 PSI; pump foot brake (fan) so buzzer will sound

- say that parking brake will automatically engage at approximately 20-30 PSI, continue pumping foot brake (fan) until parking brake engages.

Exterior Light Operation Check

In Florida, you may ask the examiner to assist in checking the external lights. You must tell the examiner exactly which lights they would check (headlight high and low beam; right and left turn signals; 4-Way flashers; Clearance Lights)

Remember, lights are amber in color on the front, and red in color on the rear (all lights, must say color and describe light condition)

- Lights (front of vehicle AMBER )-head lights (high & low beam), right/left turn signal, 4 way flashers, clearance, must turn on, clean, not broken, operating properly

- Lights (front side of vehicle AMBER )-right/left turn signal, put on emergency, flashers, make sure working, amber lenses, not broken, clean

- Lights (rear of vehicle RED )-right/left turn signal, put on 4 way flashers, clearance and brake lights, red lenses, not broken, clean.

Site Navigation

- SMG of Crystal River

- CDL Testing

CDL Testing and Prep

- Steps to Getting Your CDL

- Class A CDL Pre-Trip Inspection w/Air

- Class A CDL Pre-Trip Inspection w/o Air

- Dump Truck CDL Pre-Trip Inspection Class B

- Passenger Bus CDL Pre-Trip Inspection Class B

- Driver's On-road Practical Test

- Commercial Driving Behavior

- CDL Driver Control Skills Test

- Instructional Videos

All CDL Testing & Training

All SMG CDL testing and training is initiated and completed at Interstate Commercial Driving School (ICDS) located at:

SMG Contact Information:

Tel: (352)795-7170

Fax: (352)795-8723

© SMG, Inc . All Rights Reserved.

Elektrostal Tourism

- Things To Do in Elektrostal

- Elektrostal Itineraries

- Elektrostal Hotels

Elektrostal Trip Planner

Plan your customized day by day trip plan for Elektrostal. Choose from various experinces categories as adventure, romantic and family and kids friendly for your trip using using Elektrostal trip planner.

- THINGS TO DO

- HOW TO REACH

- TOP RESTAURANTS

- Moscow Trip Planner

- Yaroslavl Oblast Trip Planner

View prices for your travel dates

- Excellent 18

- Very Good 9

- All languages ( 43 )

- Russian ( 37 )

- English ( 4 )

- German ( 1 )

- Italian ( 1 )

" DIR: West; bigger nice evening sun but louder due to main street DIR:East; Quiter, very bright in the morning if sun rises "

Own or manage this property? Claim your listing for free to respond to reviews, update your profile and much more.

APELSIN HOTEL - Reviews (Elektrostal, Russia)

Na Ulitse Yalagina 13B Apartments

Property Policies

Frequently asked questions, how much does it cost to stay at na ulitse yalagina 13b apartments, what are the check-in and check-out times at na ulitse yalagina 13b apartments, does na ulitse yalagina 13b apartments provide airport transfer services, what amenities and services does na ulitse yalagina 13b apartments have, does na ulitse yalagina 13b apartments have a swimming pool, does na ulitse yalagina 13b apartments have fitness amenities, does na ulitse yalagina 13b apartments provide wi-fi, does na ulitse yalagina 13b apartments have non-smoking rooms, does na ulitse yalagina 13b apartments have a restaurant, is parking available at na ulitse yalagina 13b apartments, popular hotels, explore more.

IMAGES

VIDEO

COMMENTS

Class B Pre-Trip Inspection Point to, or touch, every item that you are inspecting. Tell the tester how you know that the part you are ... This three page diagram will simplify the Class B CDL Pre-Trip inspection. Keywords: Pre-Trip Inspection; CDL Test; Class B,air brake,test,skills Created Date: 5/21/2016 8:15:04 PM ...

PRE-TRIP INSPECTION GUIDE TT iv Pre-Trip Inspection Terminology: PMS - Properly Mounted, Secure CBB - Cracked, Bent, Broken ABC - Abrasions, Bulges, Cuts A few general tips: If its rubber - ABC If it has fluid/air going through it or in it - Not leaking. If its mounted (almost everything is)- PMS If its metal or some other hard surface- CBB

Practical exams. Skills test. Pre-trip inspection. TSA background check. Retake policy. CDL Maintenance. ELDT Training & Certification. CDL how-to guides. Learn how to conduct thorough pre-trip inspections with our guide, a critical component for commercial vehicle safety.

Study with Quizlet and memorize flashcards containing terms like Front of Bus, Front Axle - Front Wheel, Steering Parts and more. ... CDL Class B Pre Trip Inspection. 61 terms. MrSwangAtEase. Preview. Machine Tool Test 2. 113 terms. Naruto_Shippuden4. Preview. ES Unit 5 test vocab. Teacher 13 terms. mrssoutherland14.

Printable Pre Trip Inspection Checklist (PDF) CDL Manual. CDL General Knowledge Practice Test. Pre Trip Inspection Practice Test. CDL HAZMAT Endorsement Practice Test. Edited for 2024 on 12/5/23. Complete CDL pre-trip inspection checklist with online reference and study guide plus a free PDF pre trip inspection checklist to print.

The DMV Driving Test will be administered late in the CDL learning process, right before you get your license. It consists of the Vehicle Inspection Test, the Basic Control Skills Test, and the Road Test.Note that the Vehicle Inspection Test was previously called the "Pre-Trip Inspection Test". In this study guide is more information about all of these tests, as well as some tips for ...

Pre-Trip Inspection Study Guide. Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam. Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will ...

These are the very things you'll find when studying and testing. One of the most important tasks is a CDL pre-trip inspection. Not only does this keep you and everyone else on the road safer, but it is required to remain compliant with . It also keeps you in-the-know about how your truck is performing and if there are any issues that need to ...

There are specific pre-trip inspections that need to be completed in order to successfully operate a Class B vehicle. Knowledge is power in the fleet industry and forgetting important details can be consequential. A Class B CDL allows the driver to operate a commercial vehicle greater than 26,000 pounds. Operating a vehicle of any kind is a ...

it. This guide offers a Wording section and parts A, B and C of the Pre-Trip. For your skills test, you may get one of these 3 or you may get part D, which means you must do the ENTIRE Pre-trip. Use your "free-time" to study. There is no down time in truck driving. Your commitment to the program reflects your success.

Use our CDL pre-trip inspection checklist and practice test as your pre trip inspection study guide. The practice test has sample questions about checking items in the engine compartment, driver door fuel area, trailer, in the cab and more. CDL Pre Trip Inspection Checklist & PDF File. Class A Pre Trip Inspection Practice Test.

Studying our simplified Class-A pre-trip inspection checklist, taking classes at a local CDL training school, and watching videos will prepare you. Each company's pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections. CDL Pre-Trip ...

1. REPETITION! The only way to memorize the pre-trip is to repeat it over and over. Start with the engine area and work your way around the truck and finally inside the cab. There is no way around consistent repetition. The more you do it the more you will memorize it. It's just that simple.

Our Pre-Trip Inspection Study How has everything you need on prepare since the Class A CDL Pre-Trip Inspection Exam. Our studies guide desire cover the pre-trip inspection phraseology when well as a durchziehen tabbed of all of the parts you will be inspection on and your. For each part you will be inspecting there will also can a list of ...

Place the gearshift lever in neutral. Start the engine and then slowly release the clutch. Confirm the vehicle is in "park" and start the engine. Oil Pressure Gauge. Confirm that the oil pressure gauge is functioning. Make sure that the pressure gauge shows increasing or normal oil pressure, otherwise that the warning light goes off.

a) the coolant temperature gauge should begin a gradual rise to normal. You are stopped, You want to start driving uphill. You should: a) partially engage the clutch and then release the parking brake. b) engage the clutch and accelerate quickly. c) keep the trailer brake hand valve applied until you reach 20 MPH.

The Class B Commercial Driver's License (CDL) pre-trip inspection will have approximately 80 items to be checked on a dump truck with air brakes. The number of checks will be based on the actual vehicle's installed equipment. The following procedures/items would be the same for other Class B vehicle types (Gross Vehicle Weight Rating of ...

Answer 1 of 9: Dear Fellow Travellers We're thinking of visiting Suzdal on a one-day trip from Moscow this mid-August. We did our homework, and found the best way is to go to Vladimir by train and take a bus to Suzdal. We also checked the fare/timetable...

From budgeting tips to finding the best spots, this travel guide has got all the insider information to explore Elektrostal like a local. This city is located in the close proximity of a major city Moscow, Russia. ... Don't just take a trip, let the trip take you! Have a enjoyable time at Elektrostal. Elektrostal Trip Planner.

Total number of rooms reached 81. The hotel has got a number of significant advantages: comfortable location, luxury and standard hotel rooms, free parking, moderate prices and highly qualified staff. According the experts in the tourism and hospitality business the hotel is reckoned the leading middle class hotel in Moscow region.

LocationIf you want to feel like you're at home no matter where you are, choose this — apartment «Na Ulitse Yalagina 13A Apartments» is located in Elektrostal. This apartment is located in 3 km from the city center. You can take a walk and explore the neighbourhood area of the apartment — ZIL Culture Center, Saint Basil's Cathedral and ...